Comprehensive pneumatic measuring device for link rod

A pneumatic measurement and connecting rod technology, applied in the direction of measuring devices, fluid devices, instruments, etc., can solve the problems of low measurement efficiency, high labor intensity, large measurement error, etc., achieve high measurement efficiency, high measurement accuracy, and reduce detection cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

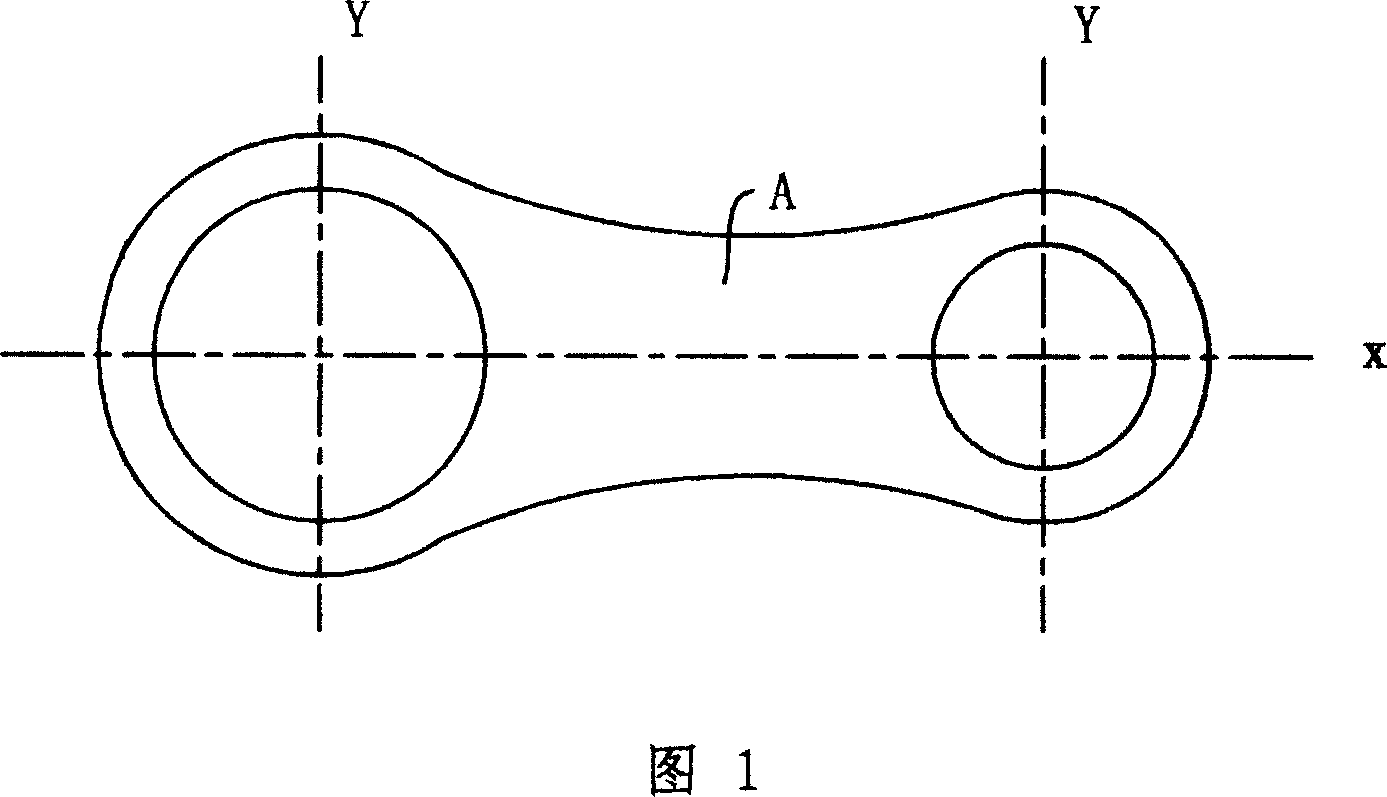

[0020] Fig. 1 is a top view of a connecting rod A of an internal combustion engine. For the convenience of description, the direction passing through the centerlines of the two holes is defined as the X direction, and the direction perpendicular to the centerlines of the two holes is defined as the Y direction.

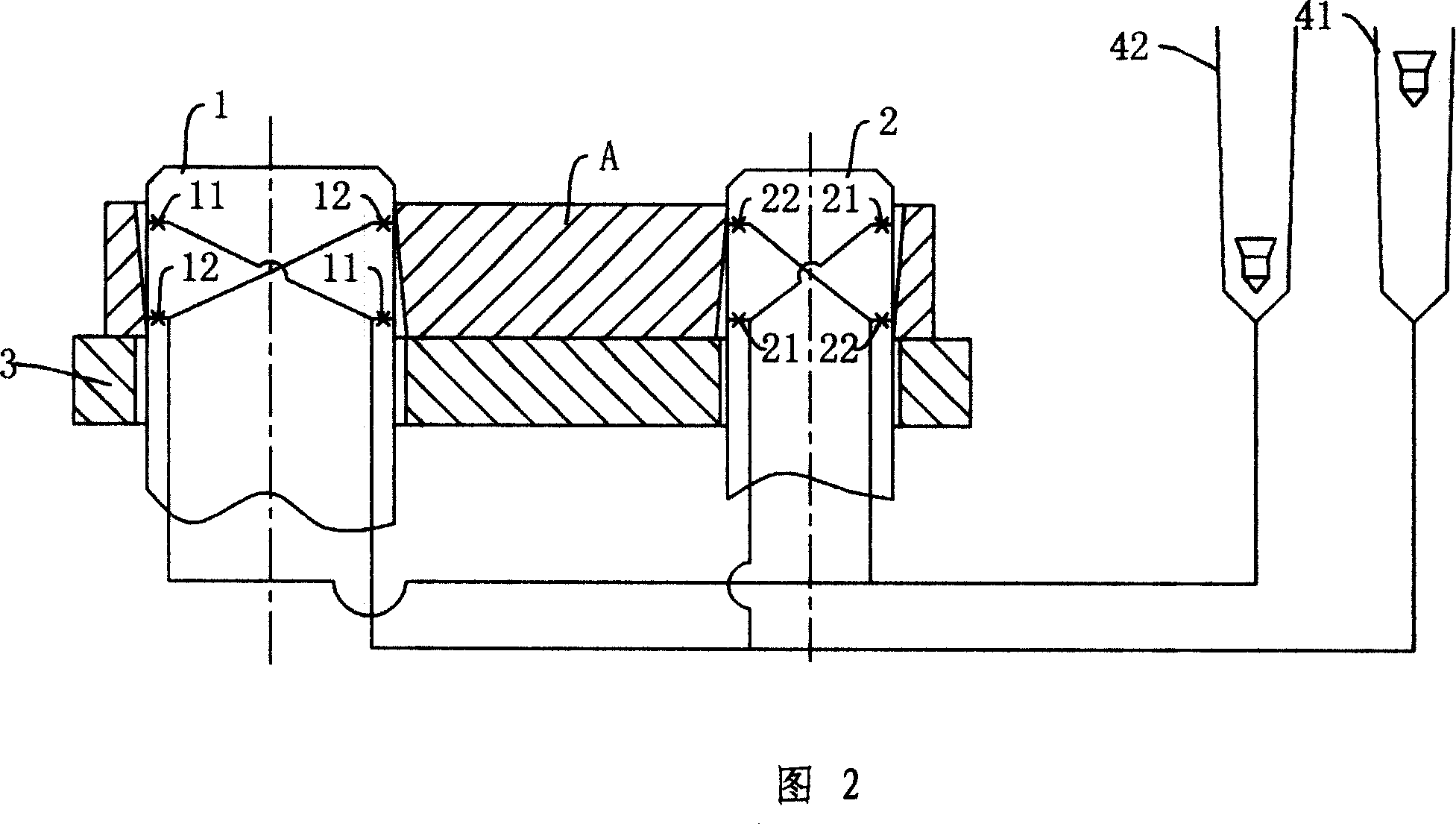

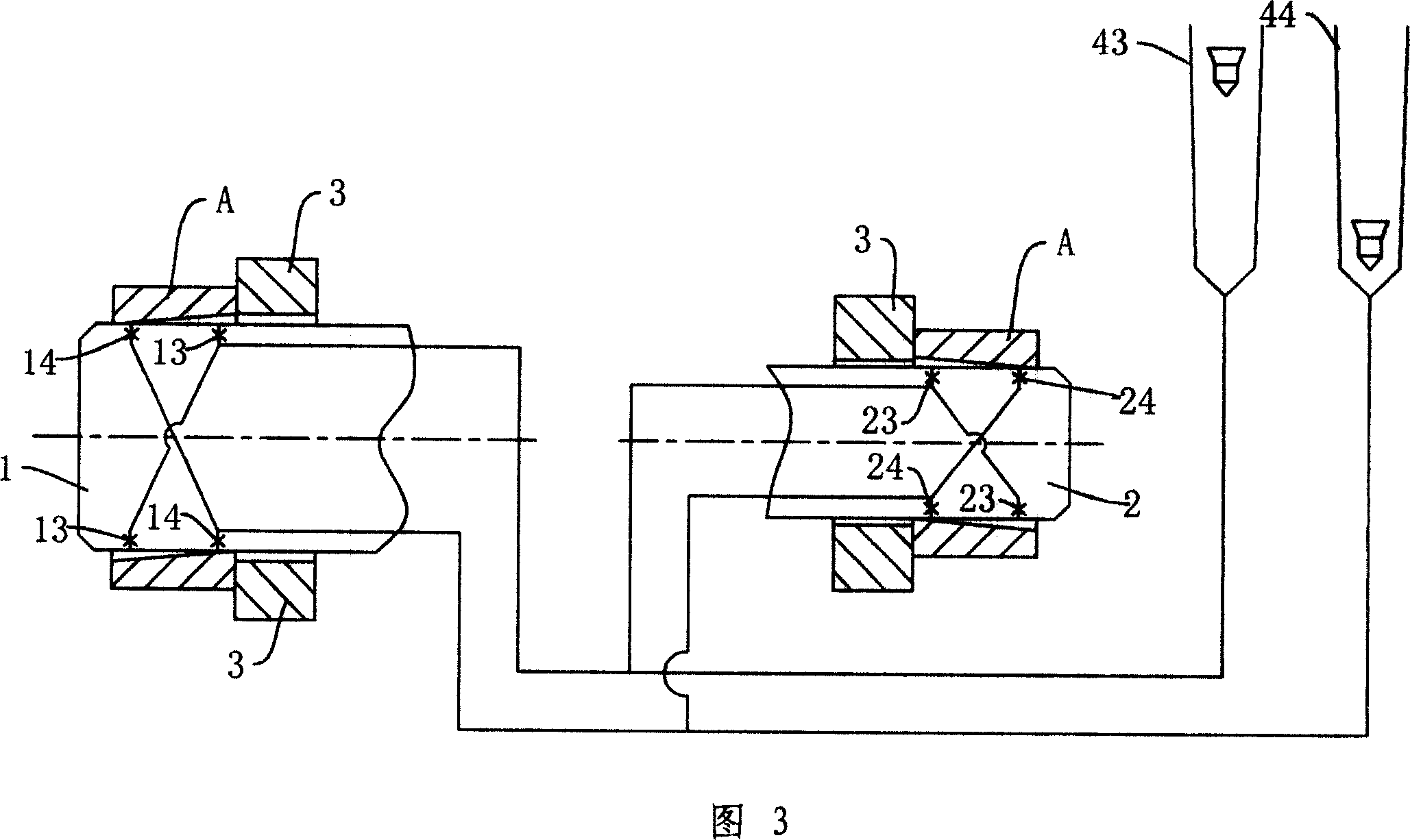

[0021] The present invention mainly includes two measuring heads, which are respectively provided with several measuring branches that can be connected with corresponding data indicating units of the pneumatic measuring instrument, and these data indicating units can intuitively measure the two measuring heads. data is displayed. The pneumatic measuring instrument adopts a buoy-type pneumatic measuring instrument, and of course a digital pneumatic measuring instrument can also be used. The data indication unit of the buoy-type pneumatic measuring instrument usually adopts such a structure, and a buoy is set in a glass tube with a scale. One end of the glass tube is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com