Mobile phone thimble-type RF calibration clamp

A radio frequency calibration, thimble-type technology, applied in the direction of frequency measurement devices, transmission monitoring, instruments, etc., can solve the problem that the absolute accuracy of the device cannot meet the performance targets of equipment frequency, power level and other parameters, and achieve reliable performance and avoid short circuit , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

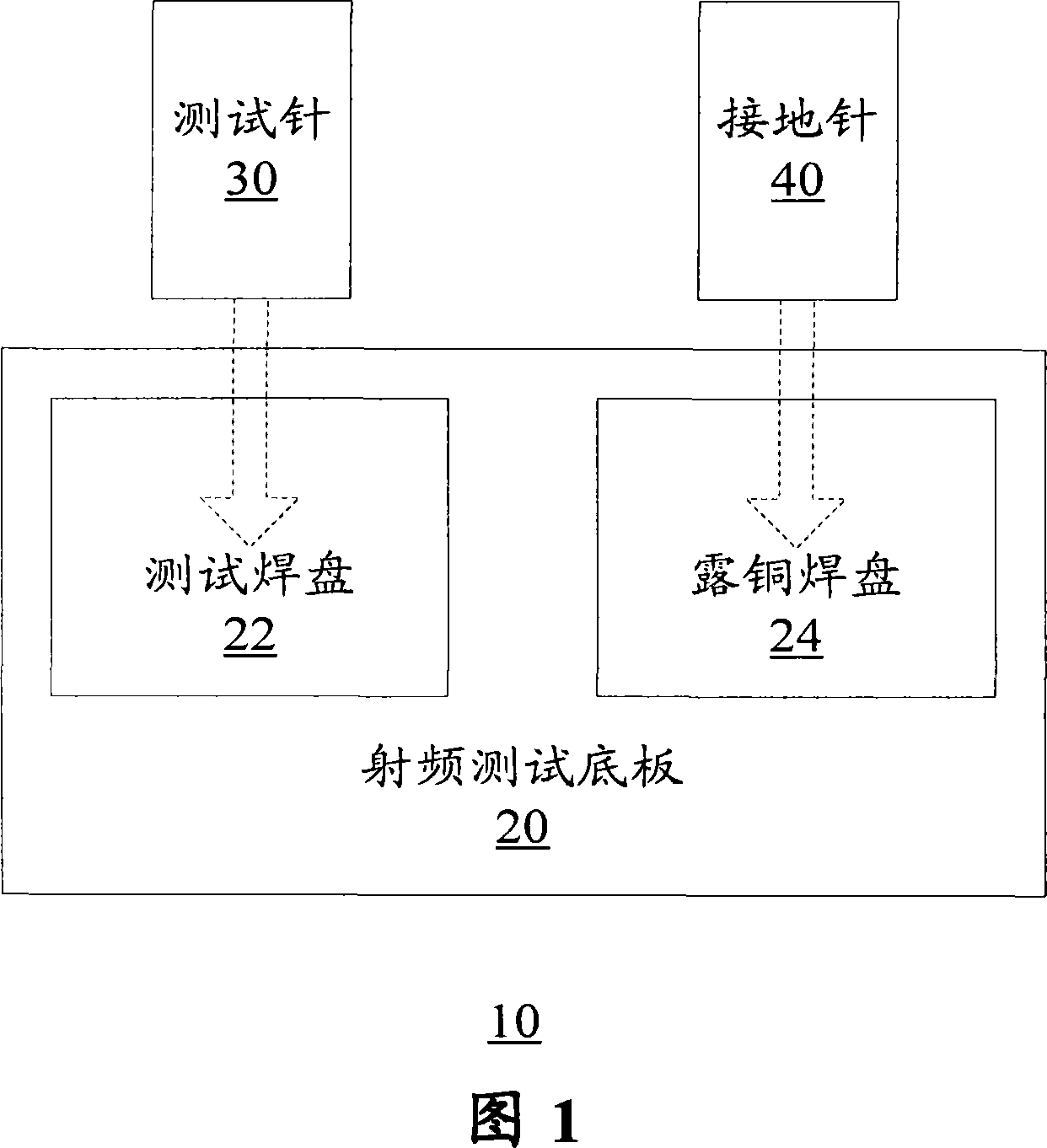

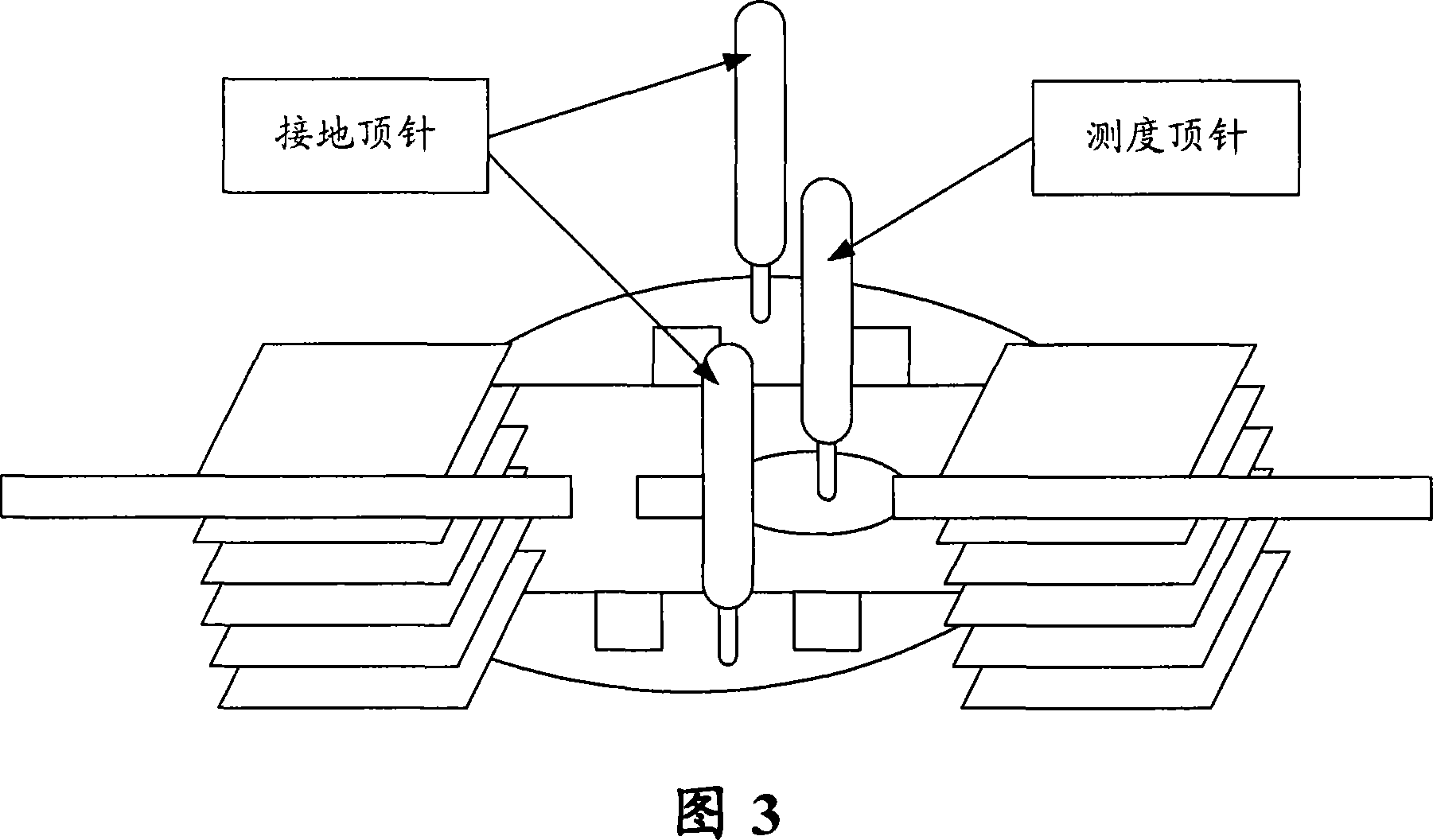

[0023] Referring to Fig. 1, mobile phone thimble type radio frequency calibration fixture 10 according to the present invention comprises: radio frequency test base plate 20, is positioned on mobile phone, comprises test pad 22 and exposed copper pad 24; Test needle 30, is used for carrying out radio frequency test, when carrying out During radio frequency calibration, the pressure is pressed on the test pad 22; and the ground pin 40 is used for grounding, and when the radio frequency calibration is performed, the pressure is pressed on the exposed copper pad 24.

[0024] Preferably, the test pin 30 and the ground pin 40 are pogo pins.

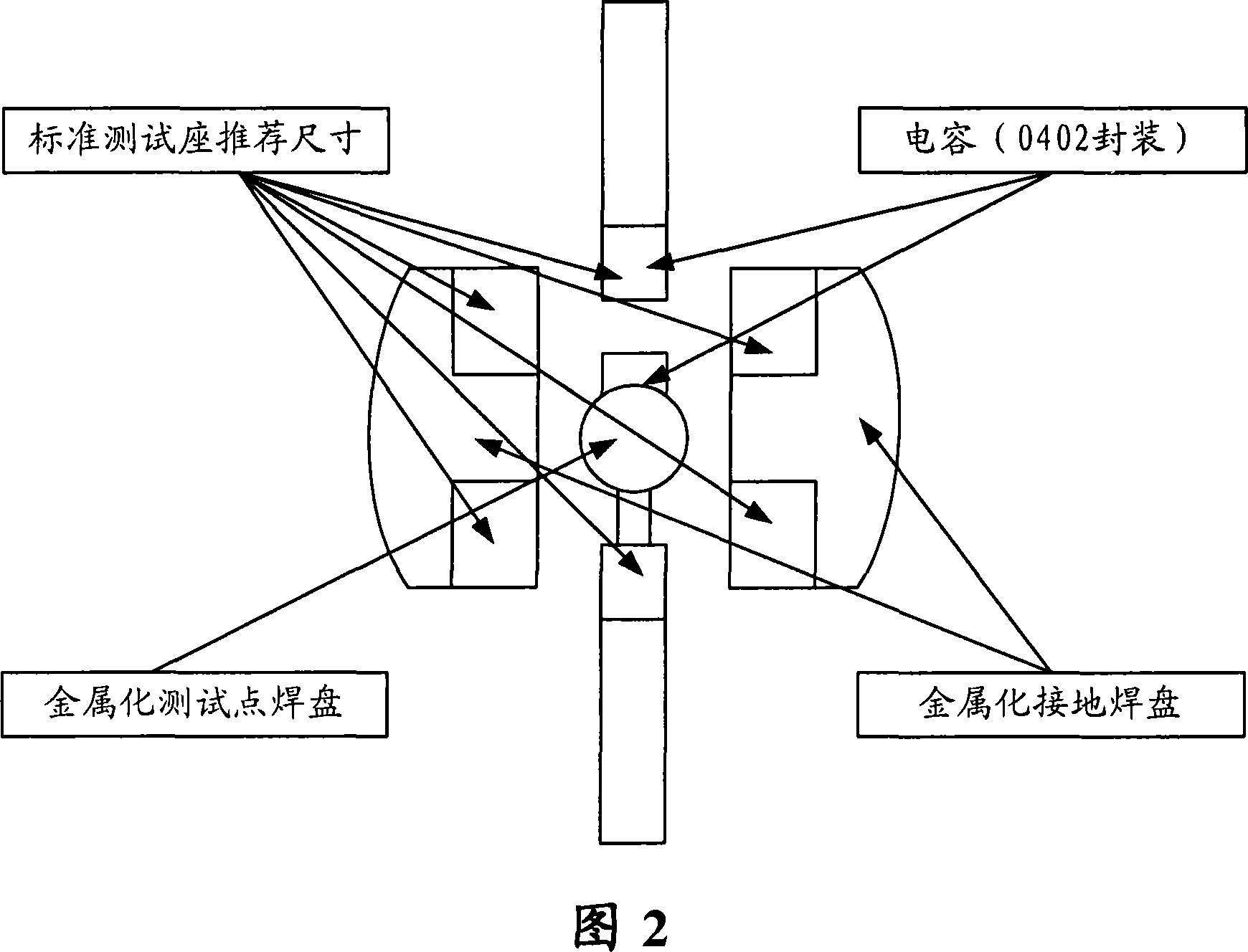

[0025] Preferably, the mobile phone thimble radio frequency calibration fixture 10 includes two grounding pins 40 . The test pad 22 is located at the center of the RF test base 20 . The two exposed copper pads 24 are located o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com