System for making chopped strands

A yarn and cutting wheel technology, applied in the yarn system, glass filament, and cutting thermoplastic material yarn field, can solve the problems of hindering the user's walking and intervention, large volume, etc., to reduce manpower intervention, increase productivity, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

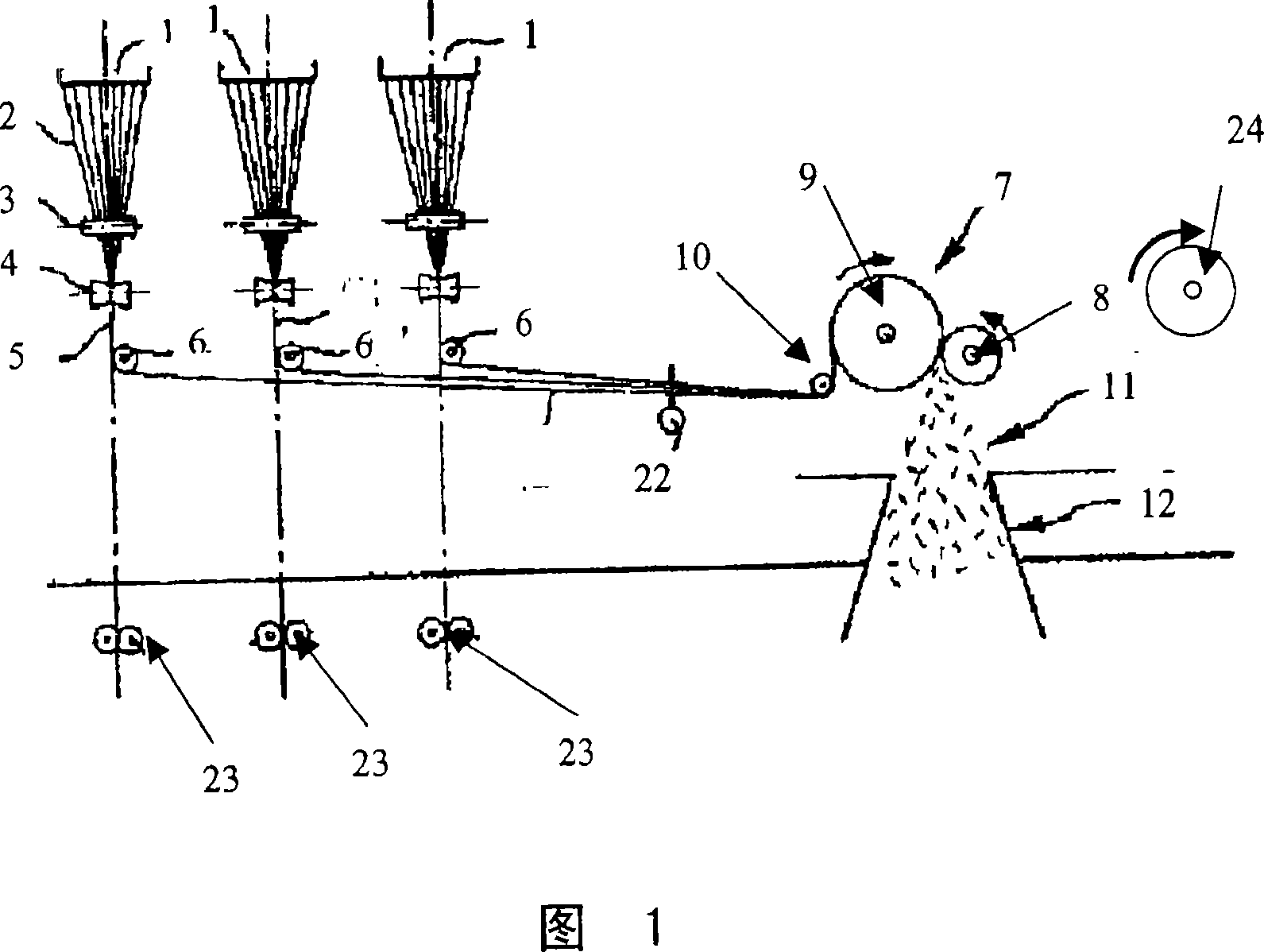

[0043] On FIG. 1 , a prior art system is shown schematically, comprising at least one spinneret 1 , which is supplied in a known manner with molten glass or glass spheres delivered by a supply device not shown. The spinneret, for example made of a platinum-rhodium alloy, is generally heated by the Joule effect. The spinneret is equipped in its lower part with a plurality of holes from which a plurality of filaments 2 can be drawn off mechanically (a plurality is shown here with a dashed line).

[0044] Said filaments 2 are generally subjected to sizing, i.e. to chemical treatment, so that a product is applied to said filaments, which, through sizing rollers 3, causes yarn binding and sufficient lubrication and subsequent processing and Enhanced usage / mold compatibility.

[0045]The filaments from one spinneret are then joined by engaging guide wheels 4 into at least one yarn 5 which is deflected by, for example, a diverting or driving guide wheel 6 so as to convey said filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com