Ultrathin wall rolling bearing

A rolling bearing, ultra-thin-wall technology, applied in rolling contact bearings, bearings, bearings in rotating motion, etc., can solve problems such as short life and achieve the effect of preventing abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

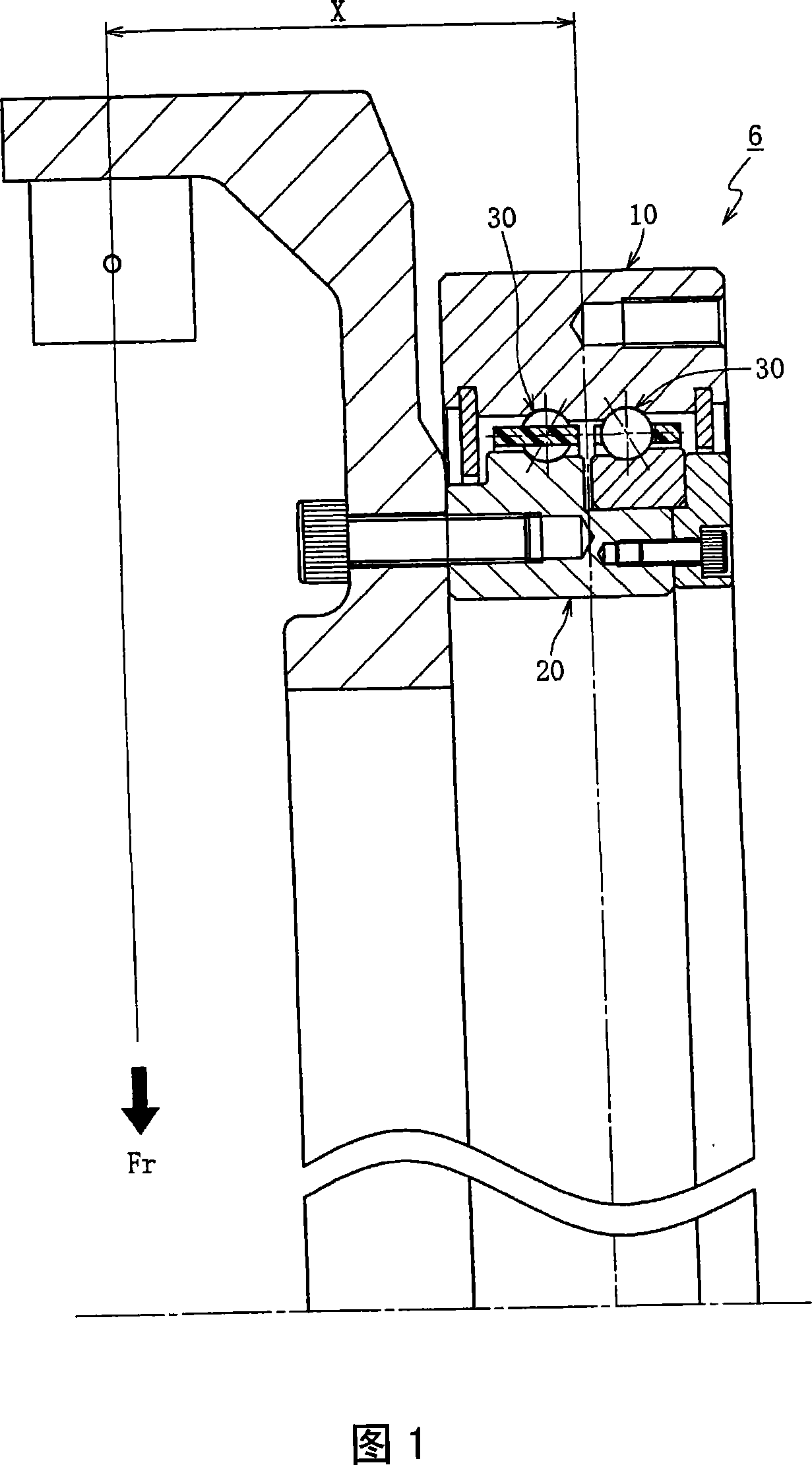

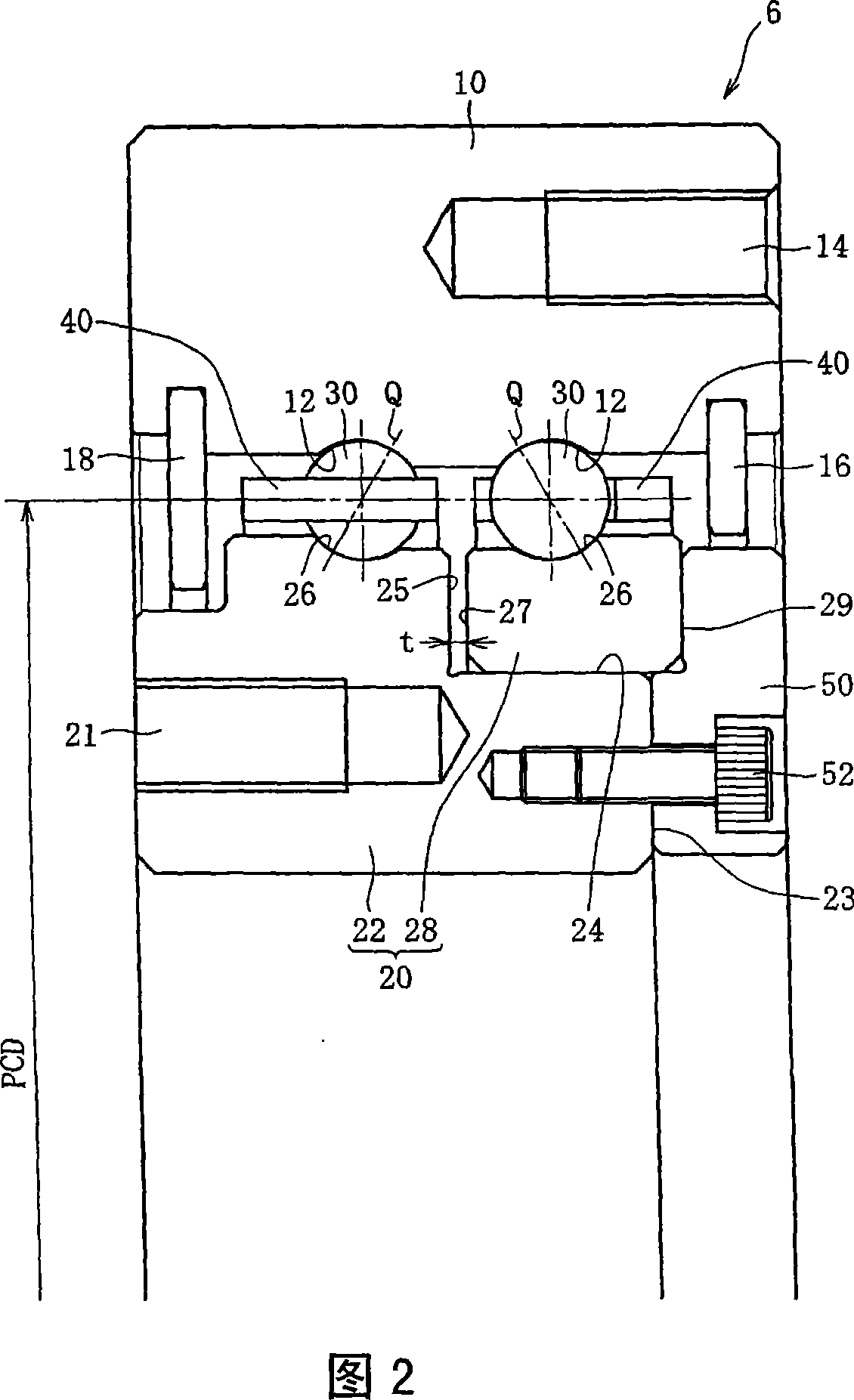

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Here, FIG. 1 shows the structure of the bearing 6 of the CT scanner shown in FIG. 4 , and FIG. 2 is an enlarged view of main parts in FIG. 1 .

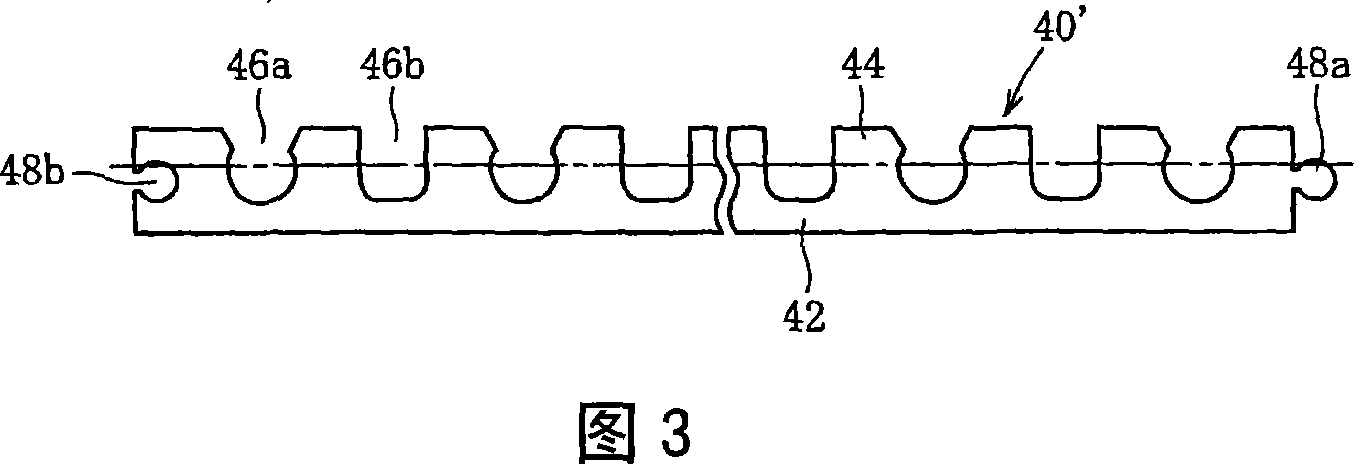

[0025] As shown in FIG. 2, the main components of the bearing 6 include an annular outer member 10, an annular inner member 20 concentrically disposed on the inner peripheral side of the outer member 10, and a ring-shaped inner member 20 sandwiched between the outer members. Multiple rows of rolling elements 30 between 10 and the inner member 20, cages 40 that hold the rolling elements 30 of each row at predetermined intervals in the circumferential direction, and seal rings 16 that seal the openings at both ends of the bearing, 18. And a preload imparting member S for imparting preload to the bearing.

[0026] This bearing 6 is a multi-row bearing in which the number of rows of rolling elements 30 is two. Among them, balls 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com