Technique of extracting polysaccharide in rosa laevigata michx

An extraction process, the technology of Rosa roxburghii, applied in the field of extraction process of natural plants, can solve the problems of low recovery rate, low purity, complicated operation, etc., and achieve the effect of high recovery rate, high purity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Rough extraction process: wash 1 kg of Rosa roxa raw material, dry at 50°C for 48 hours, crush, pass through a 40-mesh sieve, add 2L of petroleum ether, reflux at 60-65°C for 2 hours, cool to room temperature, add a weight concentration of 80 % ethanol 1.5L, stand for 3h, evaporate the solvent, add the product to 10L of water, reflux at 90-95°C for 4h, cool to room temperature, filter, and concentrate the filtrate to 1L at a temperature of 60°C and a pressure of -1.9Mpa .

[0021] Deproteinization process: deproteinize 1L of concentrated solution by Sevage method 6 times, add 3.5L of ethanol to the separated solution for alcohol analysis, add 1L of ether and 1L of acetone to wash the precipitate, and vacuum freeze-dry the precipitate to obtain mixed polysaccharides (RPs) 165g.

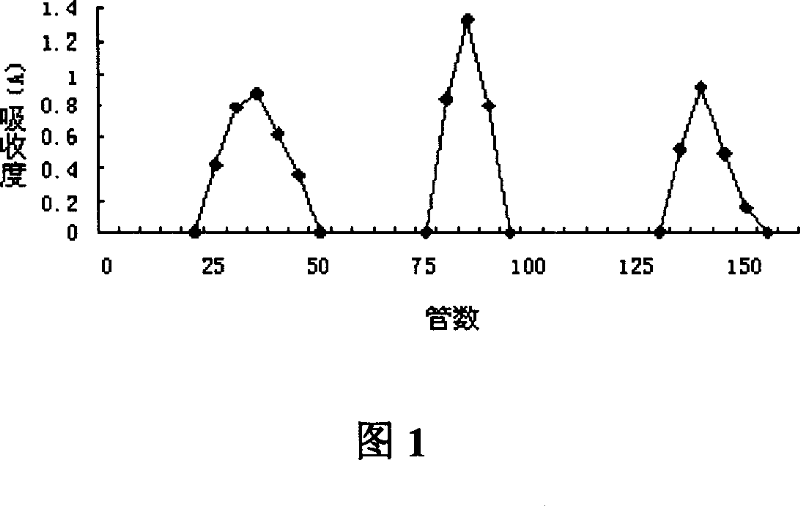

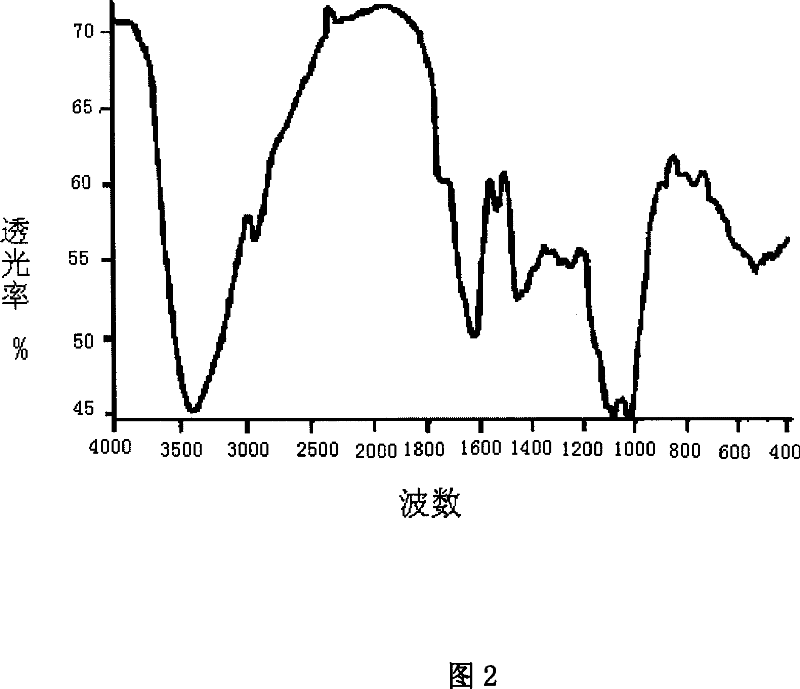

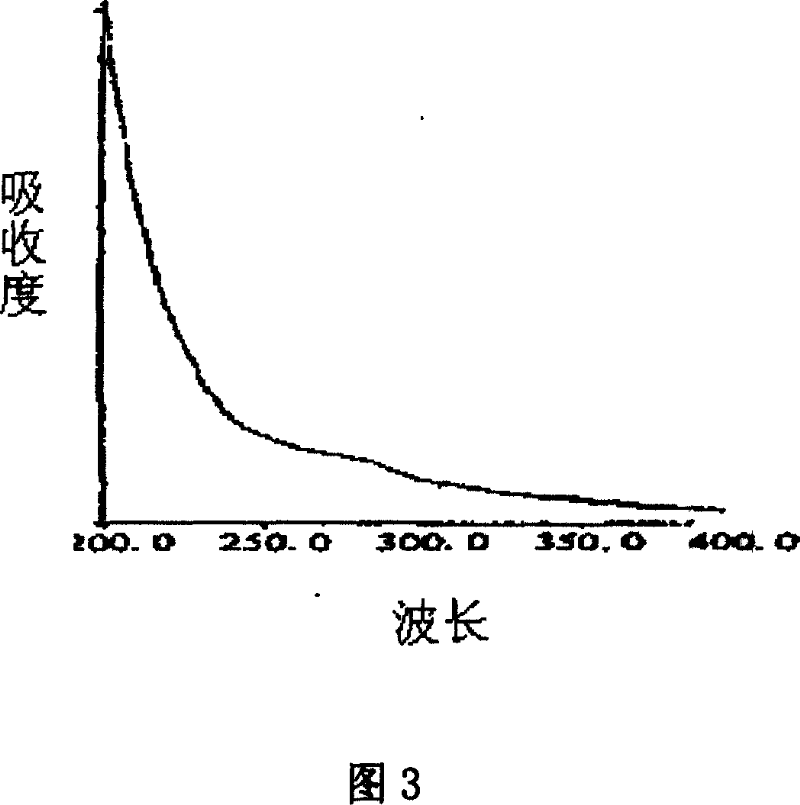

[0022] Classification process: Diethylaminoethyl cellulose is used as filler, the mass ratio of diethylaminoethyl cellulose to mixed polysaccharides (RPs) is 10:1, and the flow rate is 1.5ml / mi...

Embodiment 2

[0026] Rough extraction process: wash 1 kg of Rosa roxa raw material, dry at 50°C for 48 hours, crush, pass through a 40-mesh sieve, add 2L of petroleum ether, reflux at 60-65°C for 2 hours, cool to room temperature, add a weight concentration of 80 % ethanol 1.5L, stand for 3h, evaporate the solvent, add the product to 10L of water, reflux at 90-95°C for 4h, cool to room temperature, filter, and concentrate the filtrate to 1L at a temperature of 60°C and a pressure of -1.9Mpa .

[0027] Deproteinization process: deproteinize 1L of concentrated solution by Sevage method 7 times, add 3.5L of ethanol to the separated solution for alcohol analysis, add 1L of ether and 1L of acetone to wash the precipitate, and vacuum freeze-dry the precipitate to obtain mixed polysaccharides (RPs) 159g.

[0028] Classification process: Diethylaminoethyl cellulose is used as a filler, the mass ratio of diethylaminoethyl cellulose to mixed polysaccharides (RPs) is 12:1, and the flow rate is 1.2ml / ...

Embodiment 3

[0031] Rough extraction process: wash 1 kg of Rosa roxa raw material, dry at 50°C for 48 hours, crush, pass through a 60-mesh sieve, add 2L of petroleum ether, reflux at 60-65°C for 2 hours, cool to room temperature, add a weight concentration of 80 % ethanol 1.5L, stand for 3h, evaporate the solvent, add the product to 10L of water, add 200mg of proteinase K, incubate at 37°C for 2h, heat up to 90-95°C, reflux for 4h, cool to room temperature, filter, and the filtrate is heated at 50°C °C, concentrated to 1L under the pressure of -1.9Mpa.

[0032] Deproteinization process: deproteinize 1L of the concentrated solution twice by Sevage method, add 3.5L of ethanol to the separated solution for alcohol analysis, add 1L of ether and 1L of acetone to wash the precipitate, and vacuum freeze-dry the precipitate to obtain mixed polysaccharides (RPs) 183g.

[0033] Classification process: Diethylaminoethyl cellulose is used as filler, the mass ratio of diethylaminoethyl cellulose to mi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap