Method and device for the on-line measuring roundness level of high-precision roller grinder and roller shape error

A technology of roll grinding machine and measuring device, which is applied in the direction of grinding machines, parts of grinding machine tools, and machine tools designed for grinding the rotating surface of workpieces, etc., to achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

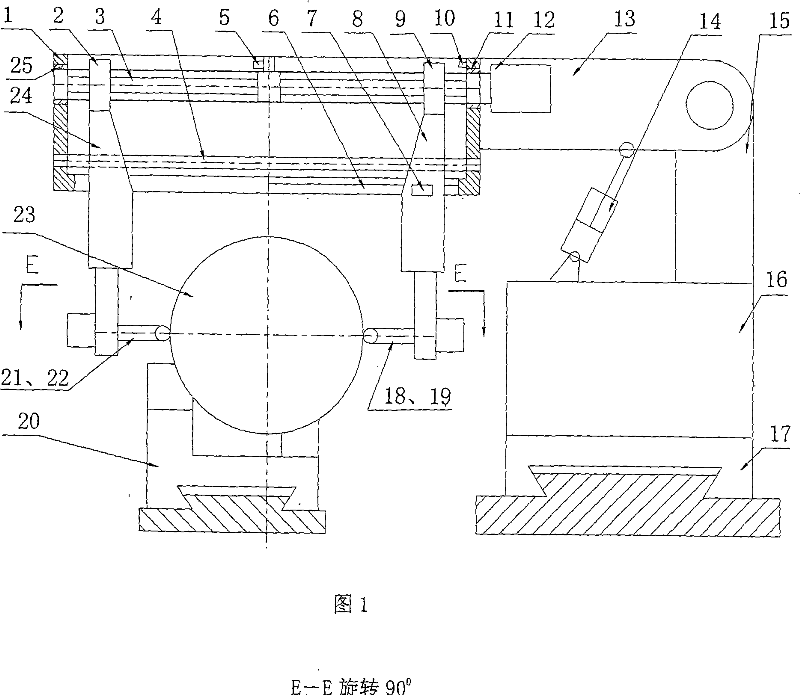

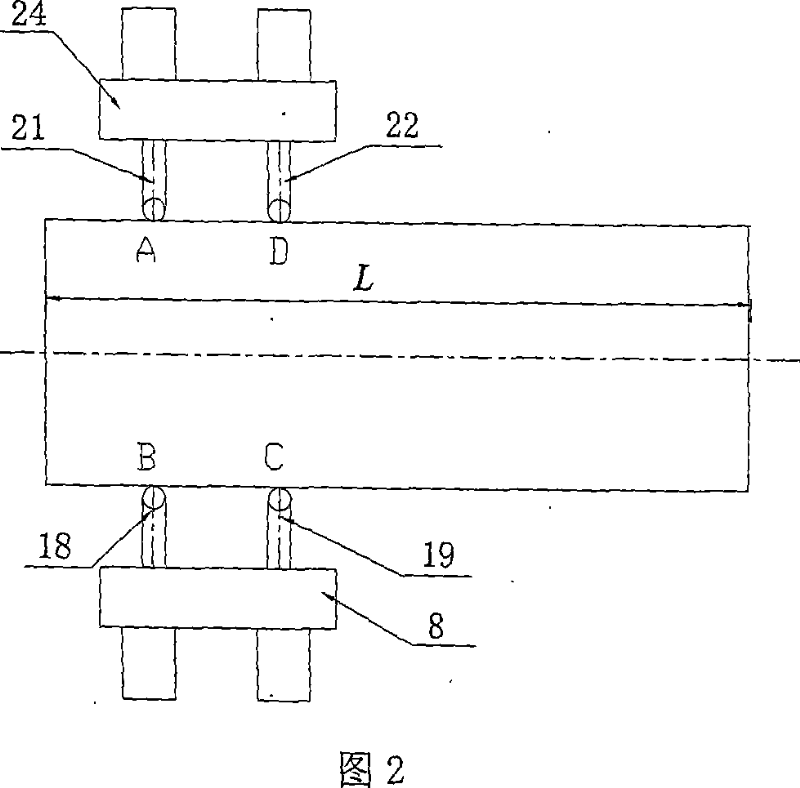

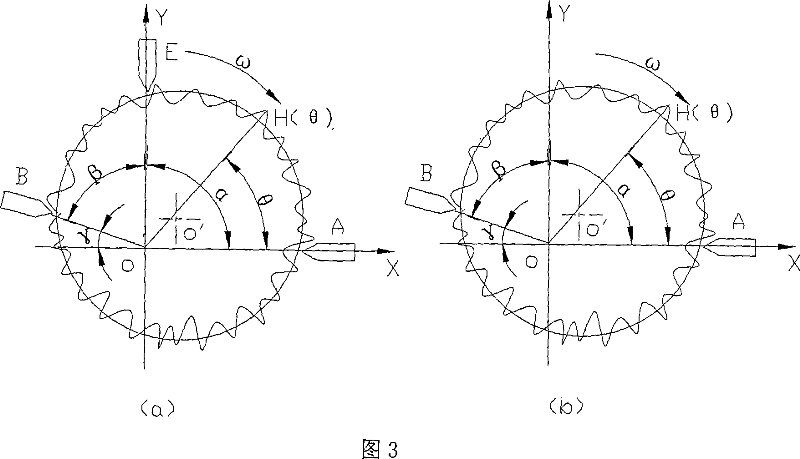

[0091]Referring to Fig. 1, the high-precision roll grinder roll roundness and roll shape error online measuring device includes the roll (23) installed on the roll center frame (20), the grinding wheel frame (16) installed on the carriage (17) And measuring frame (1), it is characterized in that: (a) described measuring frame (1) is fixedly connected a crossbeam (13), and crossbeam (13) and a pillar (15) that is fixed on the grinding wheel frame (16) ) is hinged; the oil cylinder of a hydraulic lift regulator (14) is hinged with the grinding wheel frame (16), and the outer end of its piston rod is hinged with the beam (13); (b) the measuring frame (1) passes through Two high-precision bearings (25, 11) support a left-handed high-precision ball screw (3), and the ball screw (3) is screwed with a left-handed ball nut (2) and a right-handed ball nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com