Computer-direct-control type printing graph plotter by using viscos colorant

A computer and master computer technology, applied in the field of plotters, can solve the problems of no sticky printing material, high power consumption, environmental pollution, etc., and achieve the effect of high accuracy, low cost, and uniform coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

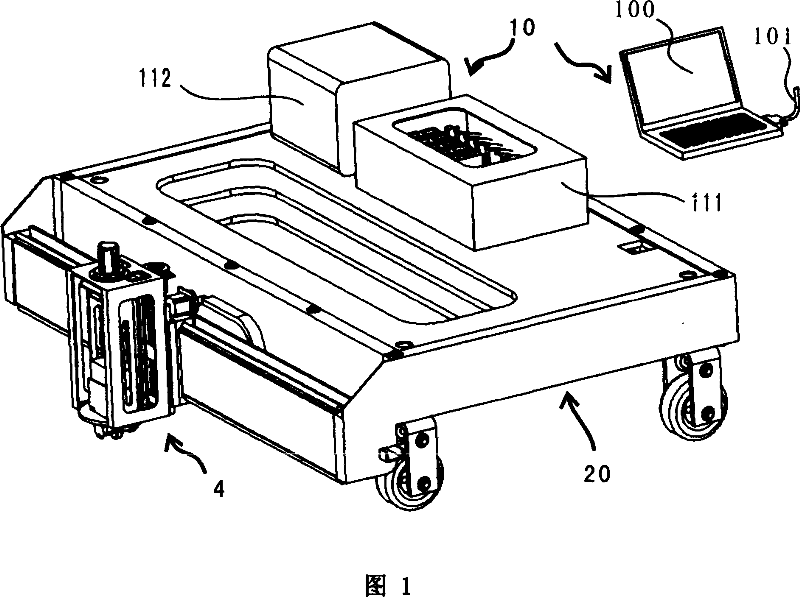

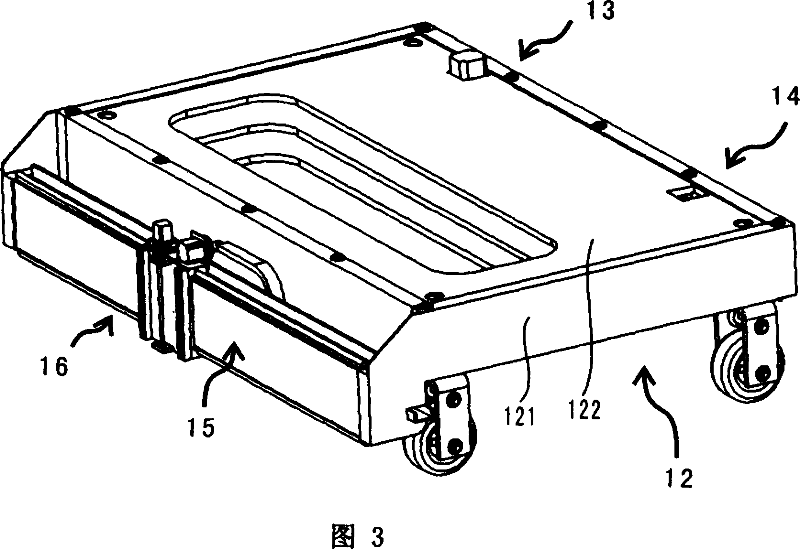

[0049] As shown in Fig. 1, what the present invention provides is a computer direct-controlled transfer printing plotter that can use viscous color paste, mainly including a computer and a control circuit (10), a multi-directional translational movement mechanism (2), a transfer printer Head mechanism (4), wide stroke color paste box mechanism (28), fine stroke color paste box mechanism (33).

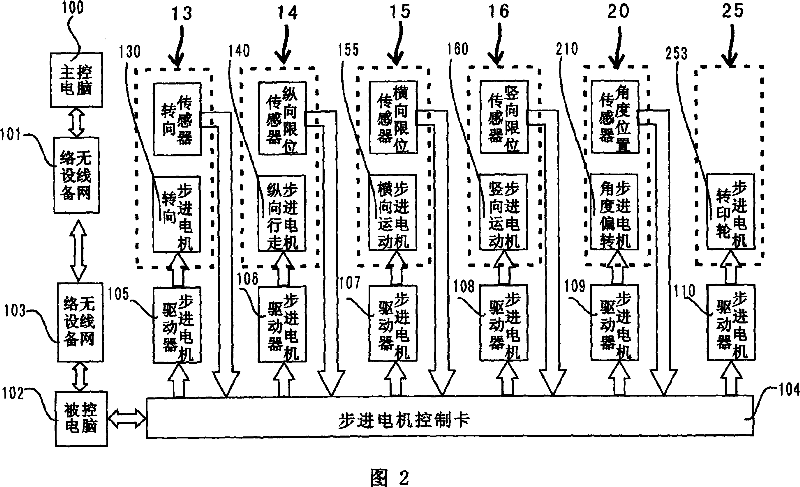

[0050] As shown in Fig. 1 and Fig. 2, the computer and the control circuit 10 are mainly composed of a master computer 100, a master computer wireless network device 101, a controlled computer 102, a controlled computer wireless network device 103, a stepping motor motion control card 104, Stepping motor drivers 105, 106, 107, 108, 109, 110, chassis 111, power supply 112 are composed; wherein the main control computer 100 is connected to the wireless network device 101, and the controlled computer 102 is connected to the wireless network device 103 and the stepping motor motion control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com