Technique process for coal flow fractionation and moisture adjustment

A technology of airflow classification and process method, which is applied in the petroleum industry, coke oven and other directions, and can solve the problems of many equipment, complex process procedures, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

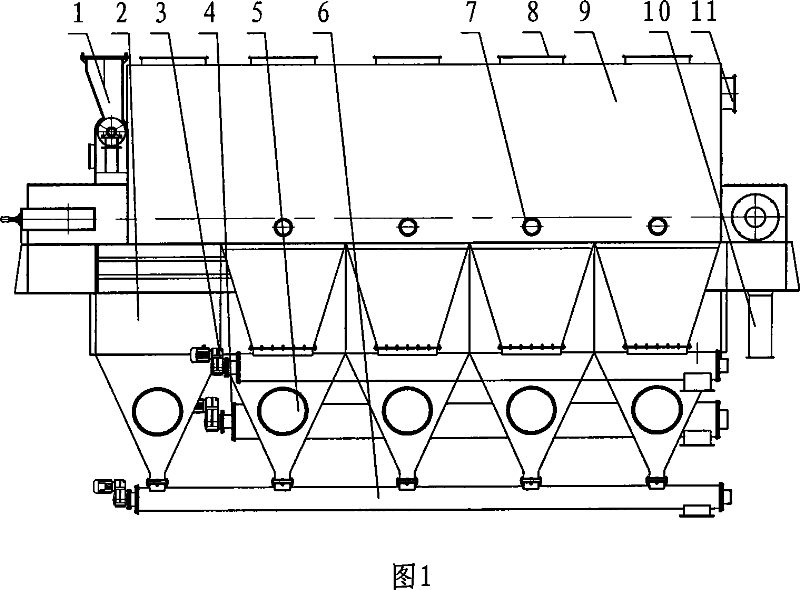

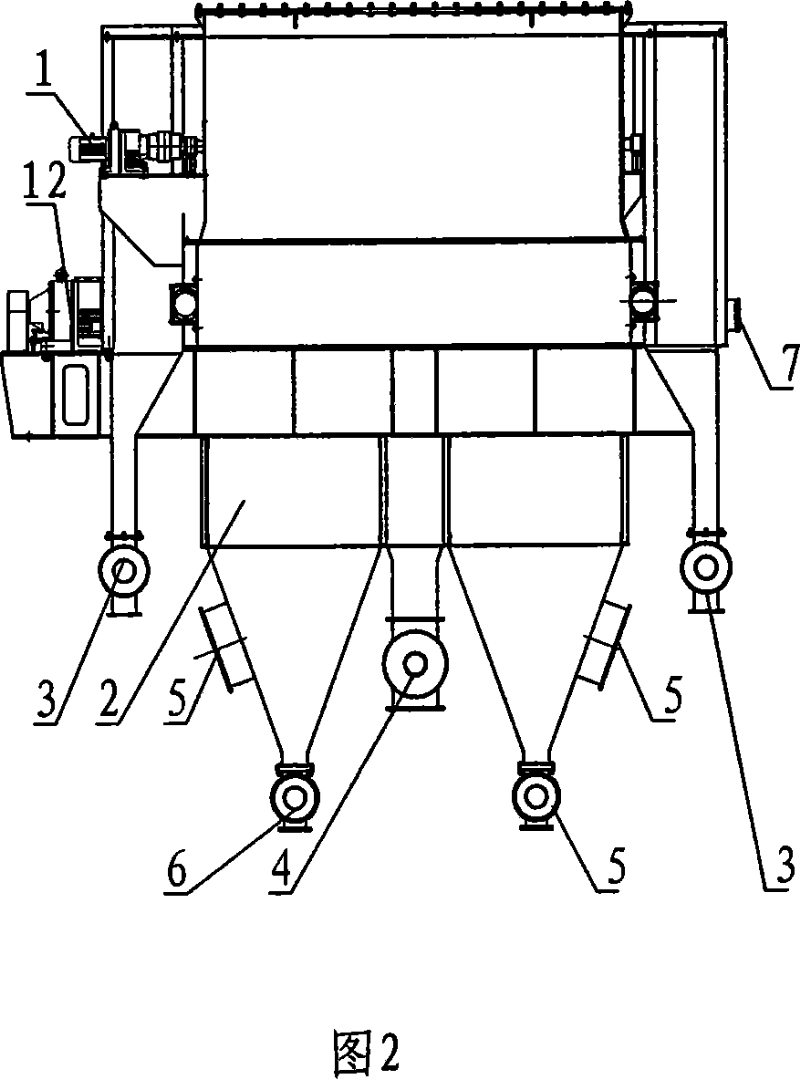

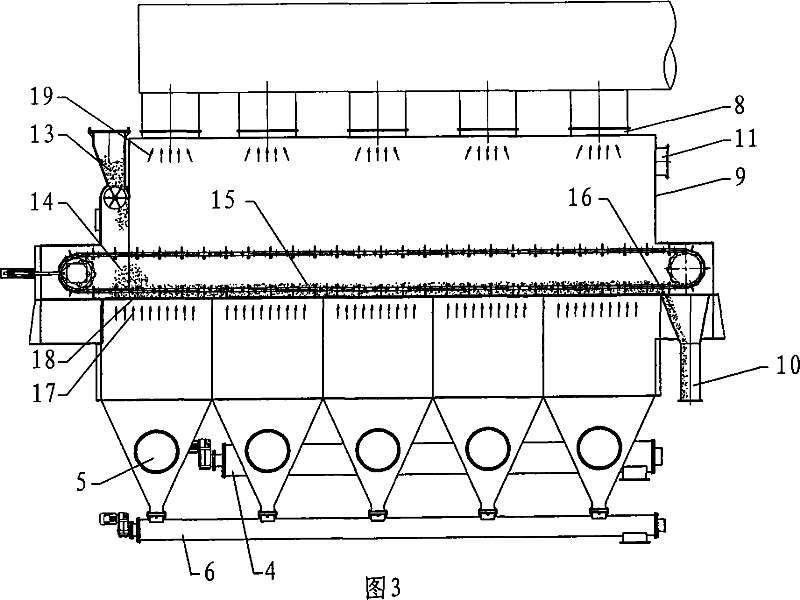

[0019] The method of the present invention is a set of coal pretreatment process that uses coke oven flue gas as a heat source and power source to dry and classify and crush coal, and realizes the three functions of "drying, classifying and preheating" for coking mixed coal. , this process successfully utilizes the mature solid fluidization drying theory to reduce the moisture content of the coke oven coking coal from 8 to 10% to 6%, and at the same time realize the classification of coal, especially the structure of moving partitions , which is equivalent to dividing a large fluidized bed into several movable small fluidized beds, thereby improving the fluidization effect of the raw coal in the equipment and ensuring the drying effect and grading effect of the raw coal. The method of the present invention will be described in detail below in conjunction with the structure of the moving partition fluidized bed.

[0020] The movable partition fluidized bed includes a fluidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com