Heat exchanger for heat pump

A technology of heat exchangers and heat pumps, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve problems such as unavailable evaporators, increased air flow resistance, increased heat transfer resistance, etc., to achieve Disturb the temperature boundary layer, enhance the mixing of airflow, and enhance the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

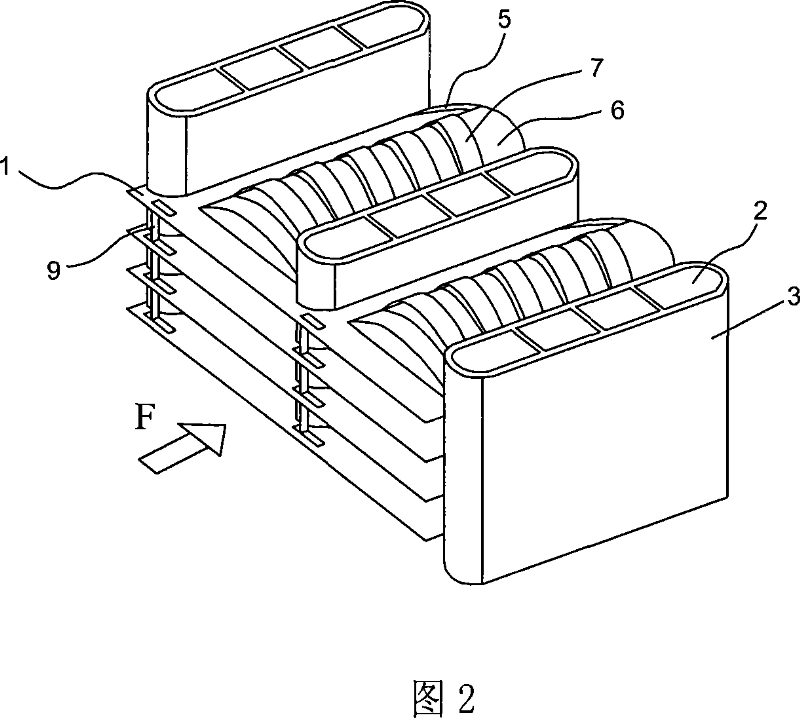

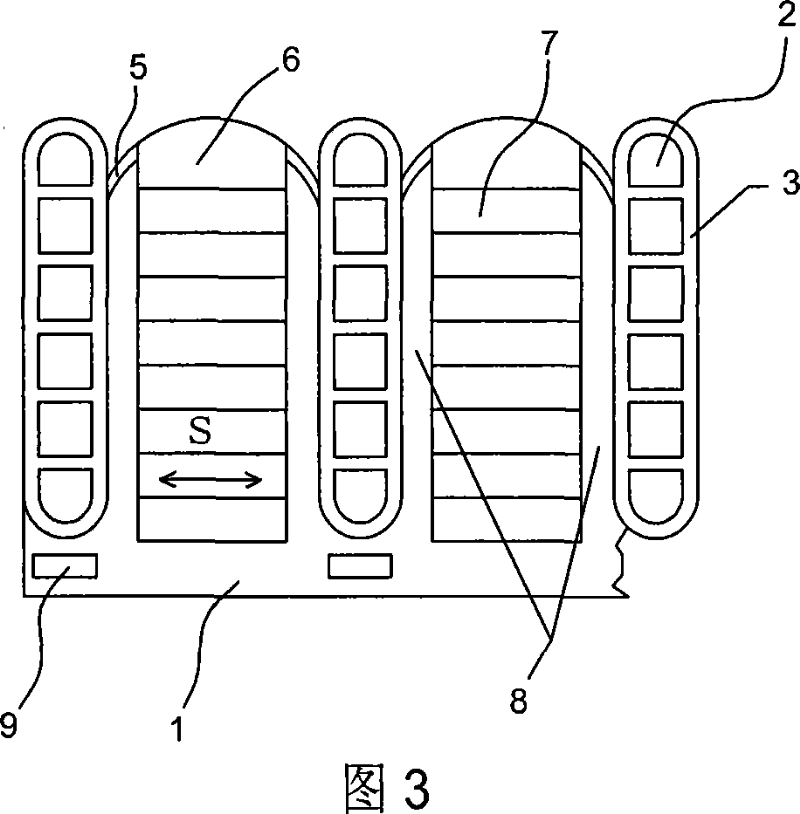

[0032] Please refer to Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6 and Fig. 7 in combination. A deflector 8 is provided, and the deflector 8 is connected to the end of each bridge, so that the condensed water or defrosting water formed above the arched bridge can flow to both sides along the surface of the bridge under the action of surface tension. Convergence at the deflectors on both sides of the cell heat sink. The front edge of the deflector 8 is provided with a water-blocking emboss 5, and the front end of the deflector 8 is also provided with a drain 6 for discharging condensed water or defrosting water downwards. The drain 6 is arranged obliquely near the resistance An opening of the water embossment 5 . As shown in Figures 4, 5, and 6, the drain sheet 6 is a downwardly inclined concave sheet with arc-shaped edges. The unit cooling fin has a distance between the fins and the fixed fins 9 , and the height of the fins and the fixed fins 9 is greater than the height of any a...

Embodiment 2

[0041] As shown in FIG. 8 , the difference between this embodiment and Embodiment 1 is that in this embodiment, the arched bridges of the unit cooling fins consist of multiple sets of two upwardly interlaced arched bridges 7 a and 7 b.

Embodiment 3

[0043] As shown in Figure 9 and Figure 10, the difference between this embodiment and Embodiment 1 is that in this embodiment, the front ends of the two guide fins 8 of each unit cooling fin are connected into one body through a flat sheet, and the water blocking embossed lines 5 It is arranged at the front edge of the flat sheet and the two guide sheets 8 , and the discharge sheet 6 is obliquely arranged near an opening of the water blocking rib 5 . The condensed water above the arched bridge plate 7 flows to the guide plate 8 under the action of surface tension and gravity, and cannot fly out of the heat exchanger when encountering the water blocking ribs 5, but is drained downward by the drain plate 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com