Semiconductor device and method of manufacturing the same

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as difficulty in realizing the miniaturization of electrode pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

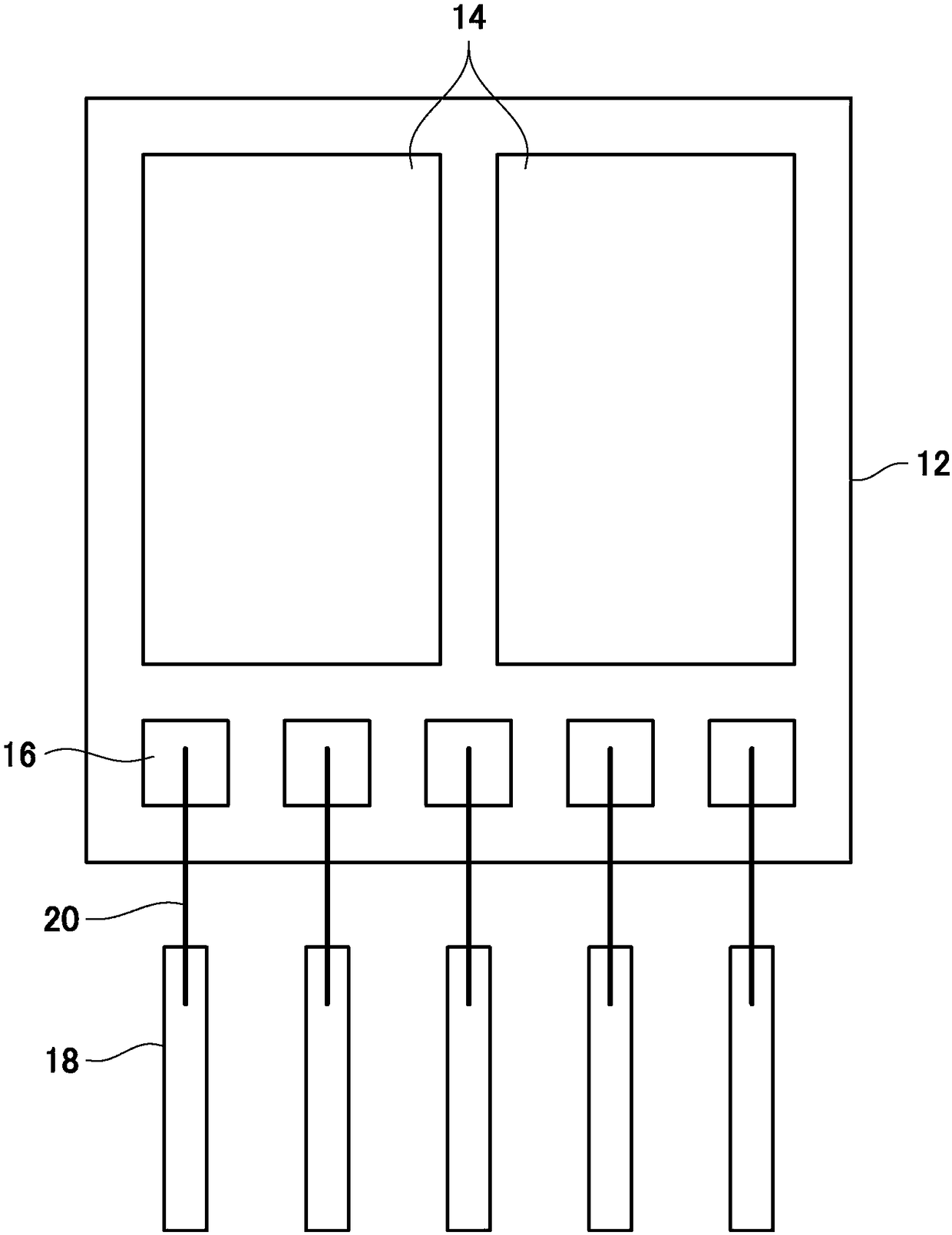

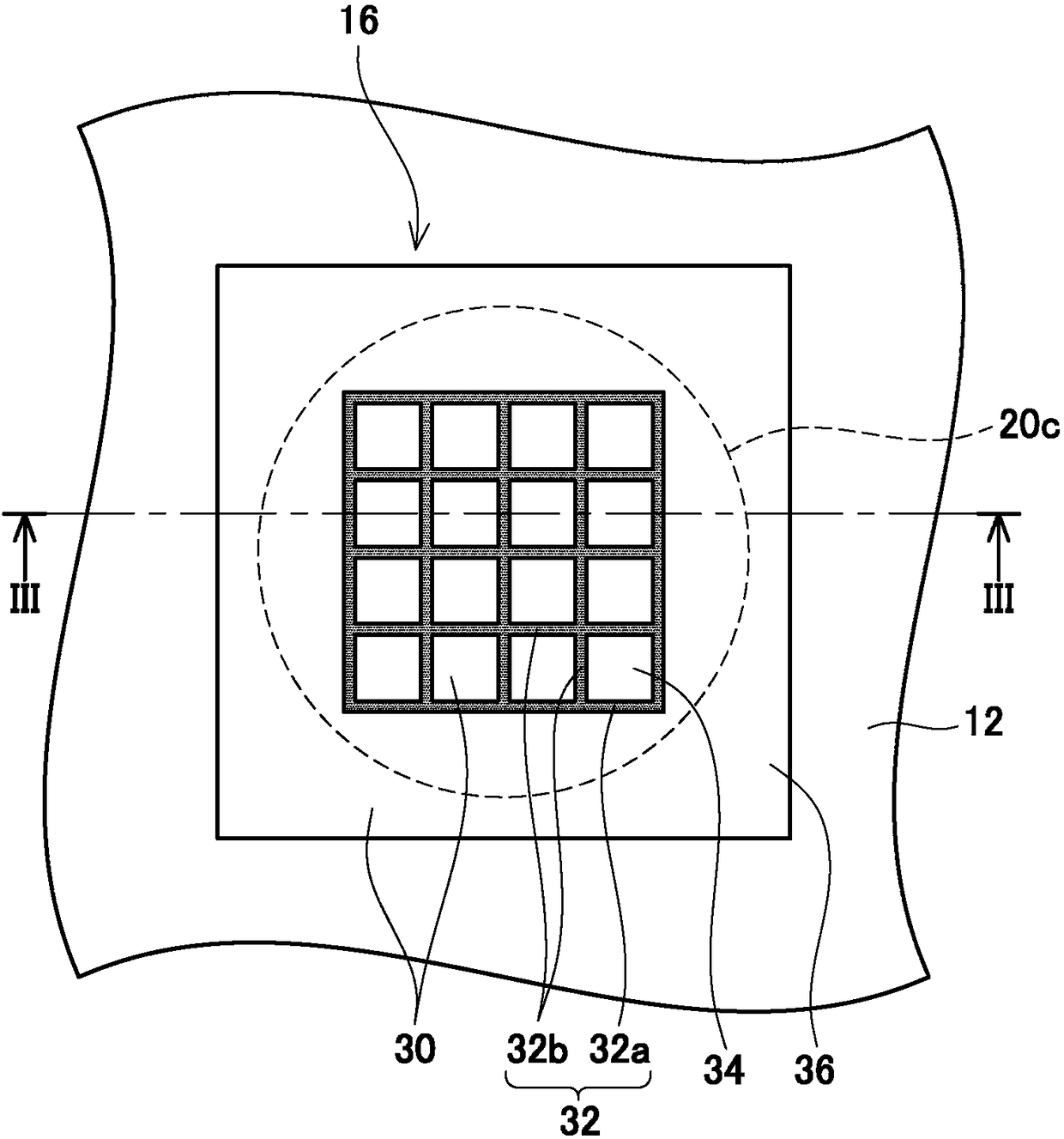

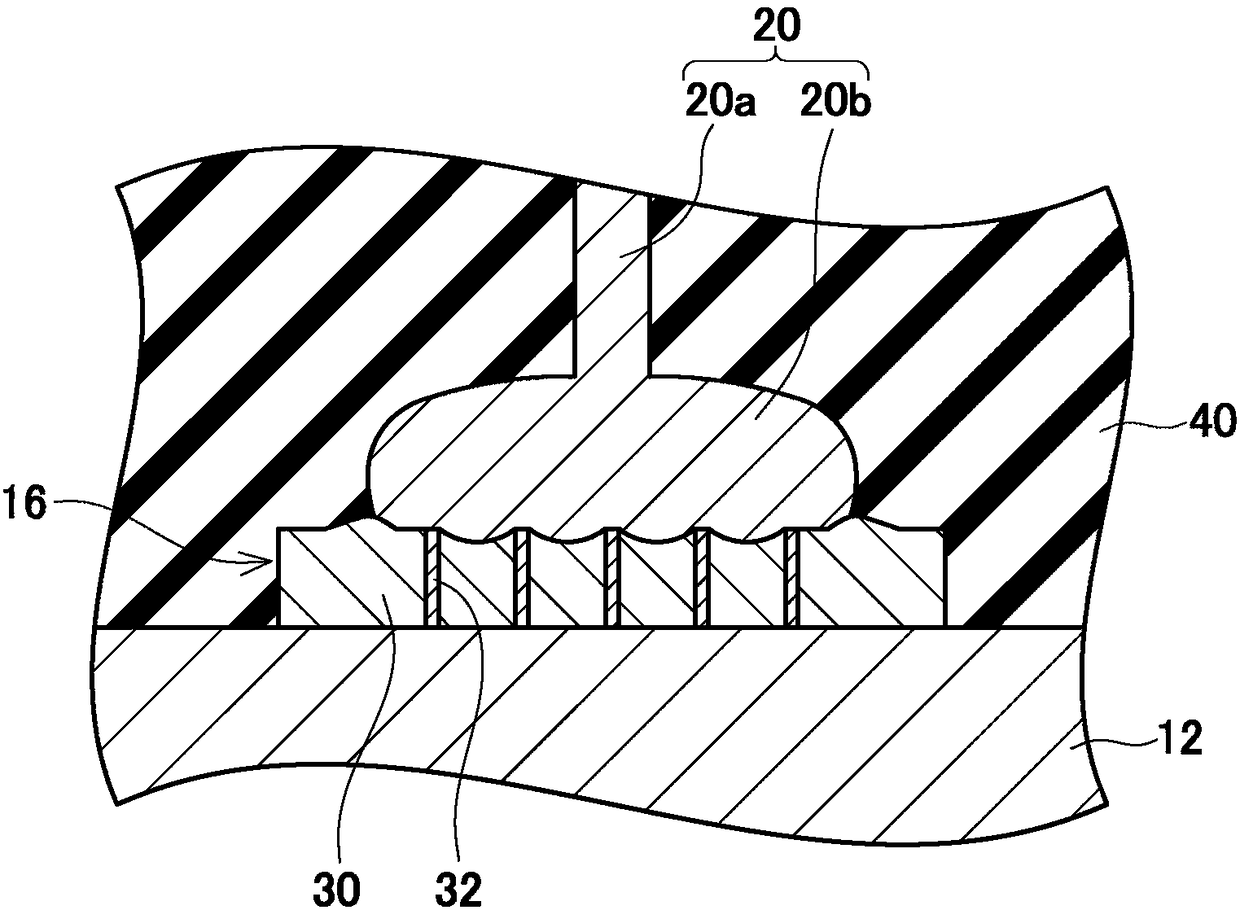

[0023] figure 1 The upper surface of the semiconductor device is shown. The semiconductor device has a semiconductor substrate 12 . The semiconductor substrate 12 is composed of a semiconductor mainly composed of Si (silicon). In addition, the semiconductor substrate 12 may be made of a wide bandgap semiconductor mainly composed of SiC (silicon carbide) or GaN (gallium nitride). Main electrodes 14 and signal electrode pads 16 are provided on the upper surface of the semiconductor substrate 12 . The size of each signal electrode pad 16 is smaller than the size of each main electrode 14 . The main electrode 14 is connected to an unillustrated wiring member by solder. A plurality of pins 18 are arranged on the side of the semiconductor substrate 12 . Each signal electrode pad 16 is connected to a corresponding pin 18 through a lead wire 20 . Furthermore, although not shown, a lower electrode is provided on the lower surface of the semiconductor substrate 12 . The lower ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com