Apparatus for preparing Two-sided micropore burr steel belt

A technology for production equipment and burr steel strips, applied in metal processing equipment, perforation tools, electrode manufacturing, etc., can solve the problems of difficult punching of microporous products, low production efficiency, large hole spacing, etc., to improve the packaging capacity and Effects of fixing strength, improving production efficiency, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

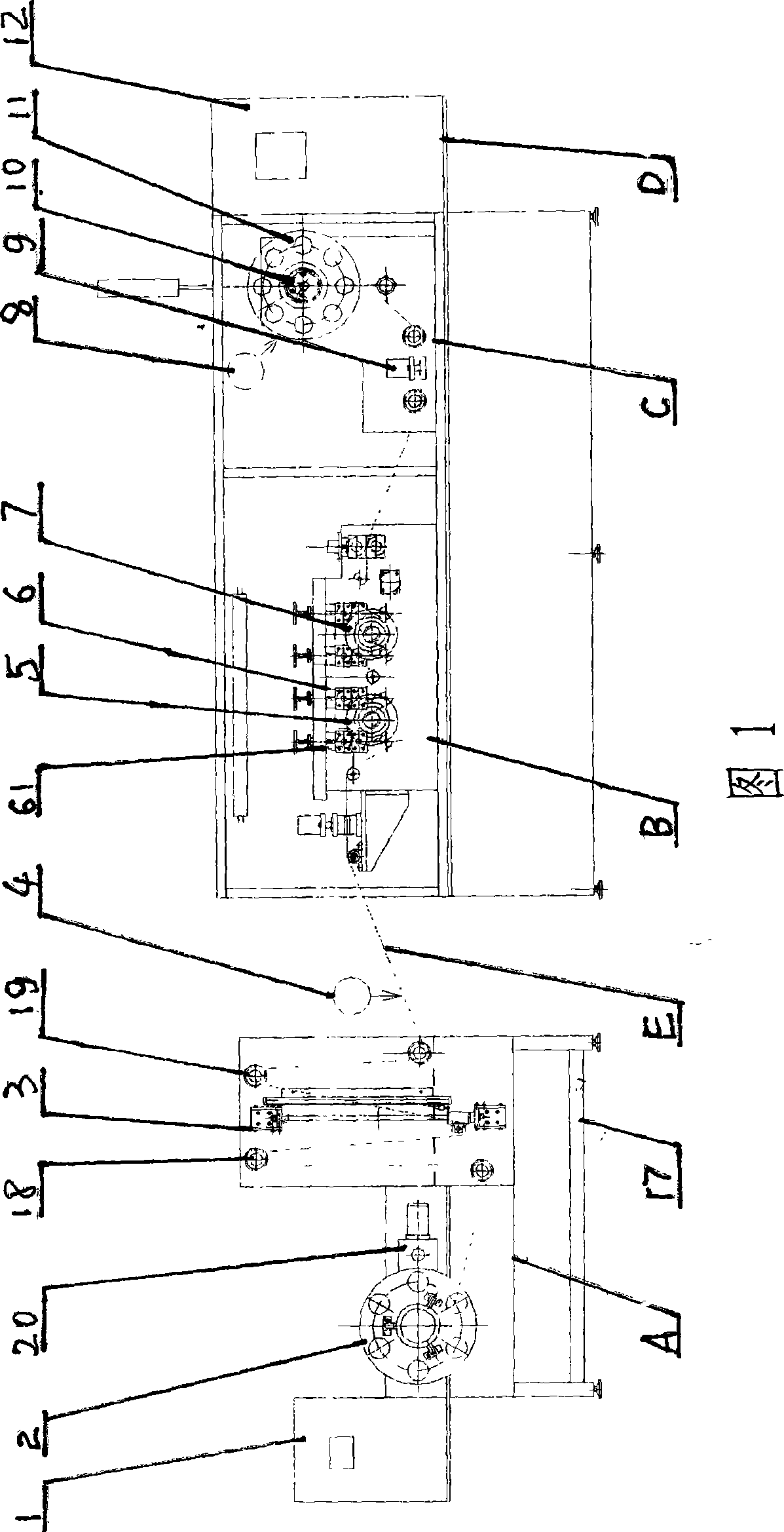

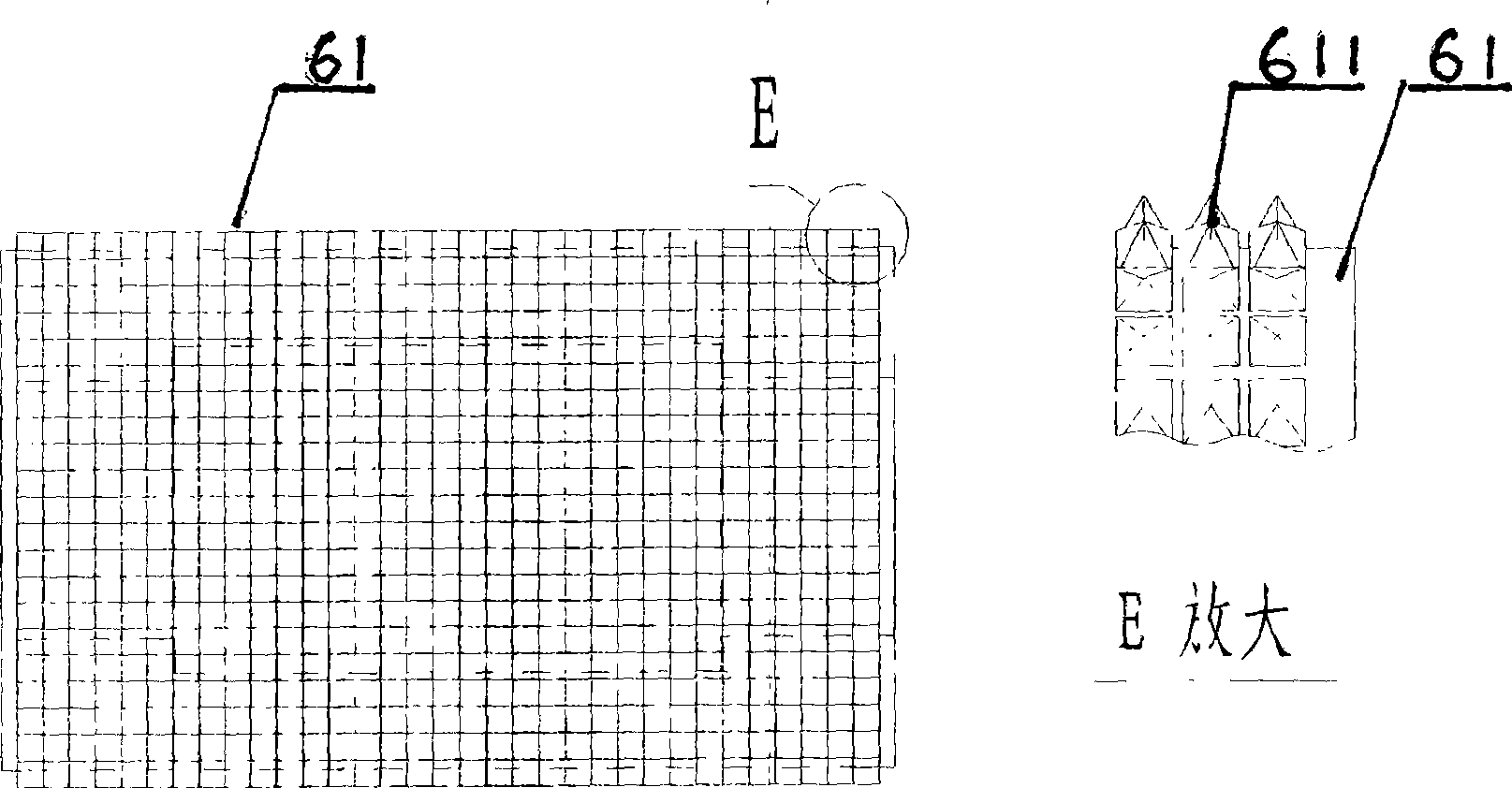

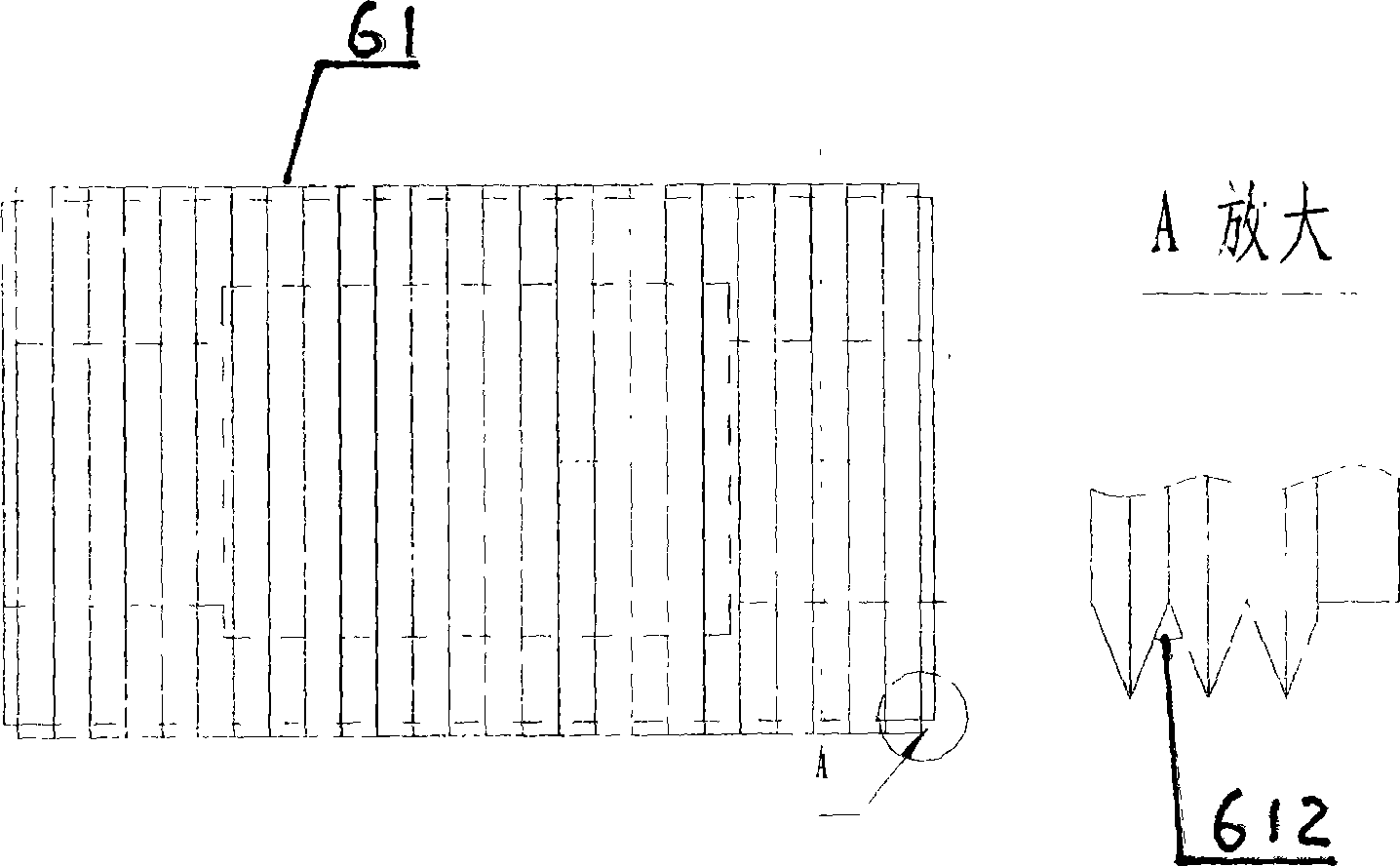

[0026] See Figure 1~ Figure 11 , the present invention provides double-sided microporous burr steel perforation equipment based on the principle of double-wheel pair-roller perforation. and so on. The descriptions are as follows: Automatic belt unwinding system A: This system consists of a belt unwinding frame 2, a constant tension mechanism 3, a broken belt protection mechanism 4, and a mechanical power mechanism 20. The mechanical power mechanism is composed of a motor and a reducer. Frame 2 central shafts are connected, together set up on its frame 17 with belt rack 2, constant tension mechanism 3 is installed on the frame beside this belt rack 2, a group of guide wheels 18 are respectively housed in its front and rear The E support is an M-shaped path, and the electronic ruler elastic stick of the constant tension mechanism 3 is pushed against the upper side of the lower middle of the M-shaped path, and the frequency of the motor of the mechanical power mechanism is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com