Integrated washer

A cleaning machine and an integrated technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cleaning machines such as rust, splashing, and not easy to dry, so as to prolong the service life and structure Good compactness and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

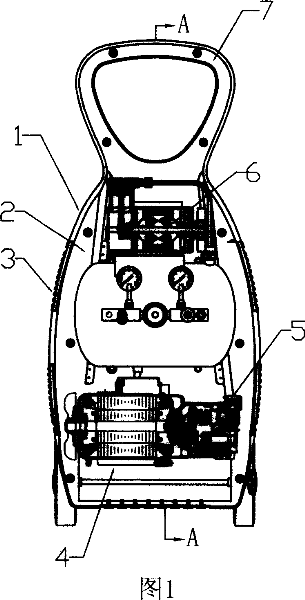

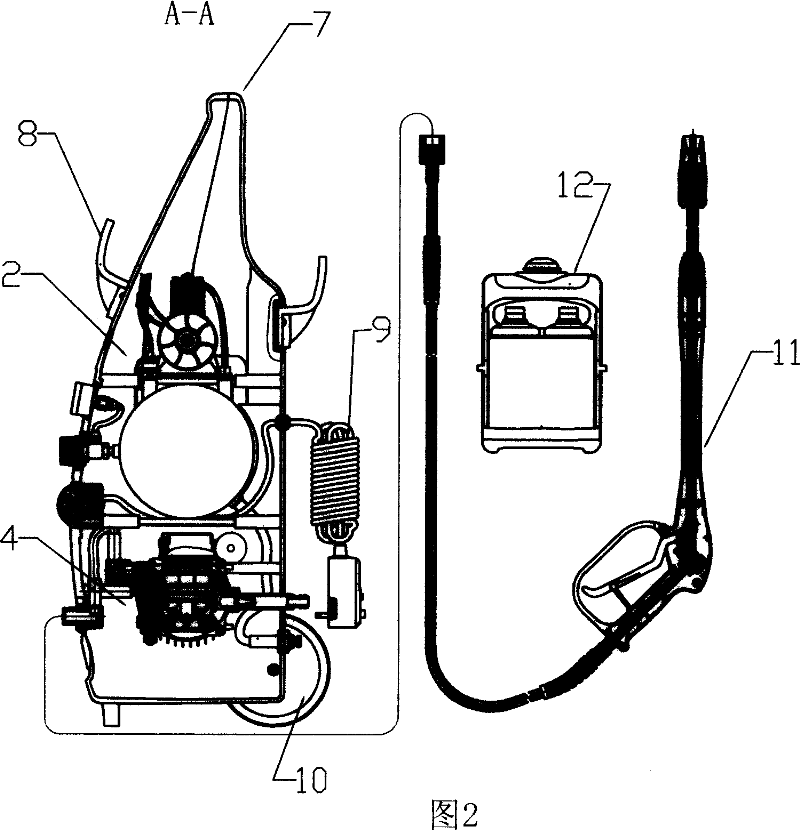

[0020] As can be seen from Fig. 1 and Fig. 2, the integrated washing machine of the present invention is mainly composed of a washing machine assembly 4 and an air compressor assembly 2, both of which are installed and fixed in a closed housing 1, wherein the air compressor The assembly 2 is fixed above the inside of the casing 1 , and the washing machine assembly 4 is located below the air compressor assembly 2 in the casing 1 .

[0021] The above-mentioned casing 1 is composed of two sheet-shaped monomers fastened together. Two castors 10 are arranged below the casing 1, a traction handle 7 is arranged above, and a number of shutters 3 communicating with the outside are arranged in the middle. The traction handle 7 is integrally formed with the housing 1 and is formed by a hole provided on the upper part of the housing 1 .

[0022] The air compressor assembly 2 has a motor 6, which is a series motor, and the cleaning machine assembly 4 has a motor 5, which is an induction mo...

Embodiment 2

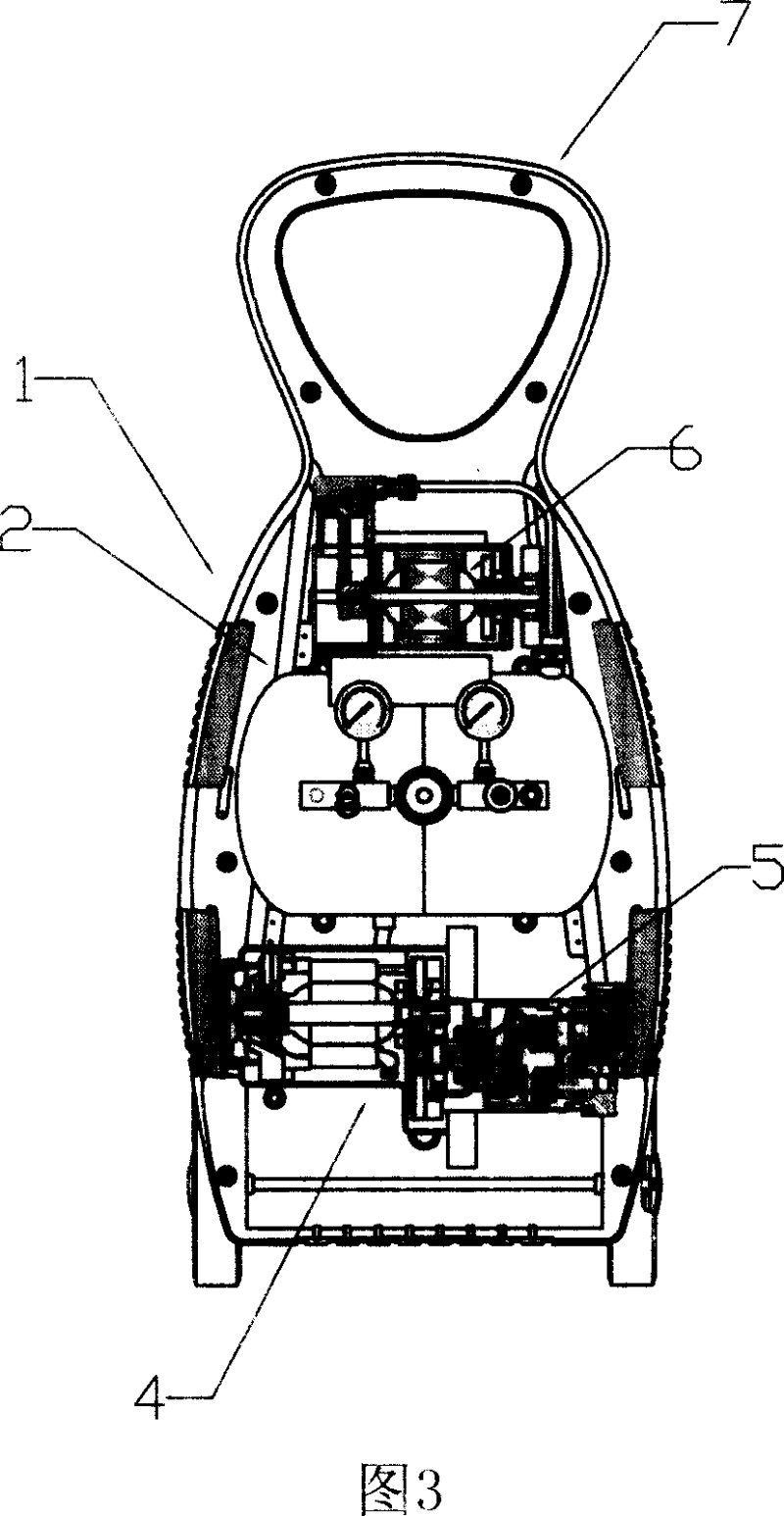

[0025] As shown in Fig. 3, in this embodiment, other structures of the integrated cleaning machine of the present invention are the same as those in the embodiment, except that the motor 5 in the cleaning machine assembly 4 is a series motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com