On-line detection Method and apparatus for chain cloth performance

A detection method and detection device technology, which are applied in measurement devices, instruments, analysis of suspensions and porous materials, etc., can solve the problem of inability to quantitatively detect the liquid content of filter cloth, the air permeability of filter cloth cannot be quantitatively determined, and the air permeability is difficult to determine and correct. Value and other issues, to achieve the effect of clear test results, strong production guidance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

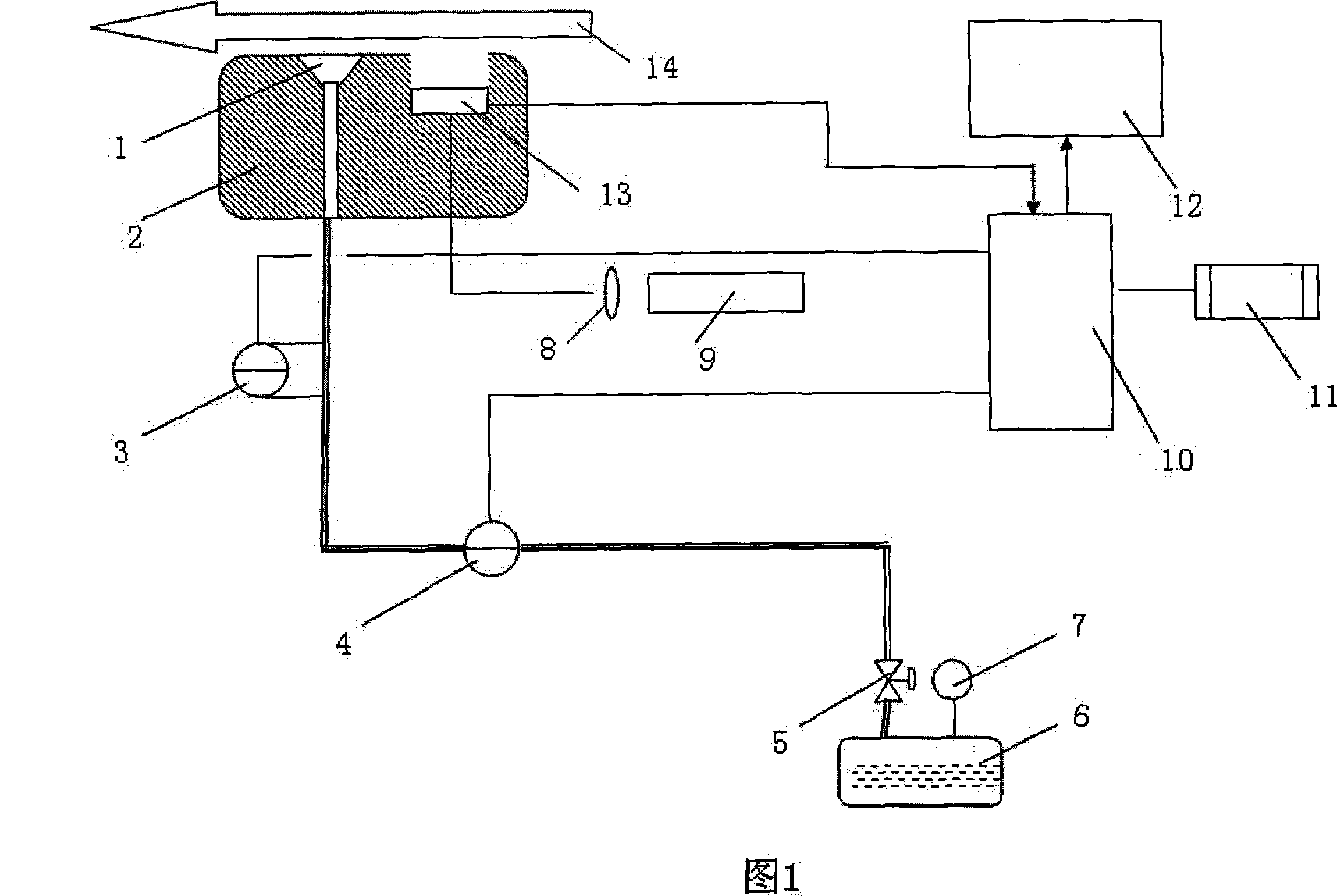

[0024] The liquid meter of the detection device in this embodiment is an infrared liquid meter, and the liquid content detection method adopts an infrared detection method. Referring to FIG. 1 , the liquid meter of the detection device mainly includes an infrared liquid meter including an infrared light source 9 and an optical filter 8 , and an infrared liquid detection head 13 is selected as a liquid detection head. The nozzle 1 and the infrared liquid detection head 13 are installed in the probe 2 . The filter wavelength of the embodiment optical filter 8 is 1.4-1.9 microns; A certain amount of liquid and compressed air are housed in the pressure tank 6, and the pressure gauge 7 showing the compressed air pressure is installed on the pressure tank 6; Pressure valve 5; Power supply selects portable power supply 11 for use. After the nozzle 1 is connected to the pressure sensor 3 and the flow sensor 4, it is connected to the pressure tank 6 through the manual pressure regulat...

Embodiment 2

[0037] The liquid meter of the detection device in this embodiment is a resistive liquid meter, and the liquid content detection method adopts a resistance detection method.

[0038] As the liquid content of a substance changes, its electrical resistance changes accordingly. For example, when the liquid content of wheat is 13%, the resistance value is 7 times that when the liquid content is 14%, and is 50 times that when the liquid content is 15%. A small change in the liquid content of the substance can cause a significant difference in the resistance value of the substance, which is the principle of the resistance method to determine the liquid content of the substance. The resistance method to measure the liquid content is to detect the resistance value of the filter cloth and then convert it into liquid content. This liquid content detection method has the advantages of fast and simple.

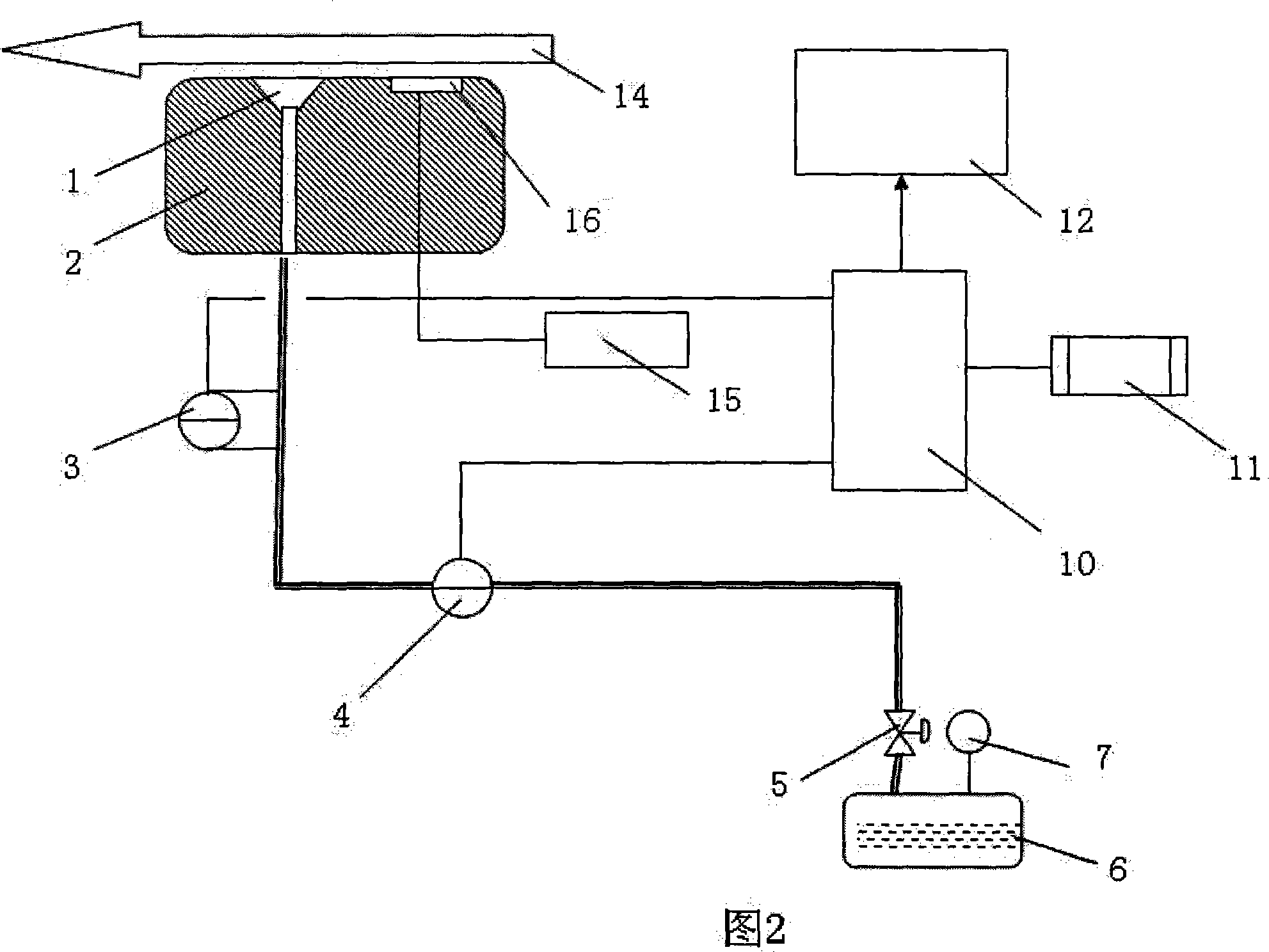

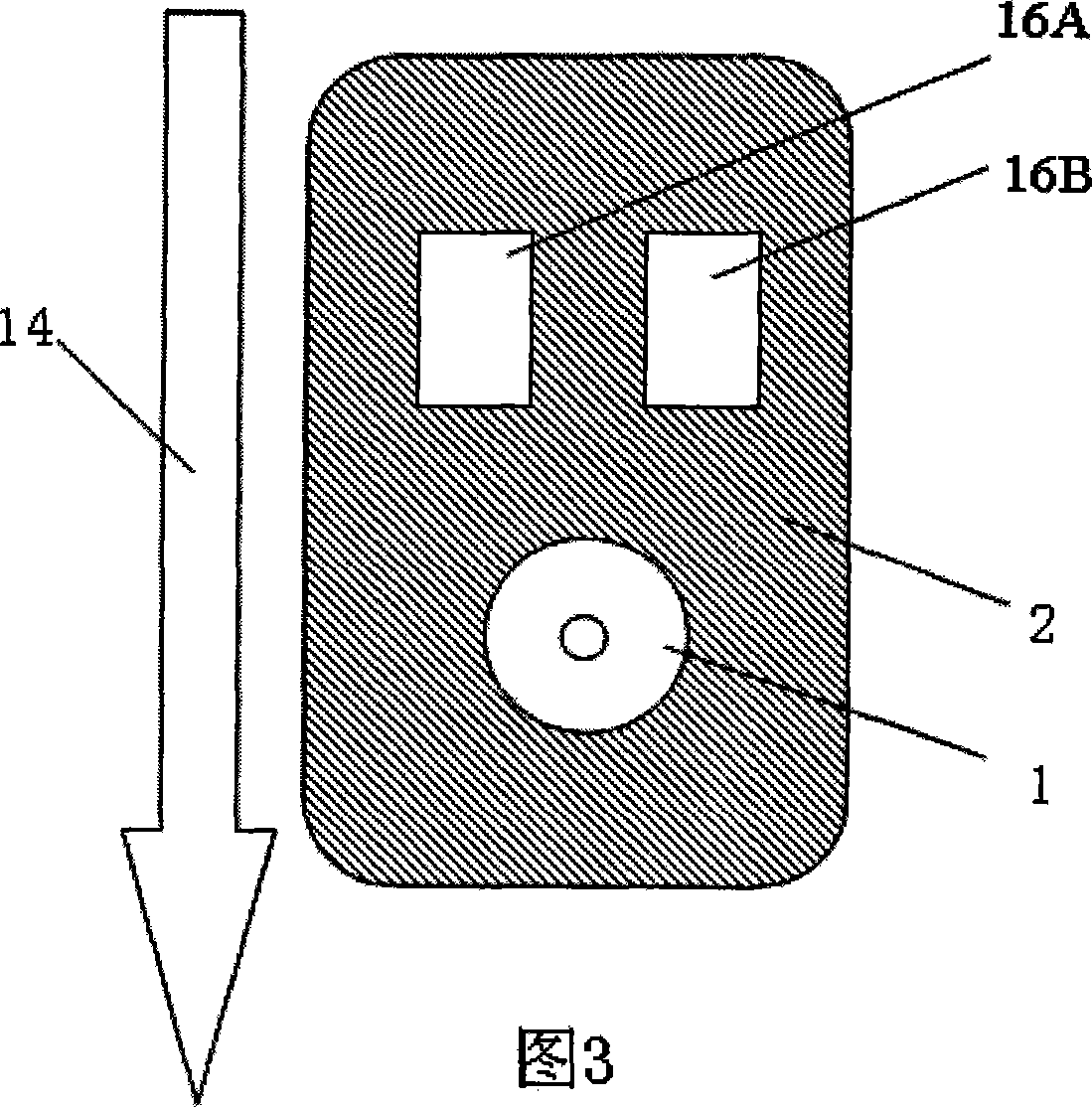

[0039] Referring to Fig. 2 and Fig. 3, the liquid meter of the detection device is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com