Head driving mechanism for flat knitting machine

A driving mechanism and technology of flat knitting machine, applied in knitting, weft knitting, textile and paper making, etc., can solve the problems of large volume, motor burnout, accidents, etc., to reduce the overall volume, save energy, and use safe Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

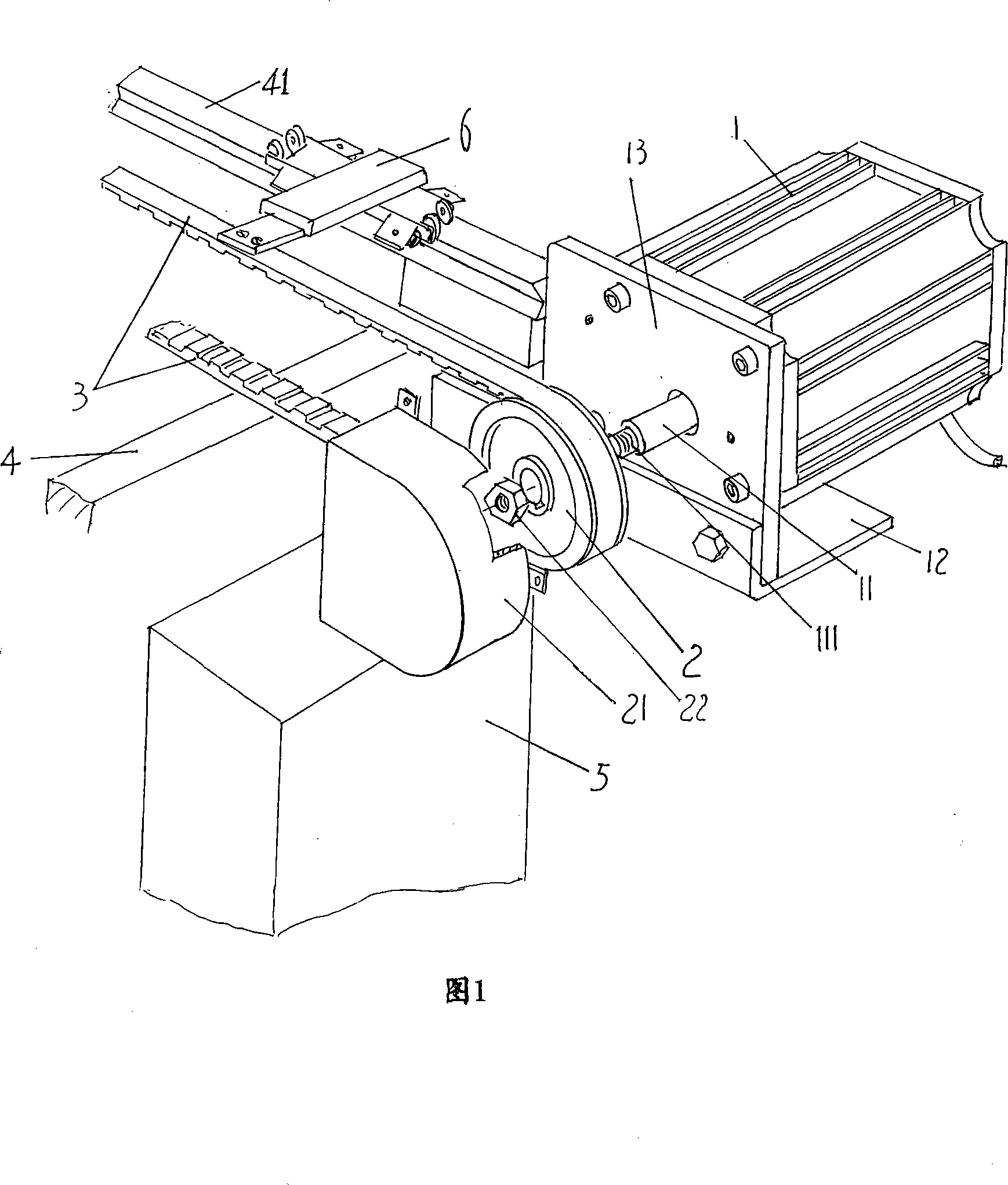

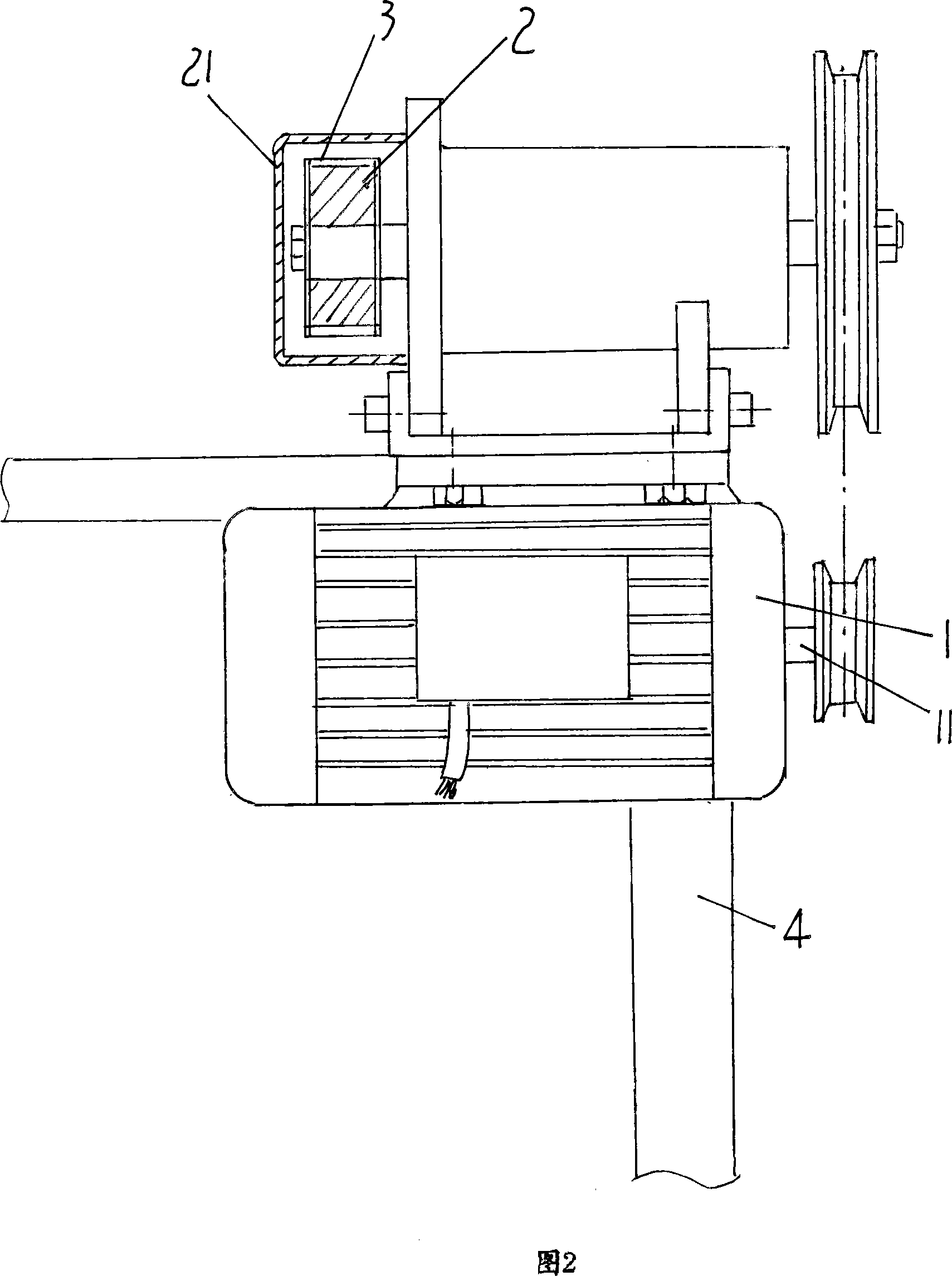

[0009] Please refer to Fig. 1, at an end of frame 4 promptly keep with the electric control box 5 same end installation motor 1 with the left end of current figure position, this motor 1 is installed on frame 4 by motor support 12. For the motor 1, a DC brushless motor should be used. This DC brushless motor can be obtained from market channels, for example, a DZGSWH-1 DC brushless motor produced and sold by Changshu Electric Machinery Factory Co., Ltd., Jiangsu Province, China. The end of the power output shaft 11 of the motor 1 is processed with a matching thread 111. After the timing pulley 2 is sleeved on the power output shaft 11, the timing pulley limiting nut 22 is screwed onto the matching thread 111. It is also possible to connect the synchronous pulley 2 and the power take-off shaft 11 with a flat key for fixed connection. A shield 21 is arranged outside the synchronous pulley 2, and the shield 21 is fixed with the motor holder 13 by screws, and the motor holder 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com