Low trigger voltage silicon control rectifier and its circuit

A technology of silicon controlled rectifier and low trigger voltage, which is applied in circuits, electric solid-state devices, electrical components, etc., and can solve problems such as inability to use power protection and inability to eliminate the locked state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

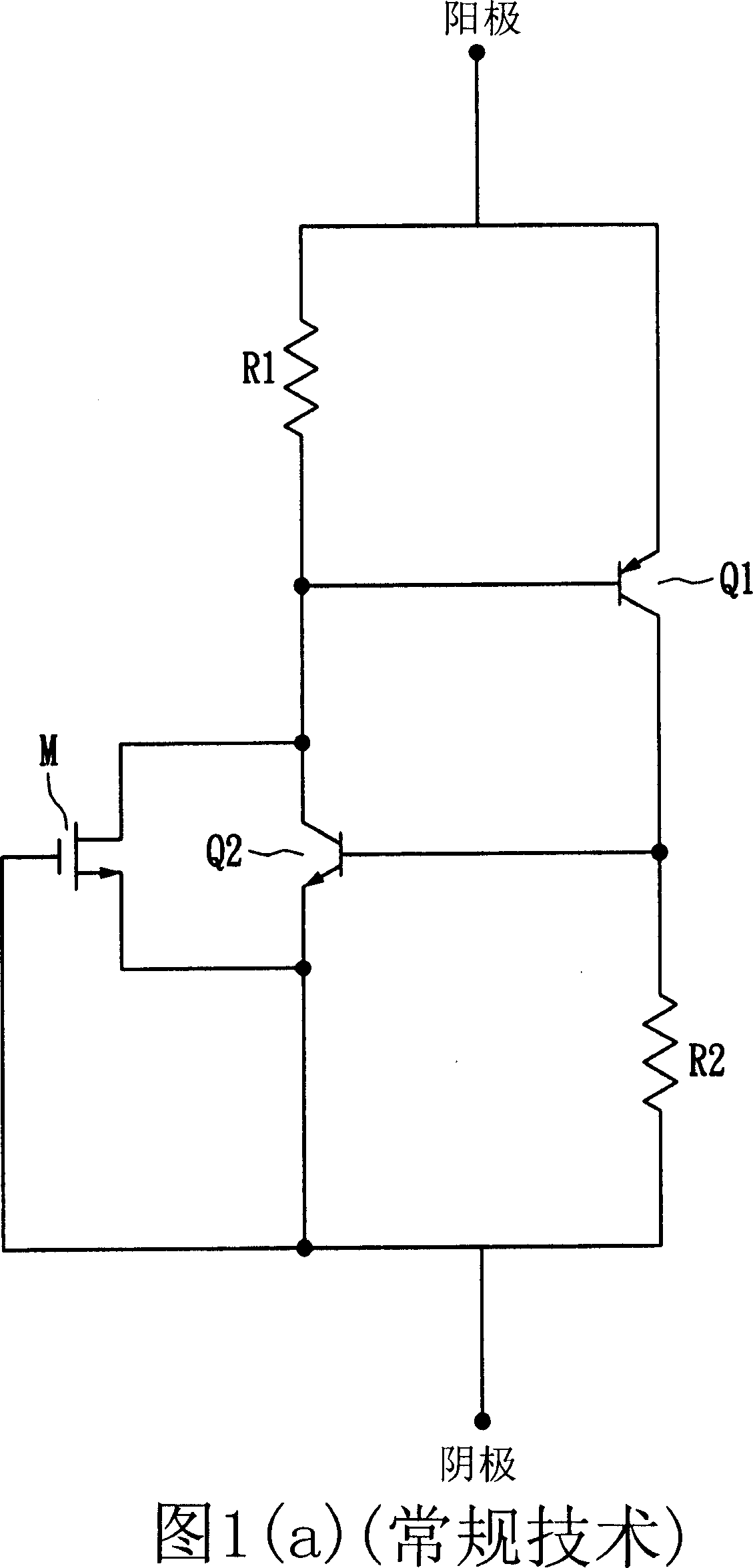

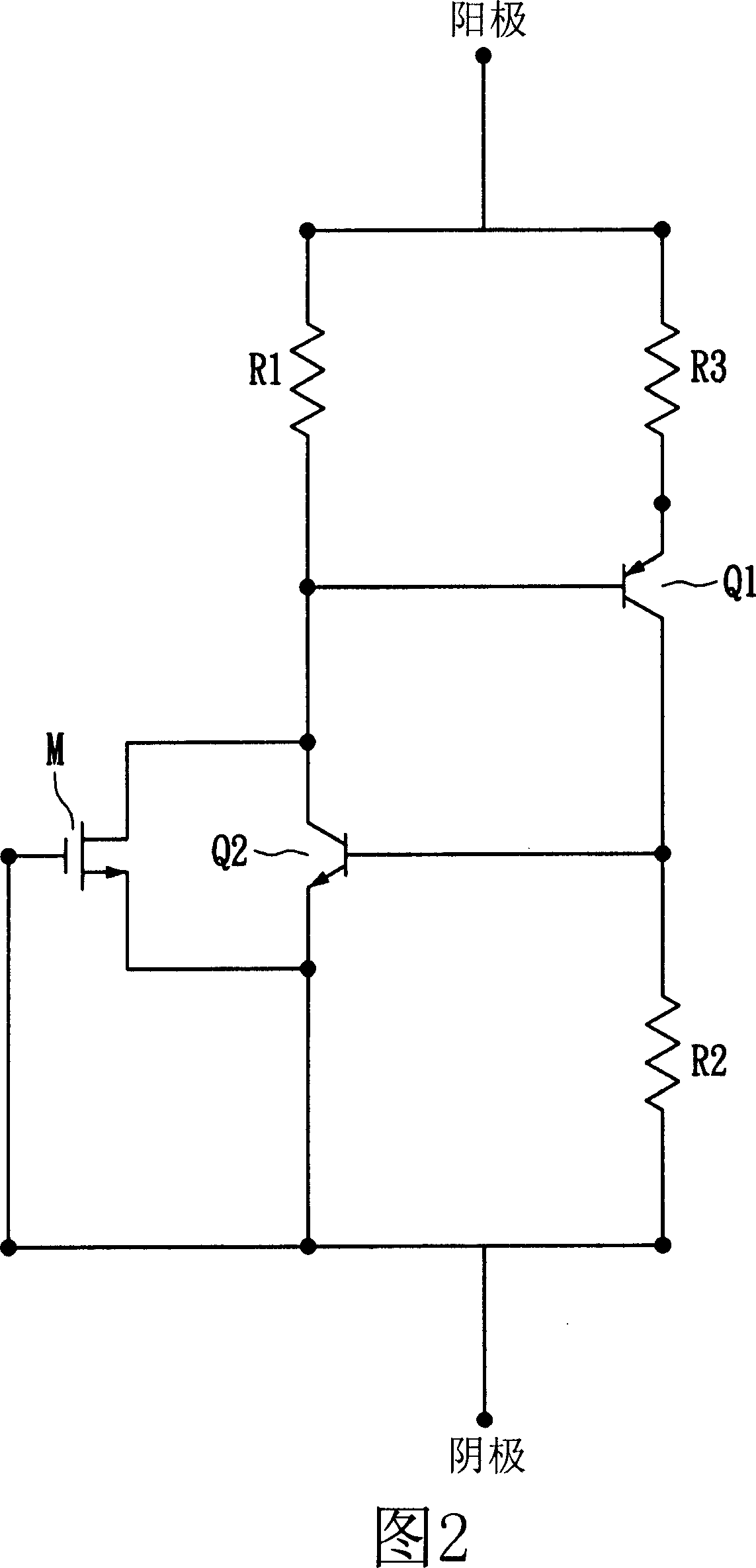

[0022] FIG. 2 is an equivalent circuit of the low trigger voltage silicon-controlled rectifier of the present invention, which adds a resistor R3 between the anode and the emitter of the parasitic bicarrier PNP transistor Q1 in the circuit of FIG. 1(a). Its operating principle is as follows. Because the breakdown voltage of the NMOS transistor M is lower than the breakdown voltage of the parasitic bicarrier NPN transistor Q2, when an ESD occurs, first the NMOS transistor M is turned on, and the current conduction acting on the NMOS transistor M will make a and The parasitic bipolar NPN transistor Q2 coupled with the resistor R2 is also turned on, and the current conduction of the parasitic bipolar NPN transistor Q2 will cause the parasitic bipolar PNP transistor Q1 to turn on. The current acting on the parasitic bipolar PNP transistor Q1 will accelerate the current conduction of the parasitic bipolar NPN transistor Q2, and finally enter into a locked state. At this time, most...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com