Anti-static protection structure and high-voltage integrated circuit

A high-voltage integrated circuit and protection structure technology, which is applied to circuits, electrical components, and electric solid-state devices, can solve the problem of small secondary breakdown current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

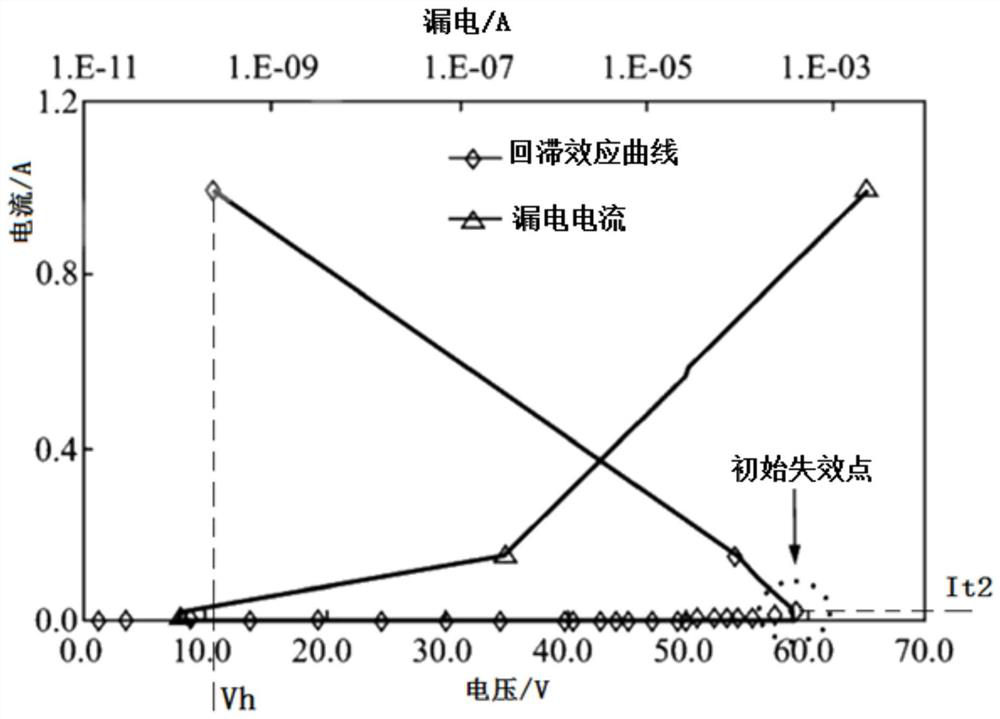

Problems solved by technology

Method used

Image

Examples

Embodiment 1

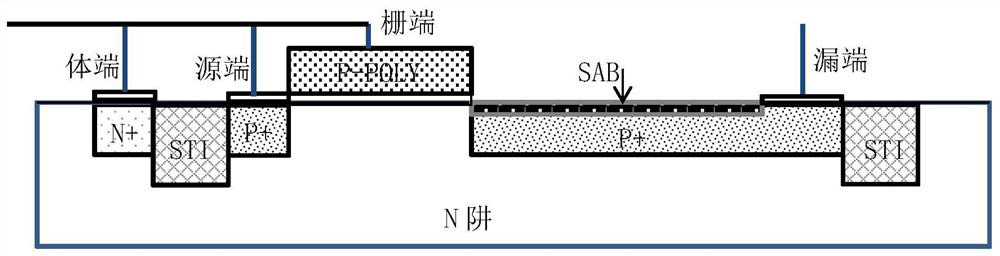

[0037] Such as Figure 4 As shown, the antistatic protection structure includes an N well 20 and a P well 30 formed in the substrate 10;

[0038] The upper and middle parts of the N well 20 and the P well 30 are separated by STI (Shallow Trench Isolation, shallow trench isolation) 40;

[0039] The lower parts of the N well 20 and the P well 30 are adjacent;

[0040] The upper part of the N well 20 is pasted with STI 40 and implanted with P-type heavy doping to form an N well P heavily doped region 24;

[0041] The upper part of the N well 20 is implanted with N-type heavy doping away from the STI 40 to form an N well N heavily doped region 22;

[0042] The upper part of the P well 30 is pasted with STI 40 and implanted with P-type heavy doping to form a P well P heavily doped region 26;

[0043] The N well P heavily doped region 24 is short-circuited with the N well N heavily doped region 22 to form an anode (anode) of the antistatic protection structure;

[0044] The P we...

Embodiment 2

[0047] Based on the antistatic protection structure of the first embodiment, the upper and middle parts of the N well 20 and the P well 30 are separated by the STI 40 .

[0048] Preferably, the N-type ion doping concentration of the N-well N heavily doped region 22 is greater than 10 times the N-type ion doping concentration of the N-well 20 .

[0049] Preferably, the P-type ion doping concentration of the N well P heavily doped region 24 and the P well P heavily doped region 26 is greater than 10 times the P type ion doping concentration of the P well 30 .

[0050] Preferably, the substrate 10 is P-type doped;

[0051] The doping concentration of the substrate 10 is smaller than that of the P-well.

Embodiment 3

[0053] Based on the antistatic protection structure of Embodiment 1, the distance a from the N well P heavily doped region 24 to the border between the N well 20 and the P well 30 is in the range of 0.2um to 2um;

[0054] The distance b from the P well P heavily doped region 26 to the border between the P well 30 and the N well 20 is in the range of 0.2um˜2um.

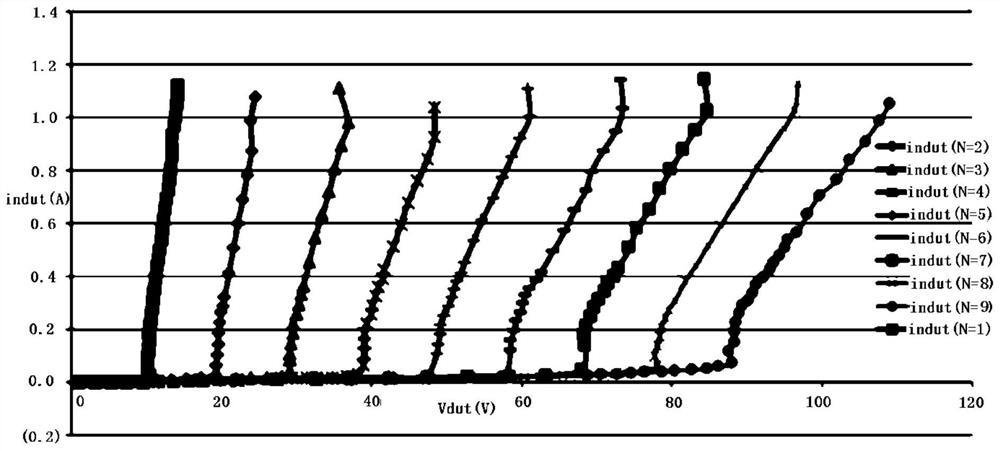

[0055] In the antistatic protection structure of the second embodiment, the trigger voltage (Vt1) is affected by parameters a and b within a certain range. Such as Figure 5 , Figure 6 As shown, in a certain process platform, when the values of a and b reach 0.5um, the reverse breakdown voltage reaches 19.1V, while the trigger voltage (Vt1) and holding voltage (Vh) reach about 20V, so the anti-static The protection structure can be applied to the anti-static protection design of the 32V high-voltage port by connecting two levels in series.

[0056] Embodiment Three

[0057] The high-voltage integrated circuit ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com