Pixel array substrate

A pixel array substrate and substrate technology, which is applied in the directions of optics, instruments, electrical components, etc., can solve the problems of large display gaps in the pixel area and disconnection of data lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

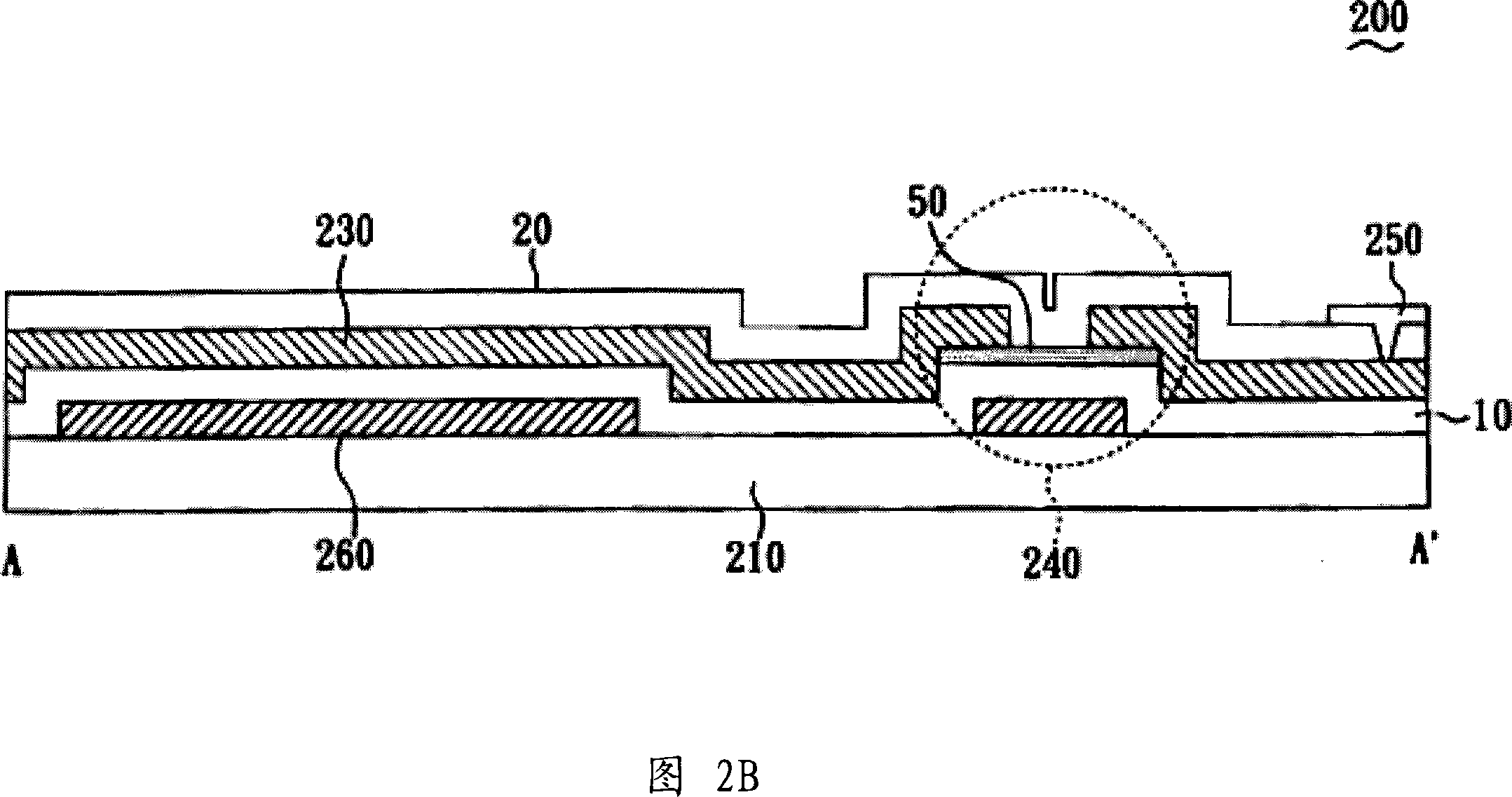

[0073] 3A is a partial top view of the pixel array substrate according to the first embodiment of the present invention, and FIG. 3B is a cross-sectional view of the pixel array substrate in FIG. 3A, wherein the section line is the line BB' in FIG. 3A. Please refer to FIG. 3A and FIG. 3B, the pixel array substrate 300a of the present invention includes a substrate 310 and a plurality of scanning lines 320, a plurality of data lines 330, a plurality of active elements 340, a plurality of pixel electrodes 350, A plurality of first patterned floating metals 360 and a plurality of first patterned connecting wires 370 . Wherein, a first insulating layer 391 is formed between the first patterned floating metal 360 and the data line 330, a second insulating layer 392 is formed above the data line 330, and a semiconductor layer is formed above the scanning line 220 of the active element 340. 393 on the first insulating layer 391. These data lines 330 and scan lines 320 form a plurali...

no. 2 example

[0080] FIG. 4 is a partial top view of a pixel array substrate according to a second embodiment of the present invention. Referring to FIG. 4 , the pixel array substrate 300b of this embodiment is similar to the pixel array substrate 300a of the first embodiment (as shown in FIG. 3A ). In this embodiment, a part of the pixel electrode 350 overlaps with the scan line 320 and forms an auxiliary capacitor 351 . Wherein, the pixel array substrate 300a further includes a plurality of contact windows 372 disposed on the substrate 310, and the contact windows 372 are electrically connected to the partially overlapping first patterned floating metal 360 and the first patterned connection wire 370. between. In other words, the first patterned floating metal 360 and the first patterned connection wire 370 on the same row have already passed through the contact window 372 to form wires similar to the parallel data lines 330 during fabrication.

[0081] Following the above, when the dis...

no. 3 example

[0084] 5A is a partial top view of a pixel array substrate according to a third embodiment of the present invention. Please refer to FIG. 5A , the pixel array substrate 300c of this embodiment is similar to the pixel array substrate 300a of the first embodiment (as shown in FIG. 3A ), the difference is that the first patterned floating metal 360 of this embodiment has a second A protrusion 366. In addition, the active element 340 is, for example, a thin film transistor, wherein the gate 342 of the active element 340 is electrically connected to the scan line 320 (in this embodiment, the gate 342 of the active element 340 is, for example, formed by a part of the scan line 320 formed), and the source 344 of the active element 340 is electrically connected to the data line 330 , and the drain 346 of the active element 340 is electrically connected to the pixel electrode 350 . In addition, the first protrusion 366 partially overlaps the drain 346 of the active device 340 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com