Single phase gas insulation switch device

A gas-insulated switch and equipment technology, which is applied in the setting of switchgear, switchgear, electrical components, etc., can solve the problems of being easily limited by external natural conditions, unable to make full use of land resources, and difficult to ensure normal operation, etc. To achieve the effect of reducing the volume, making full use of land resources, and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

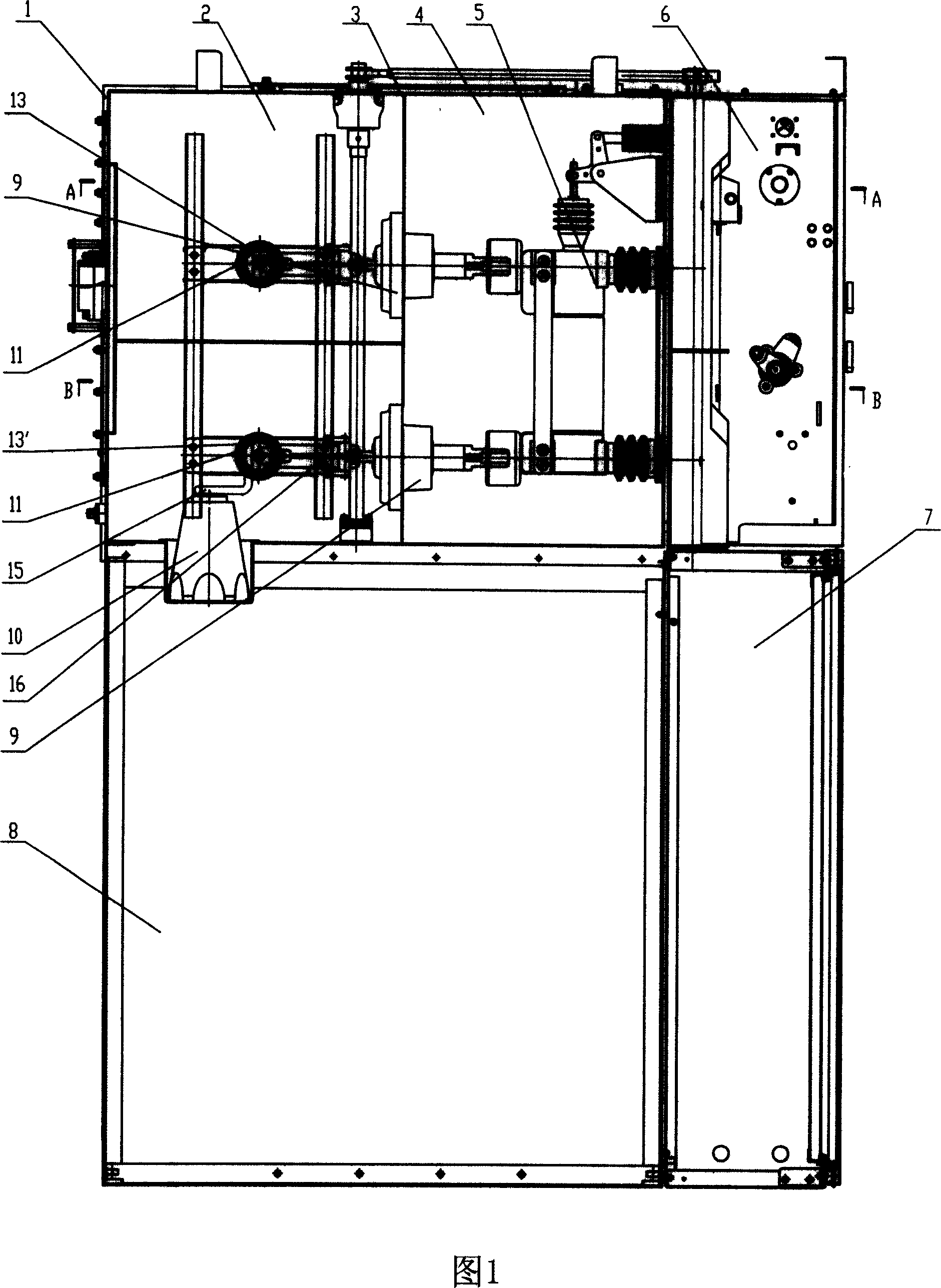

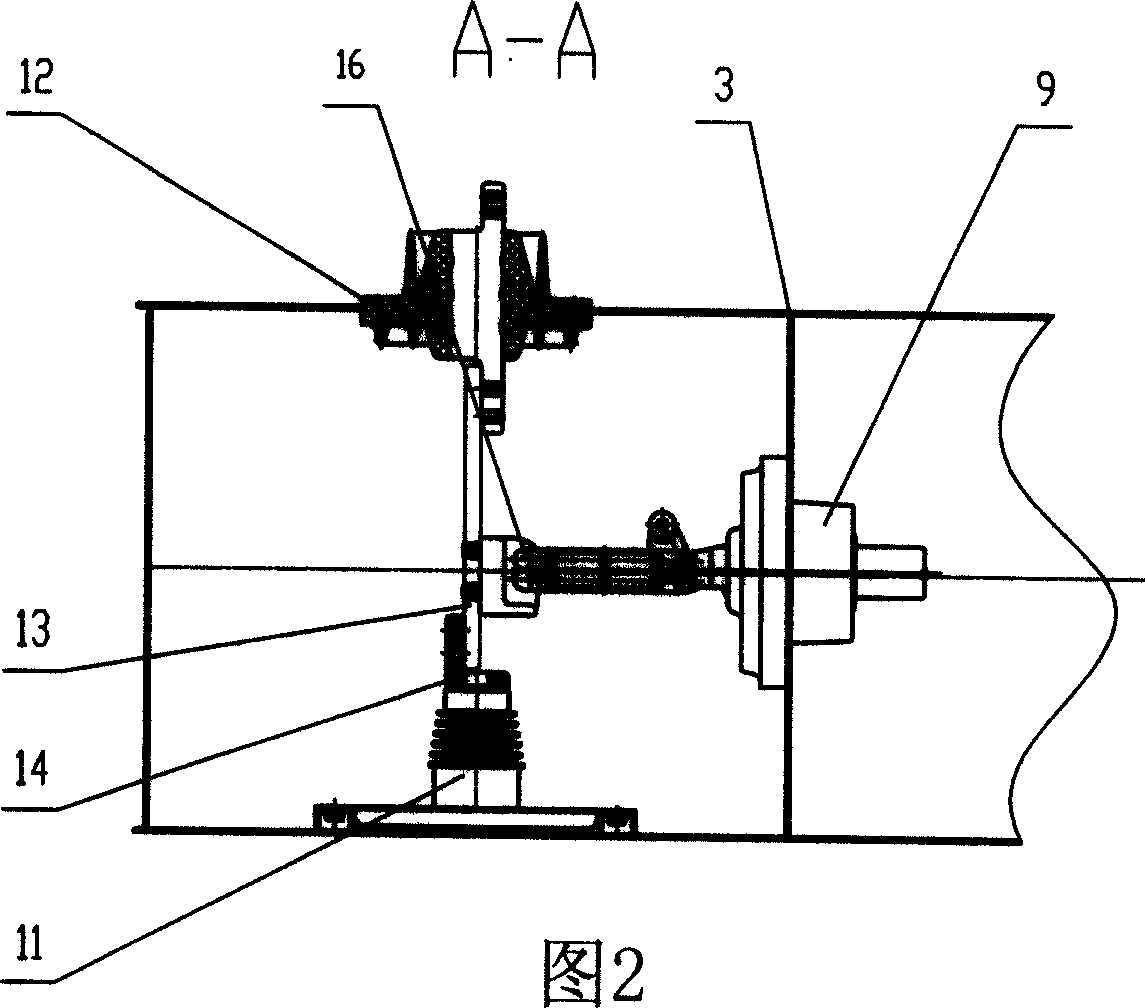

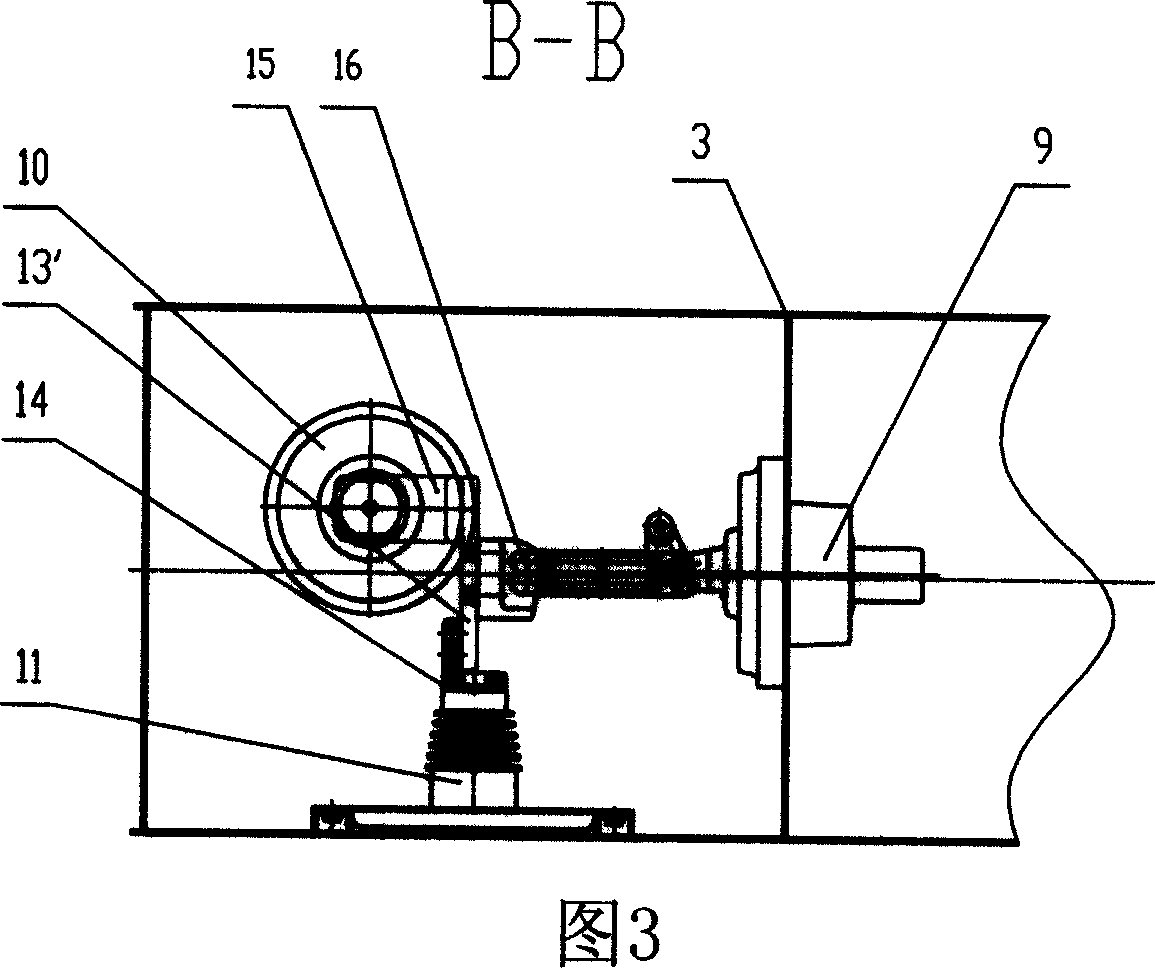

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0017] As shown in Figures 1 to 9, a single-phase gas-insulated switchgear is composed of a box body 1, a cable room 8, an instrument room 7, a circuit breaker 5, and an operating mechanism 6. The operating mechanism 6 is located on the outer surface of the box body 1. For the control of the switch, the box body 1 sits on the cable room 8 and is fixedly connected to the top of the cable room 8 by screws. The inner cavity of the box body 1 is divided into a relatively sealed bus room 2 and a circuit breaker room 4 by a partition plate 3. Busbar chamber 2 is provided with busbar connector 12, insulator 11, upper busbar 13, lower busbar 13', connecting bar 15, connecting block 14 and socket 10, one end of upper busbar 13 is connected with busbar connector 12, and the other end is connected by The block 14 is connected to the insulator 11, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com