Direct drinking machine

A direct drinking machine and wastewater technology, applied in the field of direct drinking machines, can solve the problems of high total soluble solids, high cost, and human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

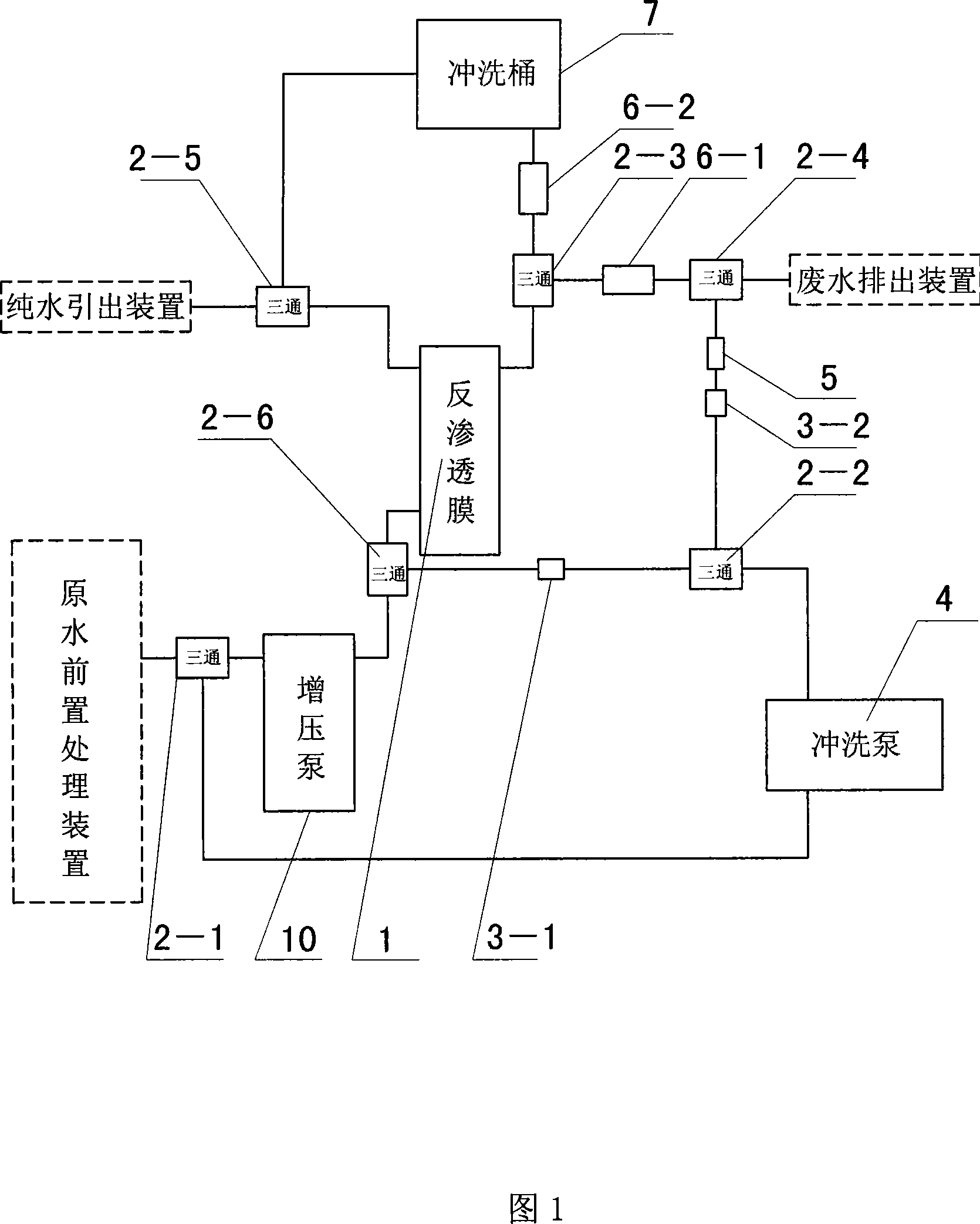

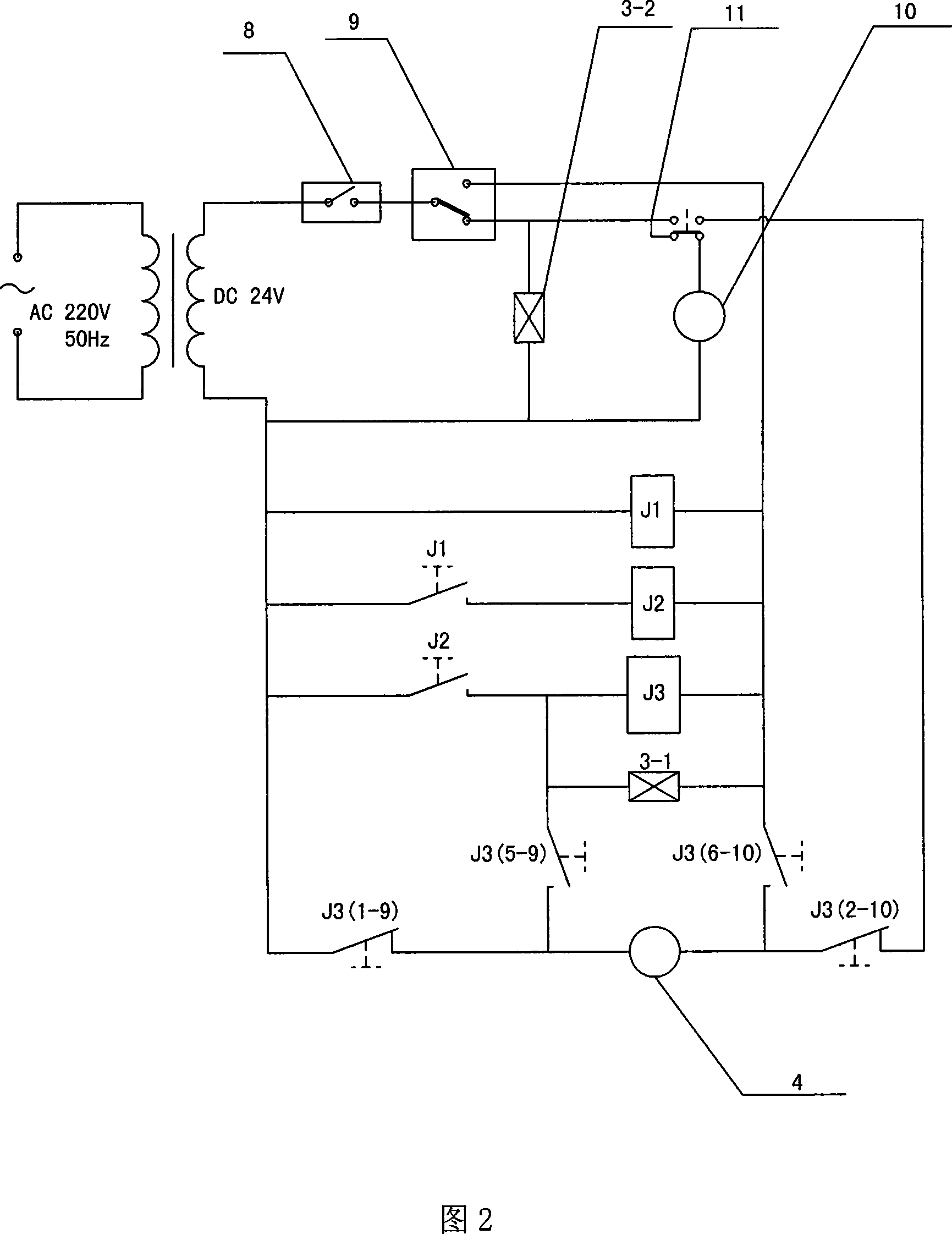

[0009] As shown in Fig. 1 and Fig. 2: connect together according to Fig. 1 and Fig. 2, install in a casing and make the flushing bucket 7 be arranged on the top of the reverse osmosis membrane 1 of large flow and promptly constitute a direct drinking water dispenser. Its working process is:

[0010] 1) When the raw water pressure is less than 5Kg, the normally closed contact of the high pressure switch is closed, and the solenoid valve 3-2 and the booster pump 10 work simultaneously. The raw water enters the water inlet of the reverse osmosis membrane 1 through the pretreatment device, the tee 2-1, the booster pump 10 and the tee 2-6. -5 enters the pure water extraction device, and the waste water enters the waste water discharge device through the three-way 2-3, the check valve 6-1 and the three-way 2-4; Solenoid valve 3-2, tee 2-2 and flushing pump 4 get back to tee 2-1 middle end. When the extraction of pure water is stopped, the pure water produced by the reverse osmosis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com