Hoisting electromagnet for elevating steel pipe

A technology for lifting electromagnets and lifting steel pipes, applied in the field of lifting electromagnets, can solve problems such as jamming, increased contact between steel pipes and magnetic poles, and falling of suspended steel pipes, so as to increase contact, improve lifting capacity, increase magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

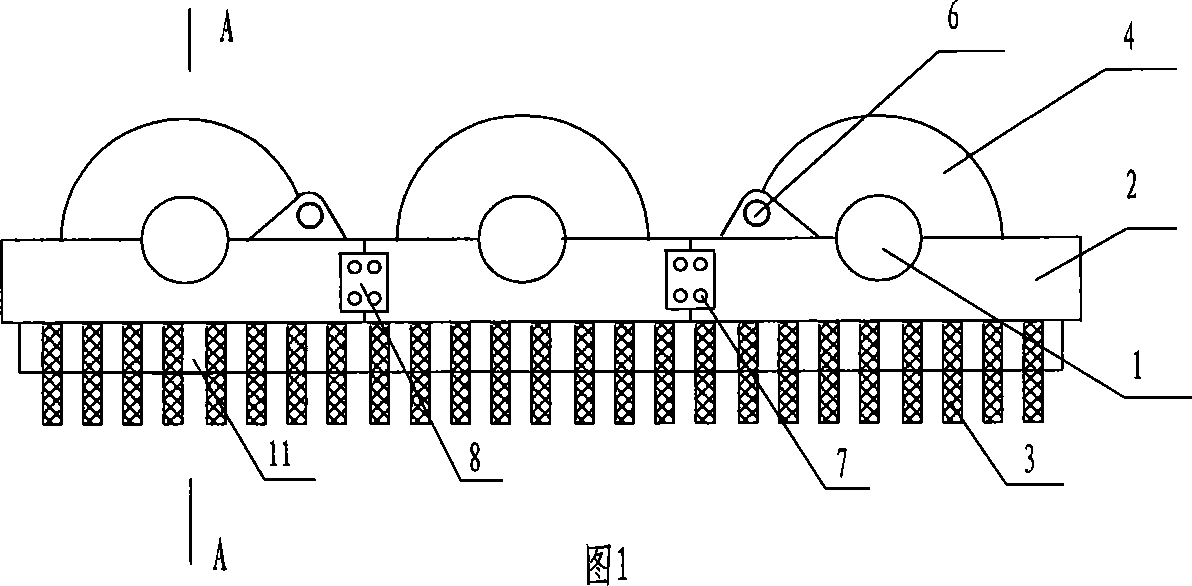

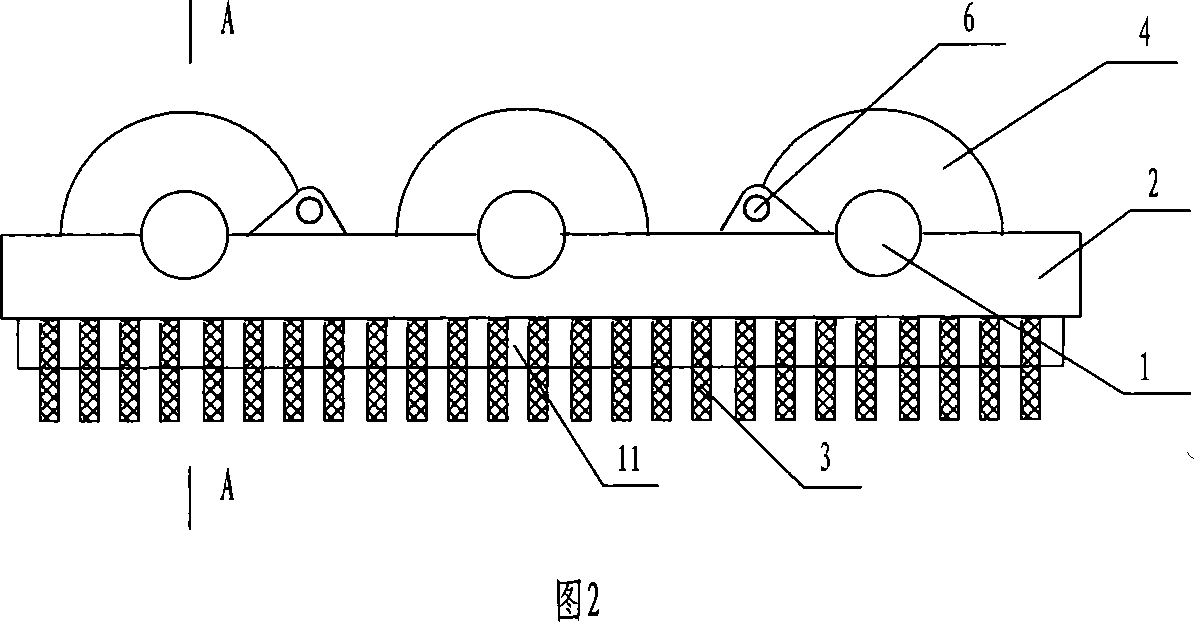

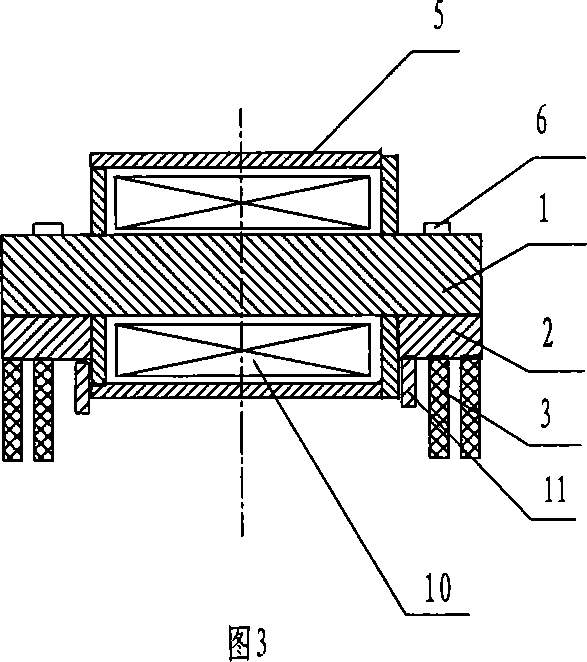

[0017] From Fig. 1, Fig. 3, Fig. 4, shown in Fig. 5, it can be seen that the structure of the hoisting electromagnet for hoisting steel pipes of the present invention is a "U" shaped electromagnet. It includes 3 small "U" shaped electromagnets; the iron core 1 is the yoke of the "U" shaped electromagnet, the iron core 1 has an excitation coil casing 4, and the ring plate 5 of the excitation coil casing 4 is an antimagnetic material After the excitation coil 10 is loaded into the excitation coil housing 4, the end plates are welded and sealed, and then the two ends of the iron core 1 are respectively connected to the two supporting plates 2 by welding; when each supporting plate 2 is close to the coil housing 4 The support plate 11 at the place can be multiple pieces, or it can be a rigid body. The present invention preferably welds a rigid support plate 11. The bottom surface of the support plate 11 is 10mm lower than the lower bottom surface of the coil housing 4, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com