Measurement and key installation method for tangential key grooves of trunnion of large and medium-sized converter

An installation method and tangential key technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems such as large interference, gluing, and scratches on the key surface, so as to avoid the installation cycle and meet the contact area Requirements, the effect of accurately measuring the size of the keyway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

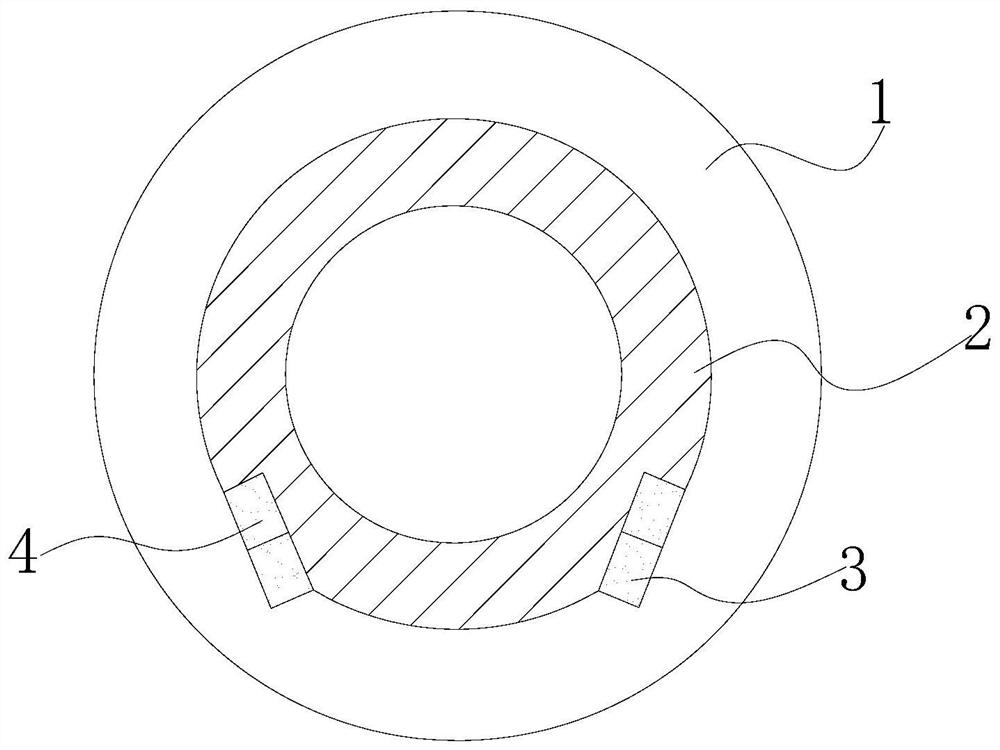

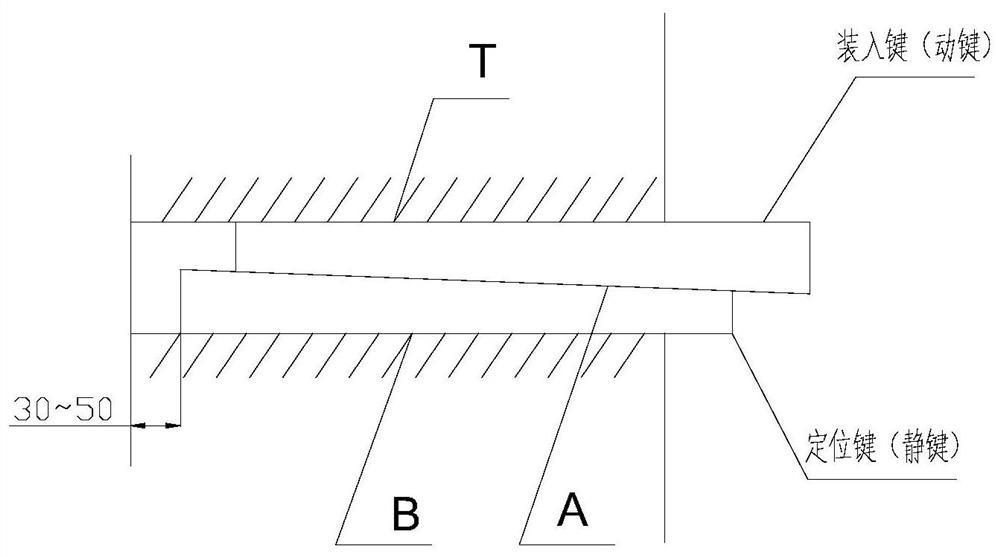

[0037]Example 1: ReferenceFigure 1-3, The present invention discloses a method for measuring and key installation of the tangential keyway of the trunnion of a large and medium-sized converter, which includes the following steps:

[0038]S1, the width of the key slot, processing a required measuring module, spare;

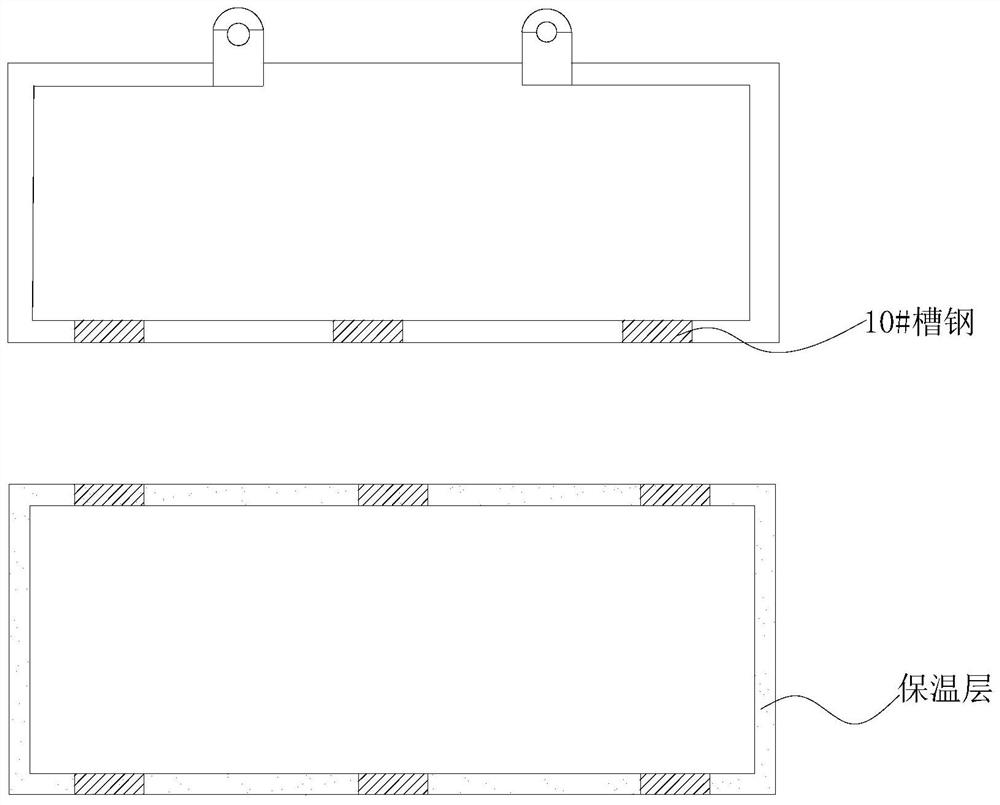

[0039]S2. Use section steel to make brackets to fix the converter body on both sides of the front and back of the converter to prevent the body from shaking and cause the keyway to be misaligned;

[0040]S3. Assemble the primary reducer and secondary large gear, and turn the primary reducer so that the keyways on both sides of the large gear are aligned with the keyways on both sides of the trunnion;

[0041]S4. Measure the width of the keyway on both sides with an internal micrometer to make the width on both sides basically the same, and the measurement error is controlled within 0.1mm;

[0042]S5. Place a dial indicator on the measuring module to measure the size of the keyway of th...

Embodiment 2

[0054]Example 2: ReferenceFigure 1-3, The present invention discloses a method for measuring and key installation of the tangential keyway of the trunnion of a large and medium-sized converter, which includes the following steps:

[0055]S1, the width of the key slot, processing a required measuring module, spare;

[0056]S2. Use section steel to make brackets to fix the converter body on both sides of the front and back of the converter to prevent the body from shaking and cause the keyway to be misaligned;

[0057]S3. Assemble the primary reducer and secondary large gear, and turn the primary reducer so that the keyways on both sides of the large gear are aligned with the keyways on both sides of the trunnion;

[0058]S4. Measure the width of the keyway on both sides with an internal micrometer to make the width on both sides basically the same, and the measurement error is controlled within 0.1mm;

[0059]S5. Place a dial indicator on the measuring module to measure the size of the keyway of th...

Embodiment 3

[0071]Example 3: ReferenceFigure 1-3, The present invention discloses a method for measuring and key installation of the tangential keyway of the trunnion of a large and medium-sized converter, which includes the following steps:

[0072]S1, the width of the key slot, processing a required measuring module, spare;

[0073]S2. Use section steel to make brackets to fix the converter body on both sides of the front and back of the converter to prevent the body from shaking and cause the keyway to be misaligned;

[0074]S3. Assemble the primary reducer and secondary large gear, and turn the primary reducer so that the keyways on both sides of the large gear are aligned with the keyways on both sides of the trunnion;

[0075]S4. Measure the width of the keyway on both sides with an internal micrometer to make the width on both sides basically the same, and the measurement error is controlled within 0.1mm;

[0076]S5. Place a dial indicator on the measurement module to measure the size of the keyway of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com