Crane electromagnetic for hoisting high temperature circular pipe blank

A technology for lifting electromagnets and round tube blanks, which is applied in the field of lifting electromagnets, can solve the problems of large volume and weight of electromagnets, low suction weight, falling of high temperature round tube blanks, etc., so as to improve the lifting capacity and increase the Magnetic force, the effect of increasing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

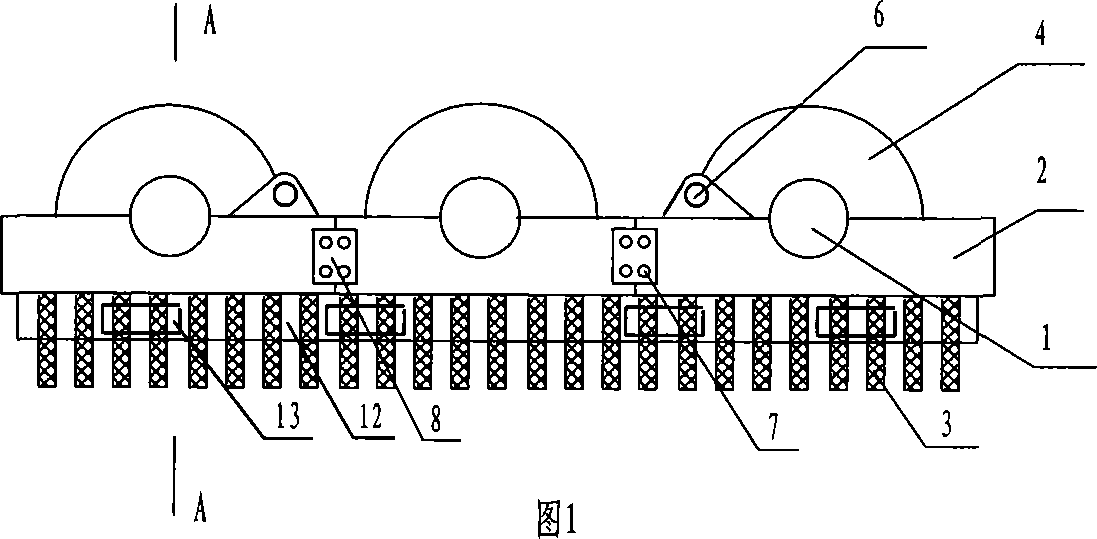

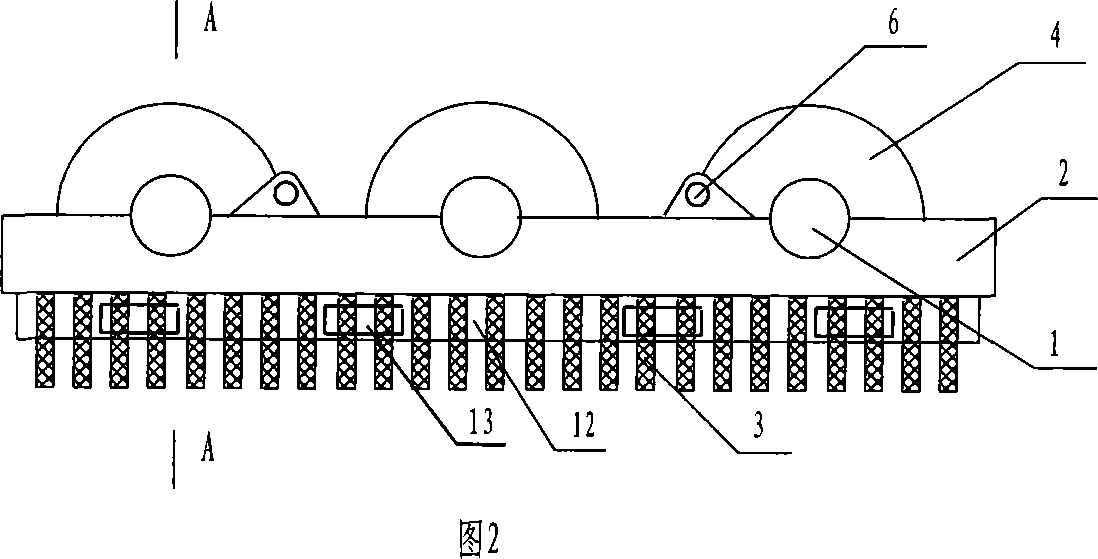

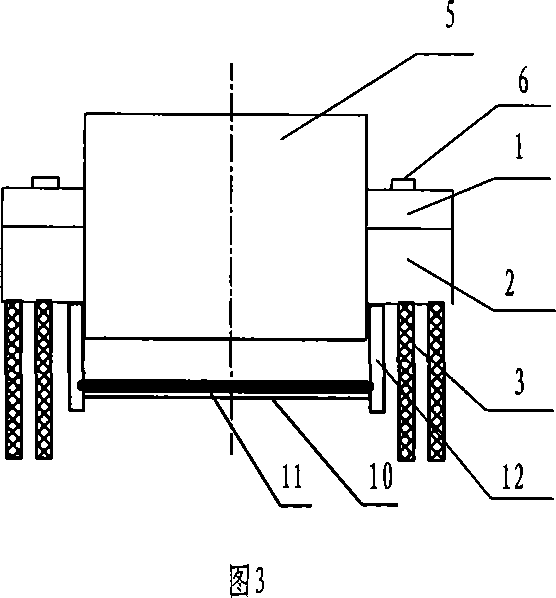

[0017] It can be seen from Fig. 1, Fig. 3 and Fig. 4 that the structure of the electromagnet for lifting the high-temperature circular tube billet of the present invention is a "U"-shaped electromagnet. It includes 3 small "U" shaped electromagnets; the iron core 1 is the yoke of the "U" shaped electromagnet. After the exciting coil 9 is loaded into the exciting coil shell, the end plate 4 is welded and sealed, and then the two ends of the iron core 1 are respectively connected to the two supporting plates 2 by welding; each supporting plate 2 is close to the end plate 4 of the coil shell Each support plate 12 perpendicular to it is welded at the bottom of each place, the length of the plate is slightly smaller than the length of the supporting plate 2, a ventilation hole 13 is opened on each support plate 12, and a non-magnetic conduction hole is welded between the two support plates 12 anti-radiation plate 10, the length of this plate is equal to the length of support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com