Anti-drop method used for sintering epoxy powder anti-corrosive counterweight tube

A technology of sintering epoxy powder and counterweight pipe, which is applied in the direction of anti-corrosion/anti-rust protection of pipelines, pipes, rigid pipes, etc., can solve the problems of easy slippage of the coating and poor bonding performance, and achieves enhanced working conditions. The effect of improving the resistance to shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

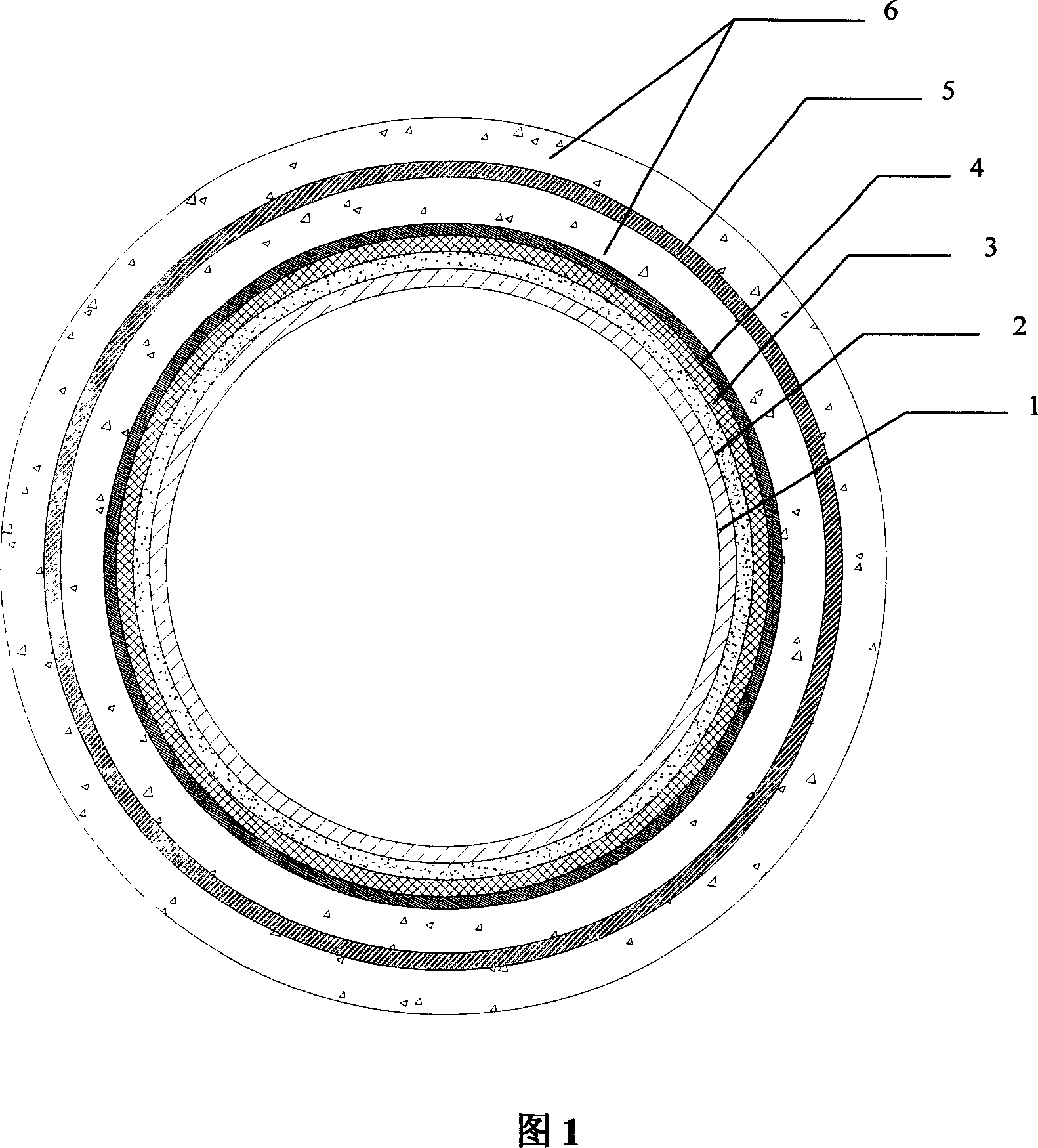

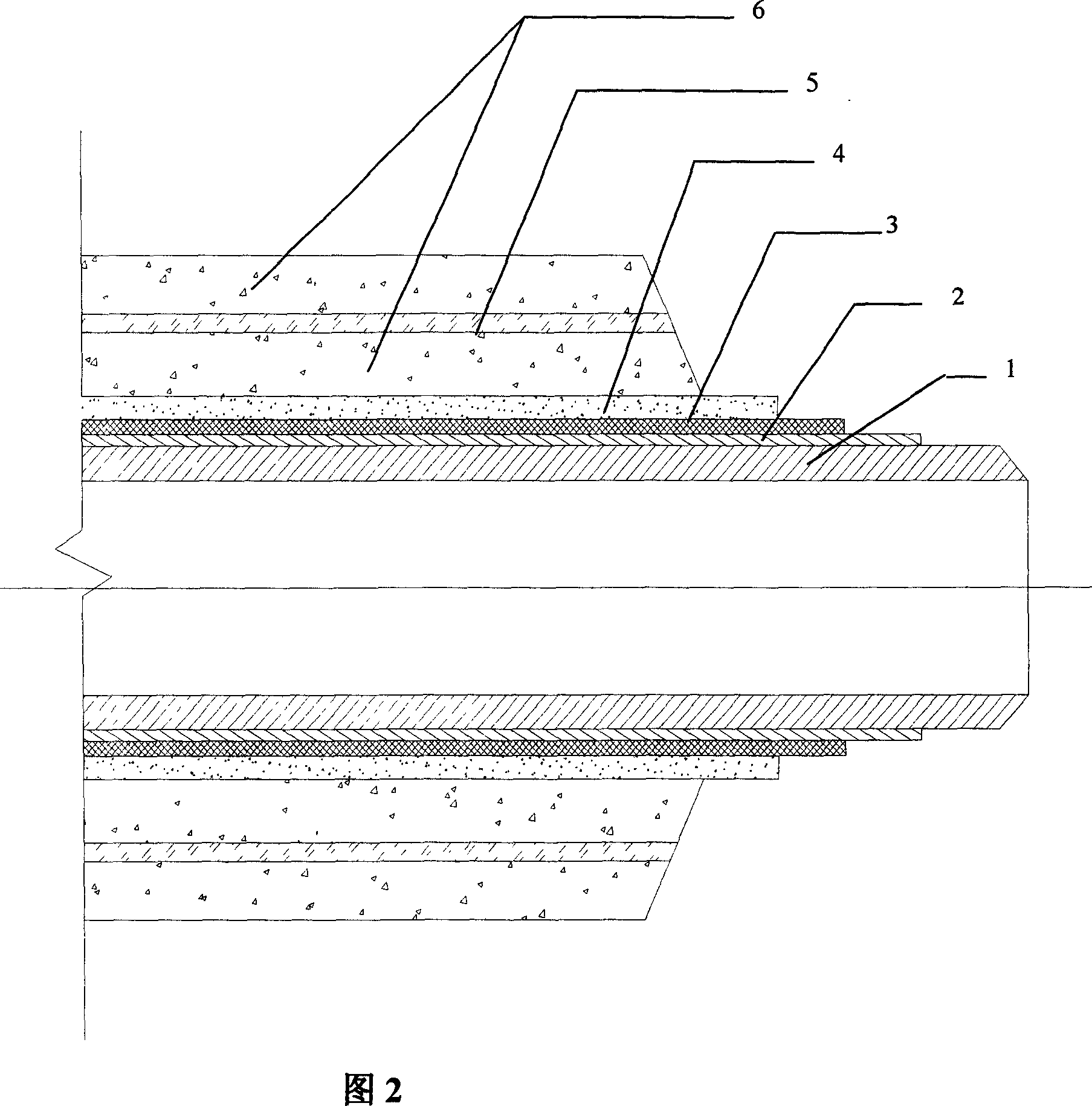

[0022] The surface of the steel pipe is sandblasted, and a layer of fusion-bonded epoxy powder anti-corrosion layer is coated on the outside of the steel pipe. The anti-corrosion layer is coated with a polyolefin copolymer adhesive for bonding non-slip particles, and the anti-slip particles are coated with polyethylene-based resin on the adhesive. Granules, and finally carry out the coating construction of the concrete counterweight layer, and a reinforcement layer is arranged in the concrete counterweight layer, which is reinforced by a steel mesh structure. After testing, the shear resistance between the anti-corrosion layer of the weight pipe and the concrete coating is greater than 0.1N / mm 2 .

Embodiment 2

[0024] The surface of the steel pipe is sanded, and a layer of fusion-bonded epoxy powder anti-corrosion layer is coated on the outside of the steel pipe. The anti-corrosion layer is coated with a polyolefin copolymer adhesive for bonding non-slip particles, and anti-slip particles are coated on the adhesive. Polypropylene-based resin Granules, and finally carry out the coating construction of the concrete counterweight layer, and a reinforcement layer is arranged in the concrete counterweight layer, which is reinforced by a steel mesh structure. After testing, the shear resistance between the anti-corrosion layer of the weight pipe and the concrete coating is greater than 0.1N / mm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com