Preparation method for light sensitive planographic printing plate material

A technology for lithographic printing and plate materials, which is applied in the coating solution of photosensitive lithographic printing plates and the preparation of photosensitive lithographic printing plates, and can solve problems such as poor practicability, scratches on the back of plates, and hidden dangers of infrared radiation devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

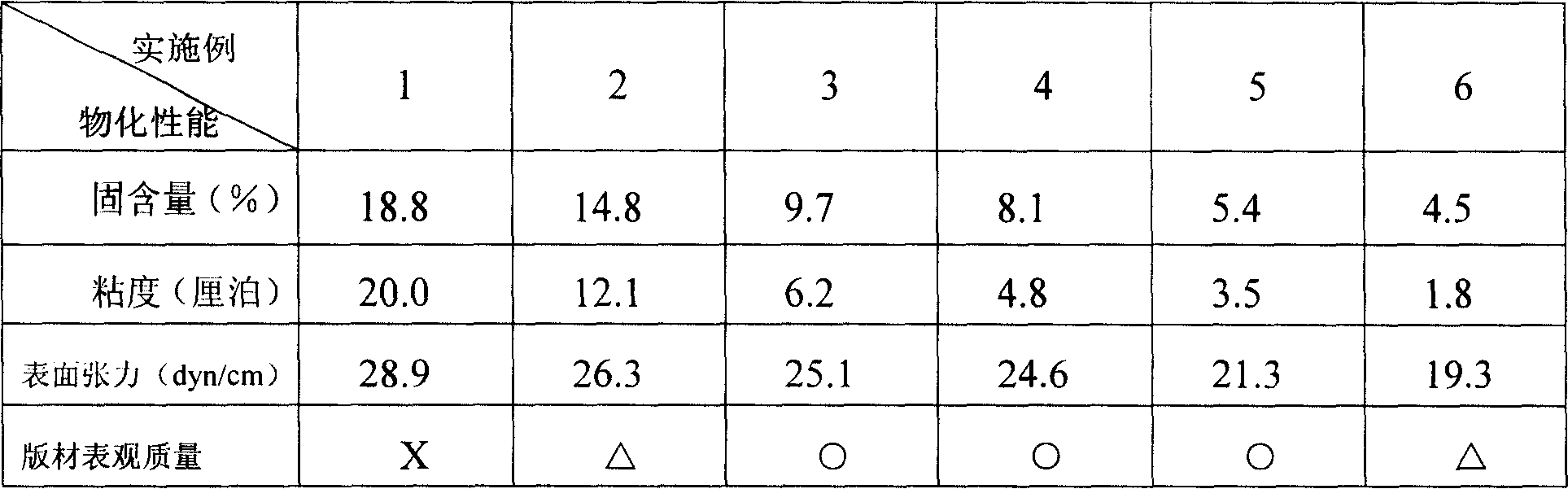

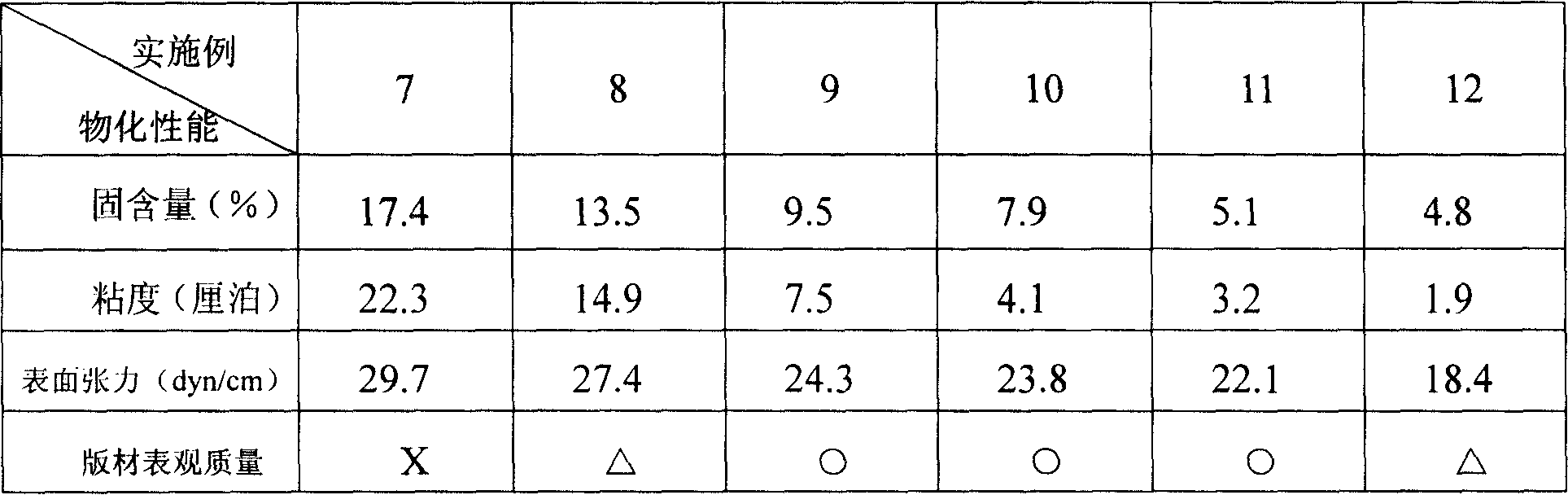

Embodiment 1

[0020] The present invention includes a drying method mainly adopting five stages: the drying part can be divided into five parts: one stage of drying, two stages of drying, three stages of drying, four stages of drying, and five stages of drying. Negative pressure control is adopted in the first drying section, and the dry waste gas is adsorbed and recovered by an activated carbon fiber device; the first drying section is the leveling section of the coating liquid, the drying temperature is controlled at 60°C, and the drying time is 12 seconds; the drying second section Negative pressure control is adopted in one section, and the negative pressure control is 10mmHg; the second drying section is a pre-drying section, and the drying temperature for preparing PS plates is controlled at 100°C, and the drying time is controlled at 30 seconds; for preparing CTP plates, the drying temperature is controlled at 110°C , the time control is 30 seconds. The third section of drying is the...

Embodiment 2

[0024]The present invention includes a drying method mainly adopting five stages: the drying part can be divided into five parts: one stage of drying, two stages of drying, three stages of drying, four stages of drying, and five stages of drying. Negative pressure control is adopted in the first drying section, and the dry waste gas is adsorbed and recovered by an activated carbon fiber device; the first drying section is the leveling section of the coating liquid, the drying temperature is controlled at 70°C, and the drying time is 10 seconds; the drying second section Negative pressure control is adopted in one section, and the negative pressure control is 20mmHg; the second drying section is a pre-drying section, and the drying temperature for preparing PS plates is controlled at 110°C, and the drying time is controlled at 20 seconds; for preparing CTP plates, the drying temperature is controlled at 120°C , the time control is 20 seconds. The third section of drying is the ...

Embodiment 3

[0028] The present invention includes a drying method mainly adopting five stages: the drying part can be divided into five parts: one stage of drying, two stages of drying, three stages of drying, four stages of drying, and five stages of drying. Negative pressure control is adopted in the first drying section, and the dry waste gas is adsorbed and recovered by an activated carbon fiber device; the first drying section is the leveling section of the coating liquid, the drying temperature is controlled at 80°C, and the drying time is 6 seconds; the drying second section Negative pressure control is adopted in one section, and the negative pressure control is 30mmHg; the second drying section is a pre-drying section, and the drying temperature for the preparation of PS plates is controlled at 120°C, and the time is controlled for 15 seconds; for the preparation of CTP plates, the drying temperature is controlled at 130°C , the time control is 15 seconds. The third section of dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com