Inductor element and method for production thereof, and semiconductor module with inductor element

A technology of inductance components and semiconductors, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of insufficient sintering of the ferrite magnetic layer, etc. The effect of the high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

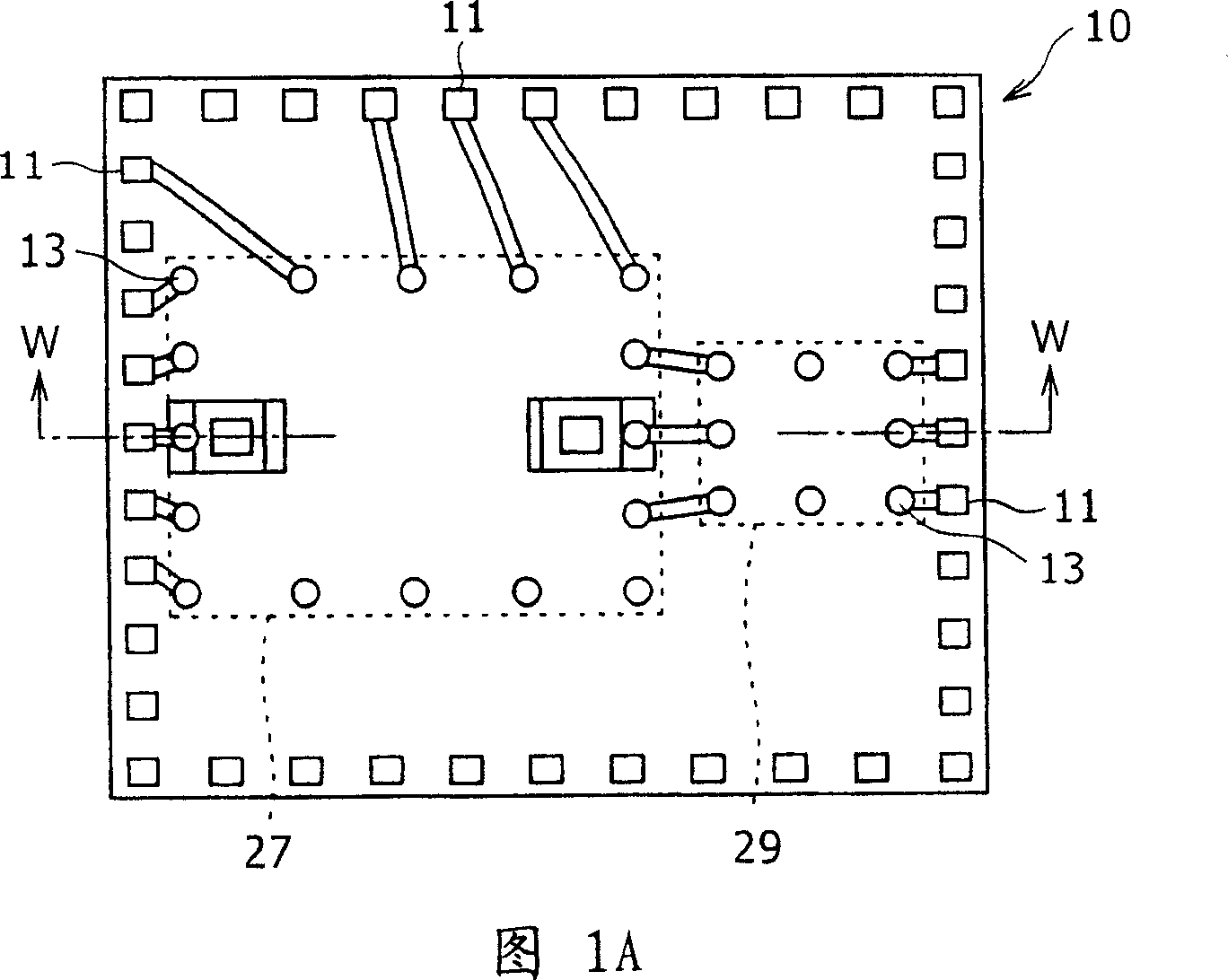

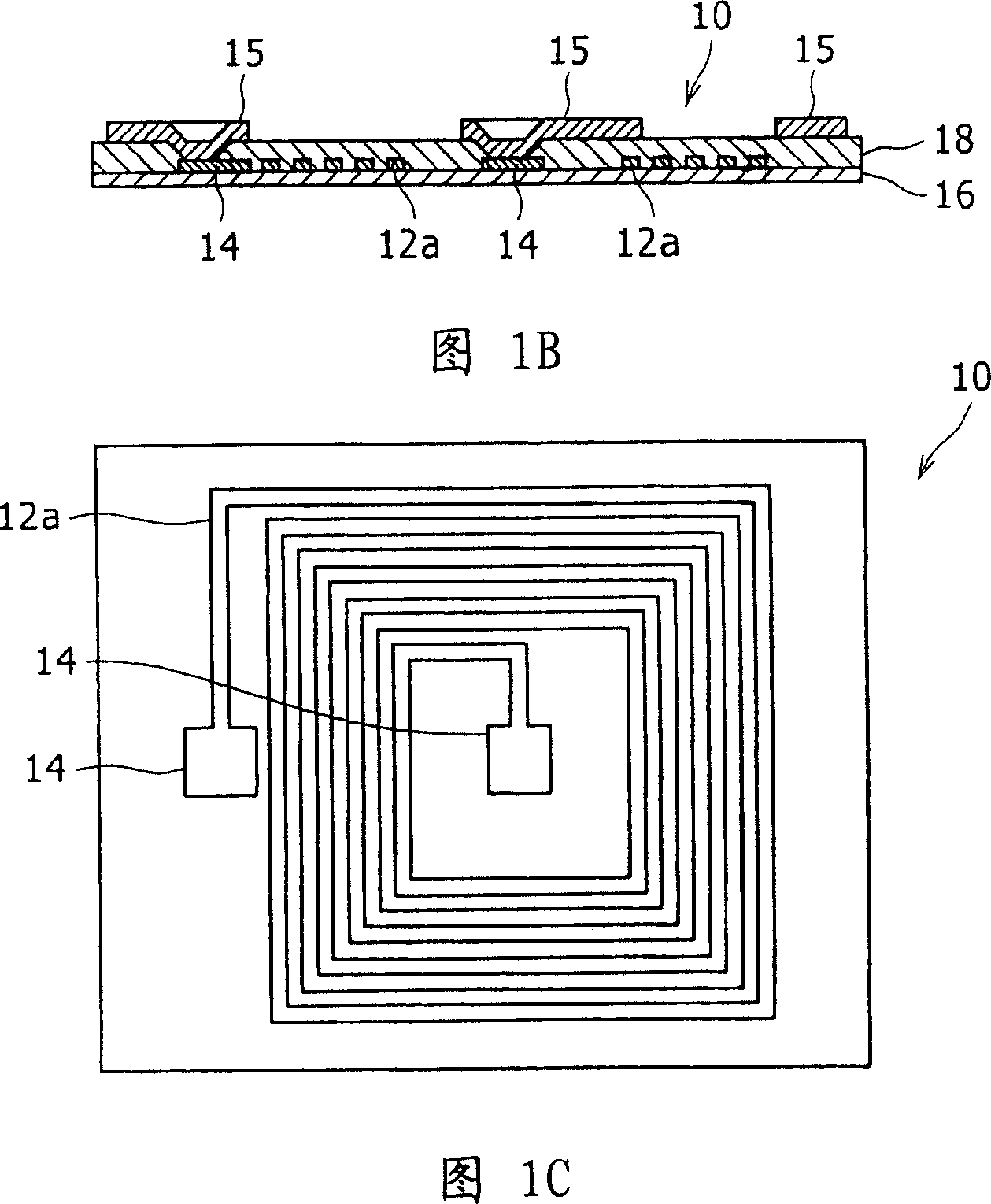

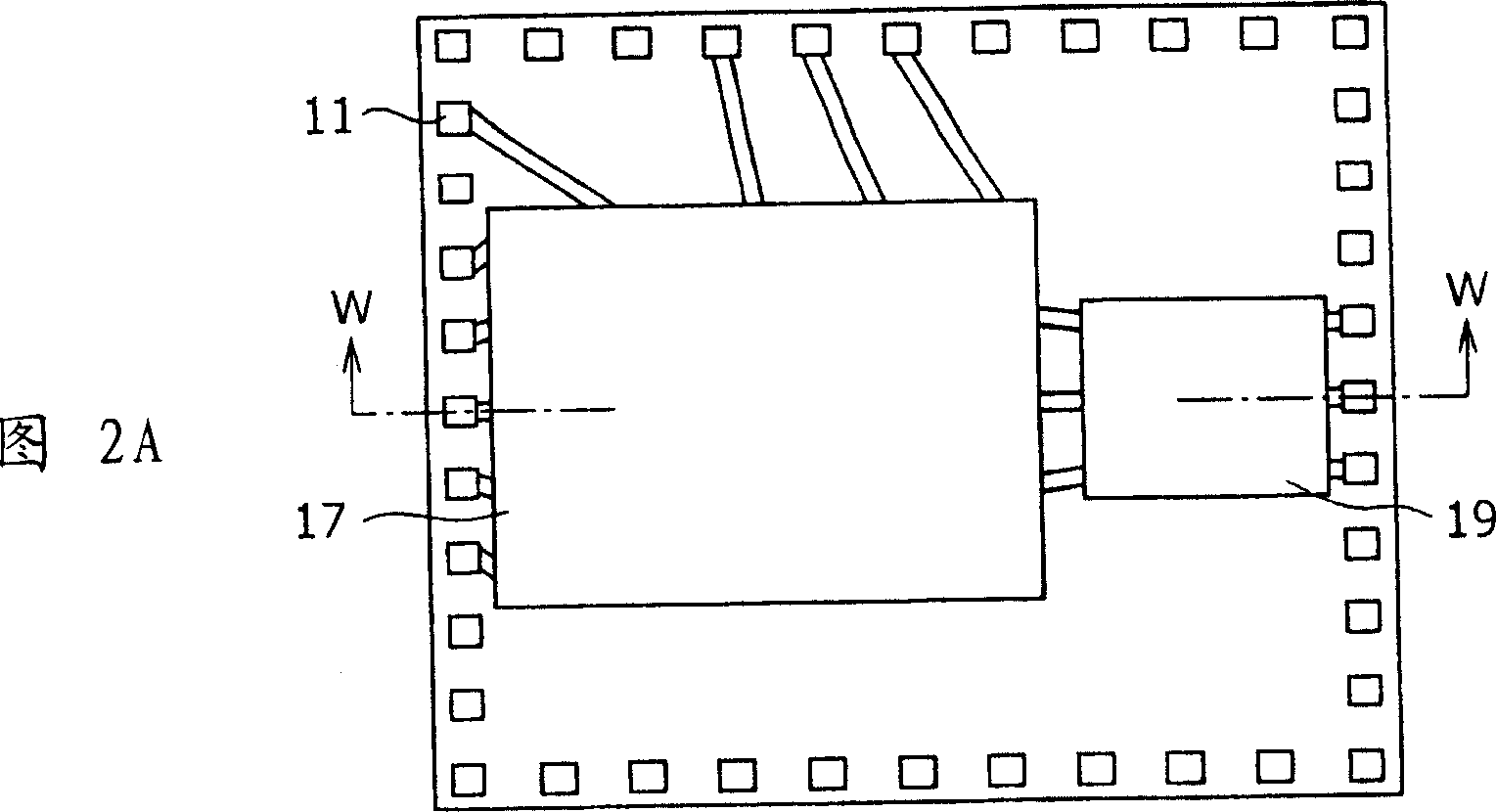

[0061] An inductance element according to an embodiment of the present invention should have both a magnetic material substrate and a magnetic material layer formed of a high magnetic permeability material such that the coil is embedded within the high magnetic permeability material. This structure makes the inductance element exhibit a large inductance.

[0062] Both the magnetic material substrate and the magnetic material layer should preferably be formed of ferrite. The magnetic material having a thickness of 50 μm formed of ferrite by aerosol deposition has a compact structure, so that the inductance element is thin and small in size but has a large inductance.

[0063] The coil should preferably be a planar coil thicker than 50 μm so that it has a large cross-sectional area to allow a large allowable current (maximum current) to flow through the inductive element.

[0064] The inductive element should have a terminal connected to the end of the coil on the outside of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com