Copper belt reeled H-grade insulation dry-type hollow self-cooled smoothing reactor

A technology of smoothing reactors and copper strips, applied in the direction of transformers/inductor coils/windings/connections, etc., can solve the problems of difficult heat dissipation of reactor coils, failure to achieve the best effect, and many materials, so as to avoid local temperature The effect of high rise, good elasticity and good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

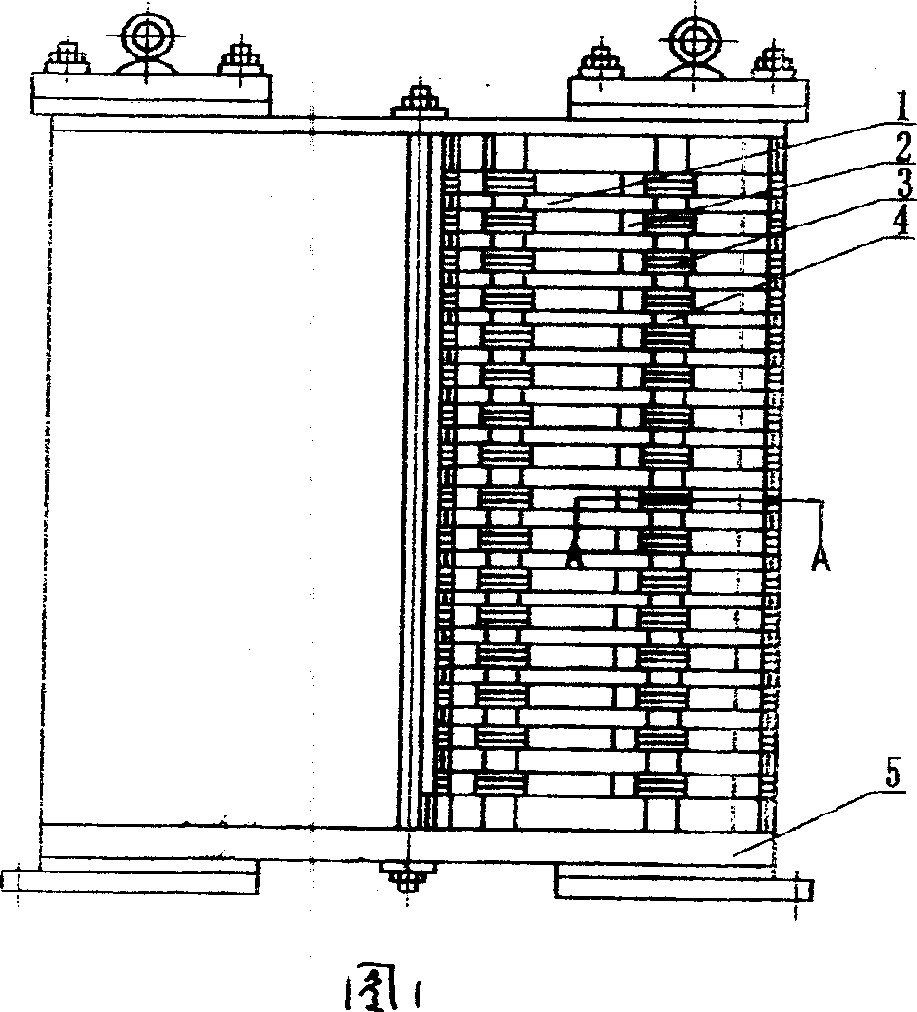

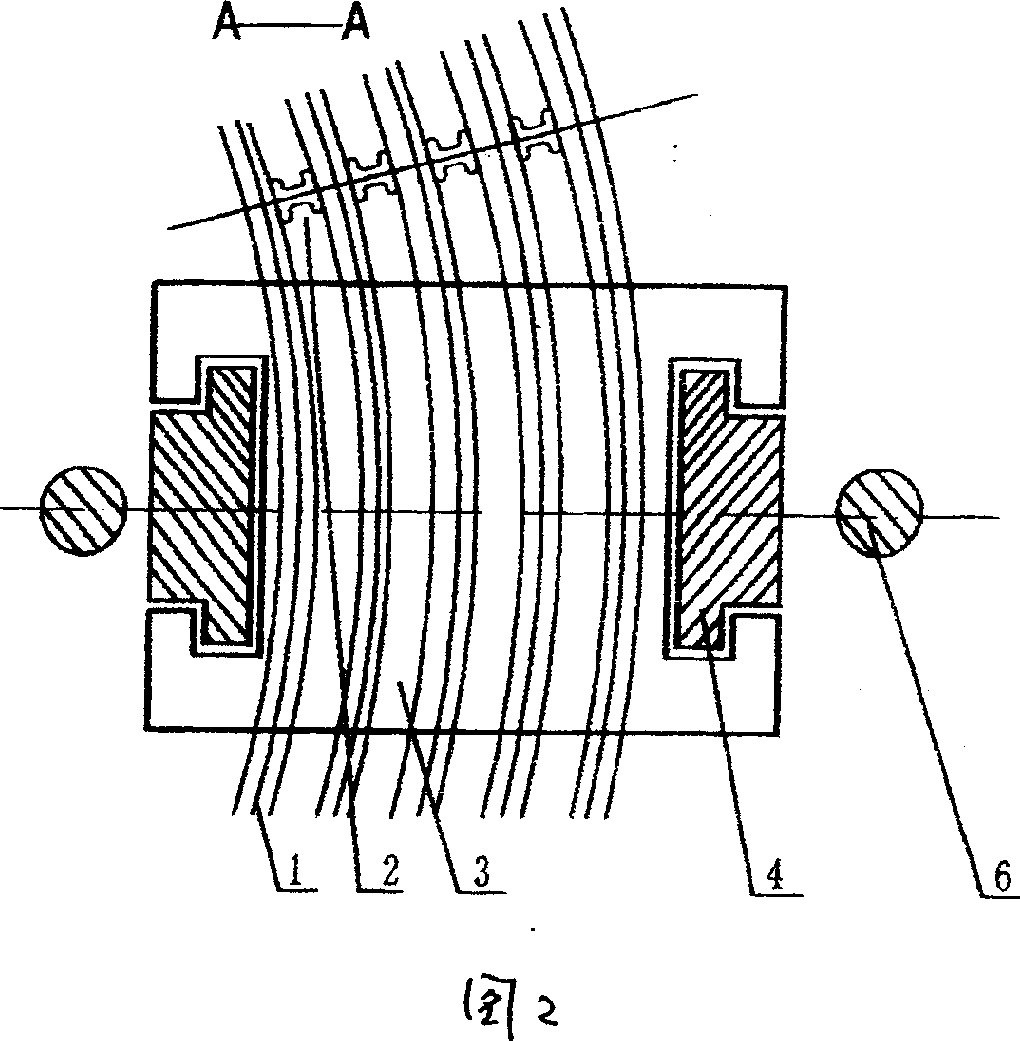

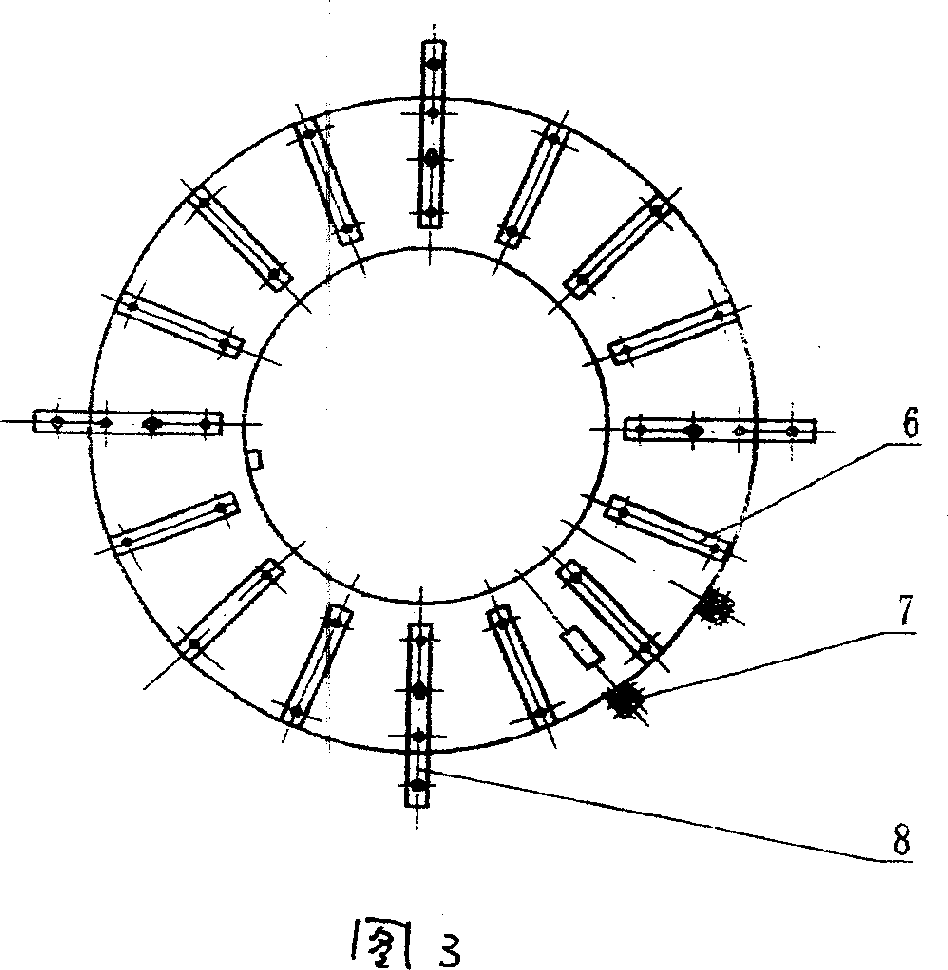

[0022] See Fig. 1, Fig. 2, Fig. 3, H-level insulated dry-type hollow self-cooling smoothing reactor wound with copper tape, including coils composed of bare copper tape 1, insulating air duct strip 2, and insulating high-frequency glass fiber pad 3 , Inner and outer insulating stays 4, insulating pressure plates 5, non-magnetic stainless steel pull rods 6, outlet terminals 7, foot plates 8, the inner and outer insulating stays, insulating air duct strips, and insulating spacers are all made of H-grade insulating materials.

[0023] There is an inner insulation stay 4 outside the iron shape of the tooling in the inner layer of the coil, and the wire wound outside the inner insulation stay is a bare copper strip 1, and the bare copper strip 1 is connected in parallel with 3 bare copper strips for each turn, 3 pieces for each coil The bare copper strips are drawn out at 120° according to the circumference of the coil, and the adjacent two pies are butted, so that the parallel wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com