Insulator plate of machine winding coil

A technology of motor windings and insulating sheets, which is applied to the shape/style/structure of winding insulation and the laying of solid insulation, etc. It can solve the problems of reduced production efficiency, broken connecting strips, and waste products, so as to increase the contact area and improve production efficiency. , the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

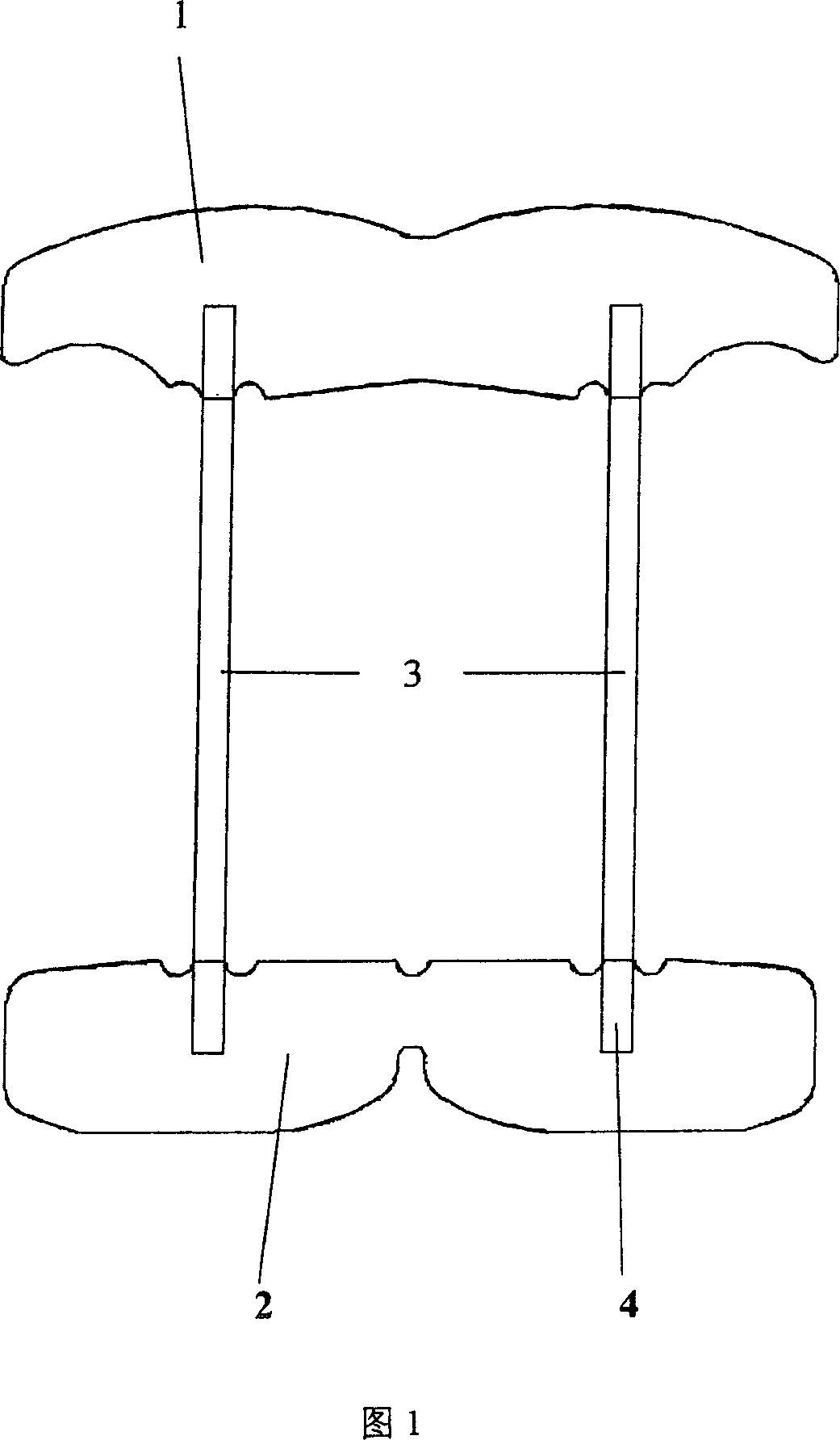

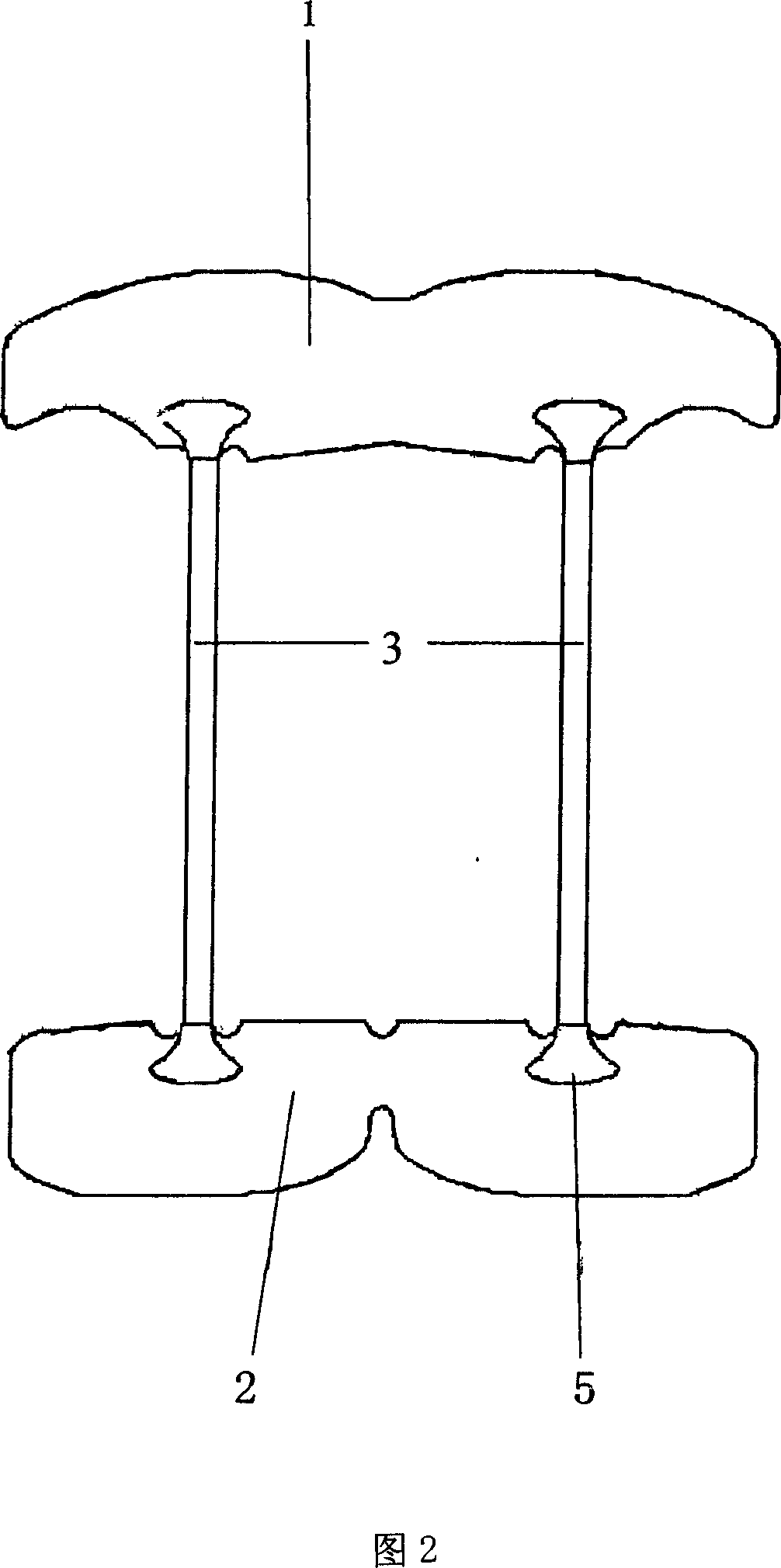

[0022] FIG. 2 is a schematic diagram of the insulating sheet of the present invention. As shown in the figure, the insulating sheet of the present invention is composed of an upper sheet 1 , a lower sheet 2 and a connecting strip 3 . The upper sheet 1 is a shape in which two fan shapes are connected together, and a bow-shaped notch is formed at its left and right lower corners, and a notch is formed at the welding place at its lower end. The lower piece 2 is a shape in which two quadrilaterals are connected together, the lower end of the quadrilateral is arc-shaped, and the upper end of the lower piece has a gap at the weld. The connecting bar body 3 is rectangular, and its two ends 5 are fan-shaped. The upper sheet, the lower sheet and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com