Bamboo-plastic floorboard and its production process

A technology for flooring and bamboo plastic, applied in the field of imitation solid wood flooring, can solve the problems of environmental pollution, waste of resources, economic losses and other problems of enterprises, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

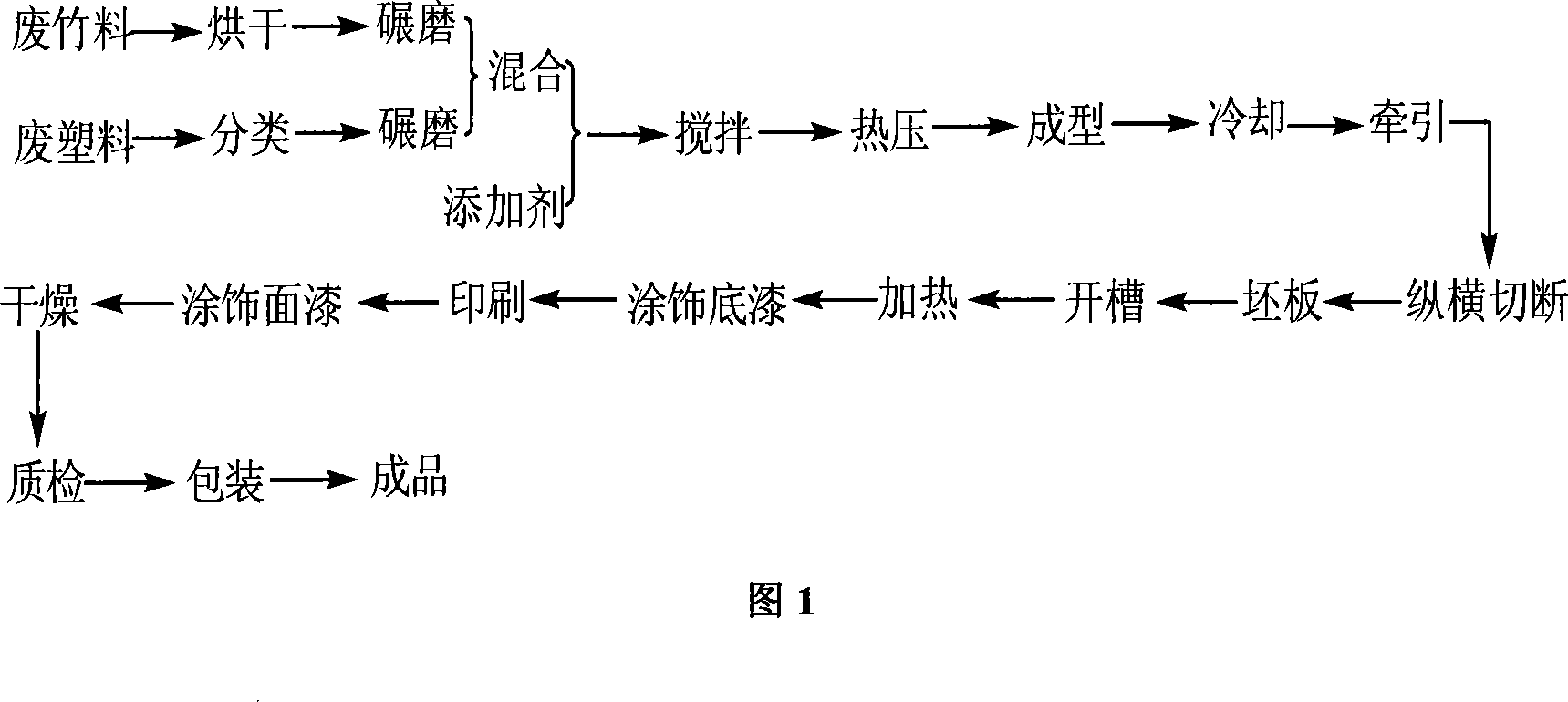

Method used

Image

Examples

Embodiment 1

[0019] The format is mm: 2440×1220×15 The manufacturing method of imitation solid wood bamboo plastic floor:

[0020] (1) Prepare raw materials for the first molding: bamboo chips, bamboo chips, bamboo sticks, bamboo scraps and other waste materials and waste plastics.

[0021] (2) Grinding waste bamboo materials into 70-90 mesh granules; grinding waste plastic polyethylene into 5mm granules to prepare bamboo granules and plastic granules respectively.

[0022] (3) Ratio: Bamboo granules and plastic granules in a ratio of 5:5.

[0023] (4) Additives: adding 0.5% maleic anhydride to the total mass of bamboo granules and plastic granules.

[0024] (5) Stirring: Stir evenly.

[0025] (6) Hot pressing: the hot pressing temperature is controlled at 165-195°C, the hot pressing pressure is controlled at 5 MPa-10 MPa, and the hot pressing time is 20 seconds per mm of plate thickness.

[0026] (7) Molding: ensure high cooling rate of the product, uniformity, and effectively ensure t...

Embodiment 2

[0038] The format is mm: 1200×125×12 The physical and chemical properties of the imitation solid wood bamboo plastic flooring products

[0039] The test results are as follows:

[0040] Water absorption: 30MPa, formaldehyde emission: 0 (According to the national mandatory standard of GB18580-2001 "Interior Decoration and Renovation Materials": the formaldehyde emission must be less than 1.5mg / L before the board can be directly used for interior decoration).

Embodiment 3

[0042] The format is mm: 2440×1220×12 The manufacturing method of imitation solid wood bamboo plastic floor:

[0043] (1) Prepare raw materials for the first molding: bamboo chips, bamboo chips, bamboo sticks, bamboo scraps and other waste materials and waste plastics.

[0044] (2) Grind waste bamboo into 70-90 mesh granules; waste plastic polypropylene, grind into 5mm granules.

[0045] (3) Ratio: Bamboo granules and plastic granules in a ratio of 5:5.

[0046] (4) Additives: add 2% of the total mass of bamboo material particles and plastic particles to modify maleic anhydride. The modifying agent is isocyanate glue, and the ratio of maleic anhydride and isocyanate glue in the additive is 95%:5%.

[0047] (5) Stirring: Stir evenly.

[0048](6) Hot pressing: the hot pressing temperature is controlled at 165-195°C, the hot pressing pressure is controlled at 5-8MPa, and the hot pressing time is 20 seconds per mm of plate thickness.

[0049] (7) Molding: ensure high cooling r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com