Circular granular sludge reactor

A granular sludge and reactor technology, which is applied in the field of circulating granular sludge reactors, can solve the problems of affecting the processing capacity of anaerobic reactors, insufficient bacterial activity, and dead zones in reactors. Small, high load, and the effect of preventing the loss of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

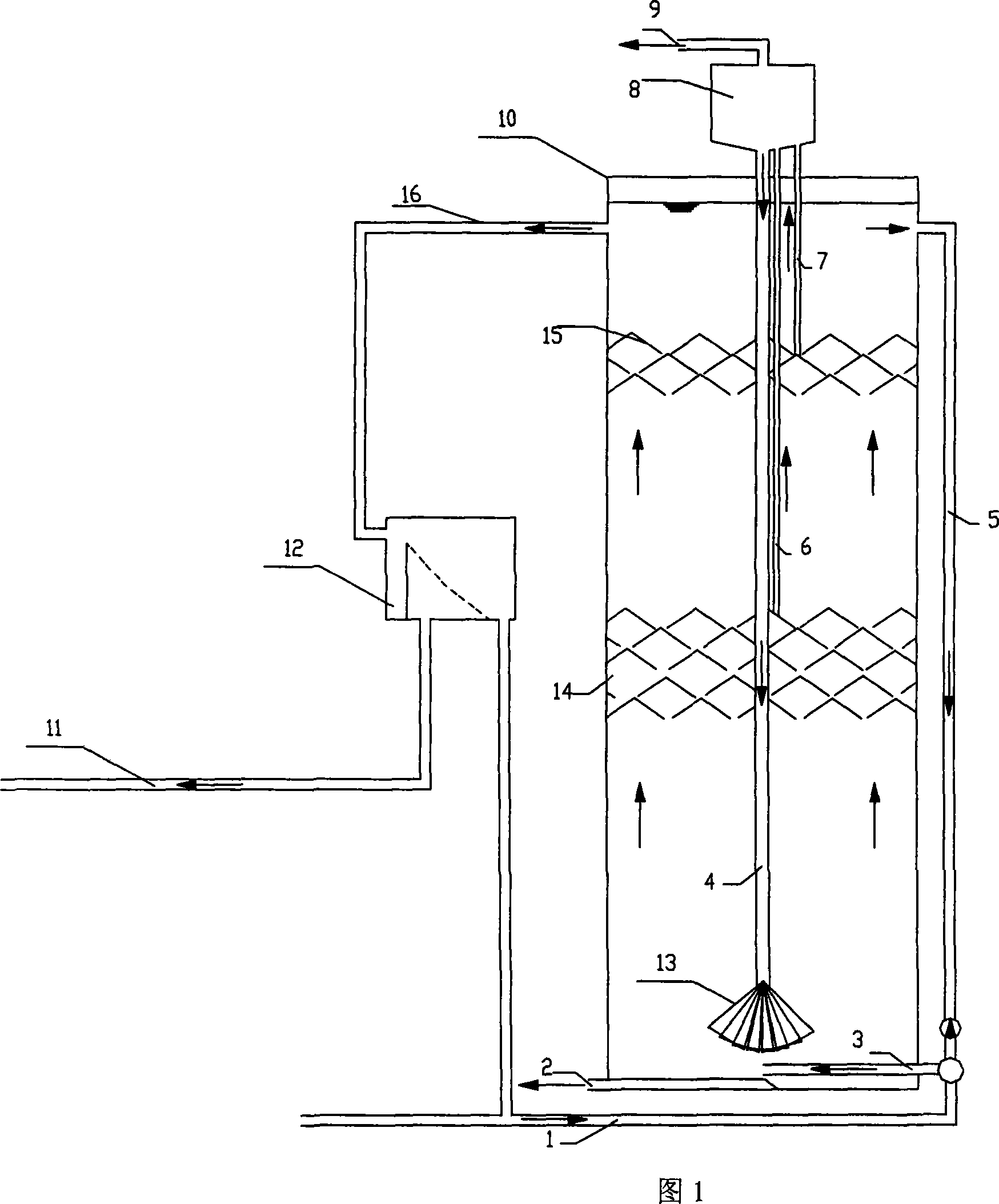

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

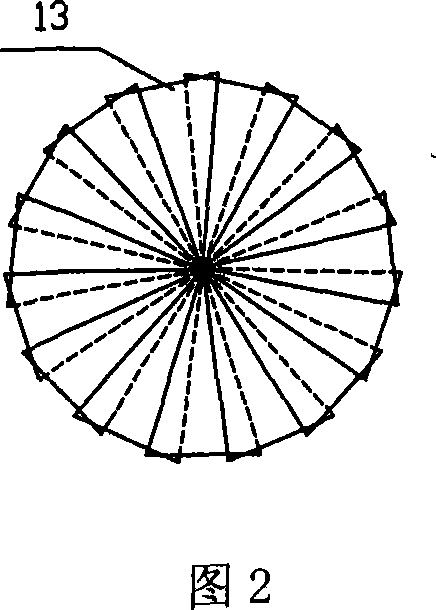

[0026] In FIG. 1 , a water distribution pipe 3 and a mud discharge pipe 2 are provided in the lower part of the multi-load anaerobic reactor tank body 10 , and the water distribution pipe 3 communicates with the water inlet pipe 1 . The first layer of three-phase separator 14 and the second layer of three-phase separator 15 inside the multi-load anaerobic reactor tank body 10 are provided with a steam-water separator 8 at the top, which communicates with the internal circulation pipe 4, and the end of the internal circulation pipe 4 A spiral water distributor 13 is provided. The steam-water separator 8 communicates with one end of the biogas riser I6 and biogas riser II7 respectively, the other end of the biogas riser I6 is located at the first layer of three-phase separator 14, and the other end of the biogas riser II7 is located at the second layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com