Refrigerator

A technology for a refrigerator and a storage room, which is applied in the field of refrigerators, can solve the problems of the compressor 50 not functioning, the discharge piping is brittle, and the compression cannot be performed, and achieves the effects of reducing the radius of the switch track, suppressing abnormal collisions, and reducing angular momentum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

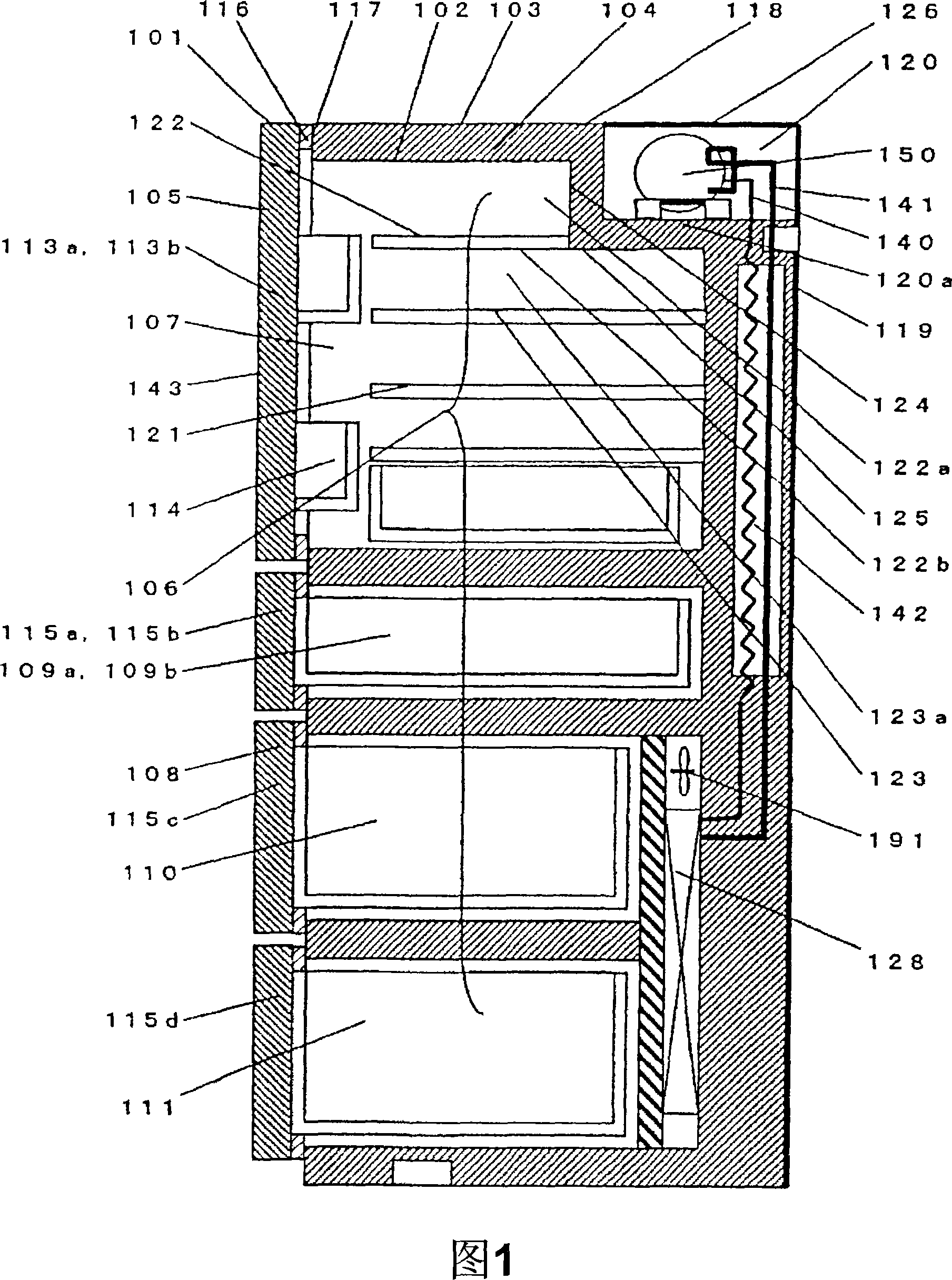

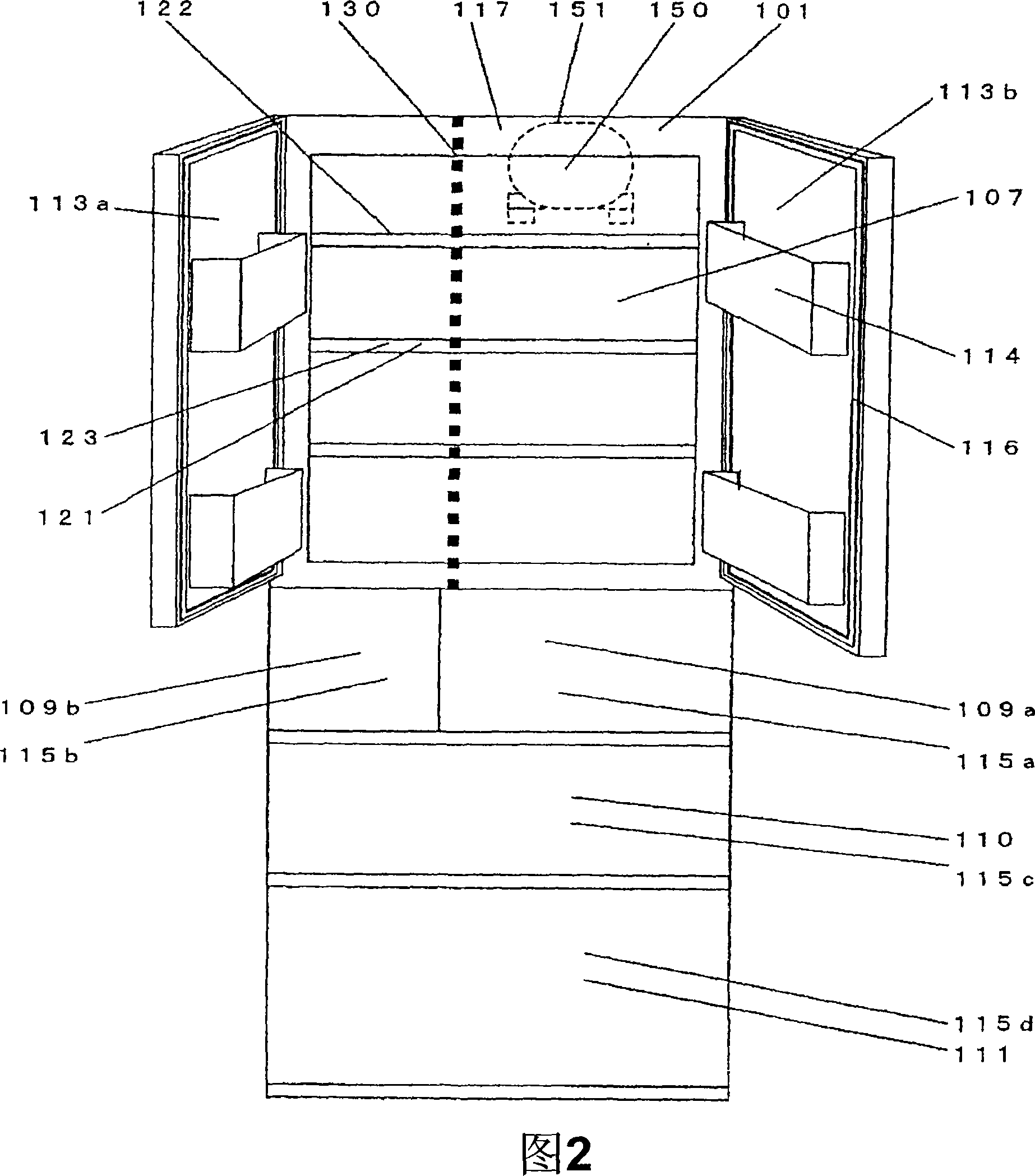

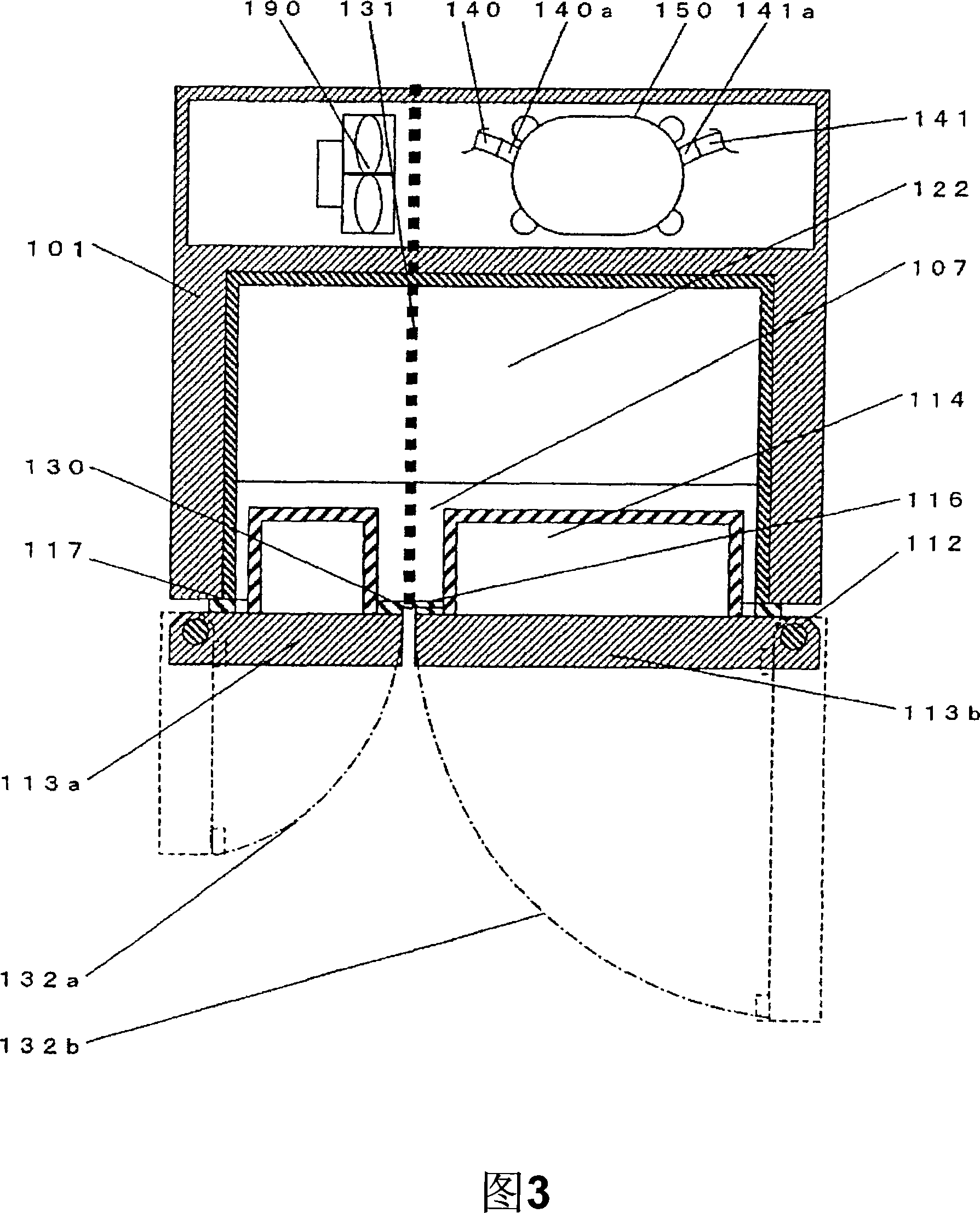

[0124] Fig. 1 is a structural sectional view of a refrigerator according to Embodiment 1 of the present invention, Fig. 2 is a front view of the refrigerator according to the same embodiment, and Fig. 3 is a view from above of the refrigerator according to the same embodiment. Figure 4 is a longitudinal sectional view of the compressor seen from the back of the refrigerator according to the same embodiment, and Figure 5 is a view from the top of the refrigerator in the same embodiment 6 is a schematic diagram for explaining the operation of the compressor when the revolving door related to the same embodiment is closed.

[0125] Next, Embodiment 1 of the present invention will be described with reference to FIGS. 1 to 6 .

[0126] In Fig. 1 to Fig. 6, the refrigerator has a compressor 150 connected in a ring shape, a discharge pipe 140 connected to the compressor 150, a condenser (not shown), and a pressure reducer built in the box body 101. A refrigerating cycle constituted ...

Embodiment approach 2

[0174] 7 is a structural sectional view of a refrigerator according to Embodiment 2 of the present invention, FIG. 8 is a front view of the refrigerator according to the same embodiment, and FIG. 9 is a view from above of the refrigerator according to the same embodiment. 10 is a schematic cross-sectional view of the opening and closing trajectory of the revolving door seen from the lateral direction of the refrigerator according to the same embodiment.

[0175] Next, Embodiment 2 will be described based on FIGS. 7 , 8 , 9 and 10 . The same structures as those in Embodiment 1 are given the same reference numerals, and detailed descriptions thereof are omitted.

[0176] In FIGS. 7 to 10 , the refrigerator includes a compressor 150 , a discharge pipe 140 connected to the compressor 150 , and a condenser (not shown). Inside the box body 201 are built-in a capillary tube 142 connected in a ring as a pressure reducer, a drier (not shown) for removing moisture, an evaporator (128) ...

Embodiment approach 3

[0189] Fig. 11 is a structural sectional view of the refrigerator according to Embodiment 3 of the present invention, Fig. 12 is a front view of the refrigerator according to the same embodiment, and Fig. 13 is a view from above of the refrigerator according to the same embodiment. Fig. 14 is a schematic sectional view of the opening and closing trajectory of the revolving door seen from the lateral direction of the refrigerator according to the same embodiment.

[0190]Next, Embodiment 3 will be described based on FIG. 11 , FIG. 12 , FIG. 13 and FIG. 14 . The same symbols are assigned to the same structures as in Embodiment 1. FIG.

[0191] In FIGS. 11 to 14 , the refrigerator includes a compressor 150 , a discharge pipe 140 connected to the compressor 150 , a condenser (not shown), and a capillary 142 as a pressure reducer. In addition, a refrigerating cycle in which a drier (not shown) for removing moisture, an evaporator 128 with an internal fan 191 arranged nearby, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com