Image inspection device and image inspection method using the image inspection device

An image inspection and image technology, which is applied in the direction of measuring devices, instruments, semiconductor/solid-state device testing/measurement, etc., can solve problems such as inability to perform inspections, and achieve the effect of preventing light halos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

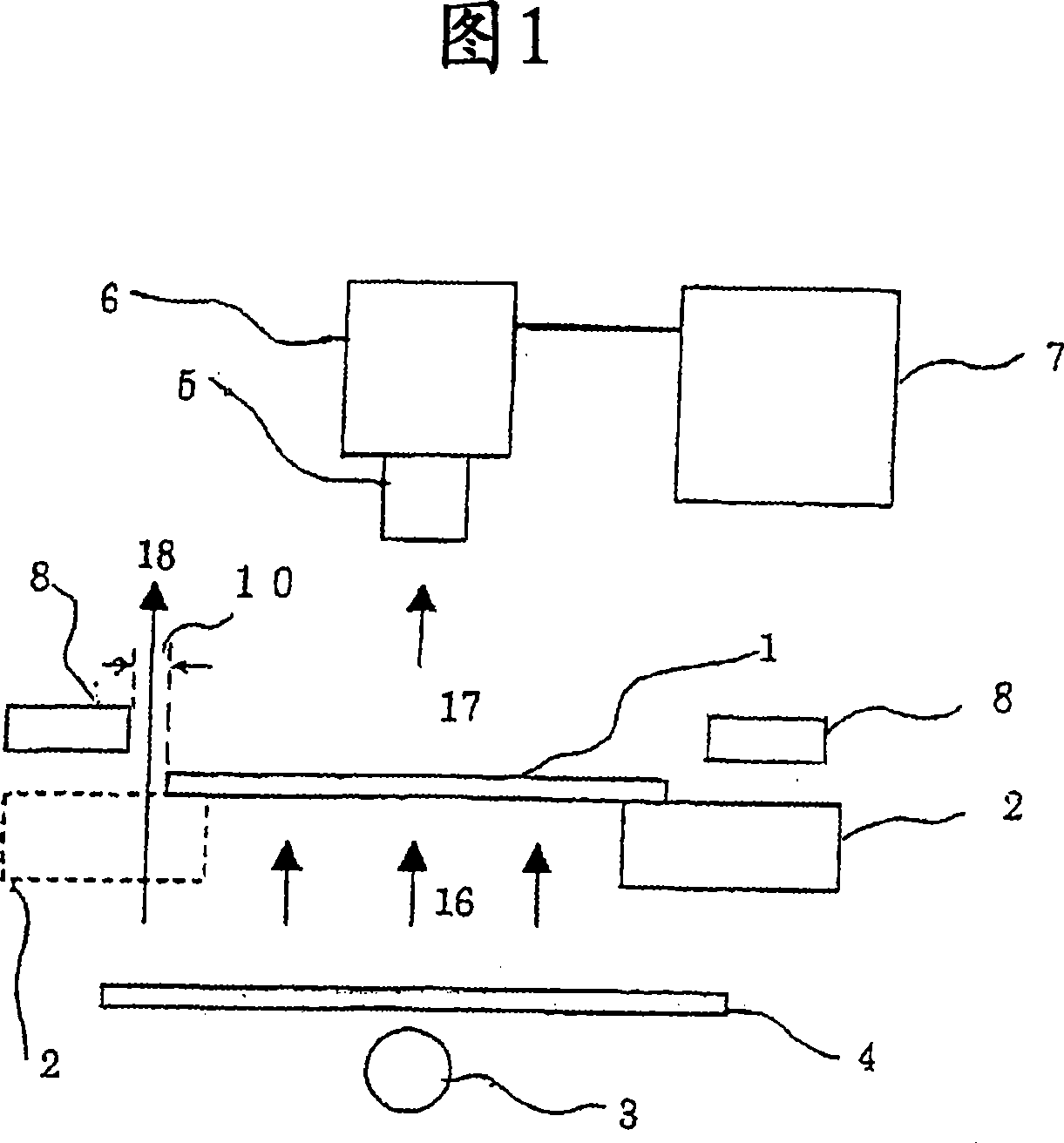

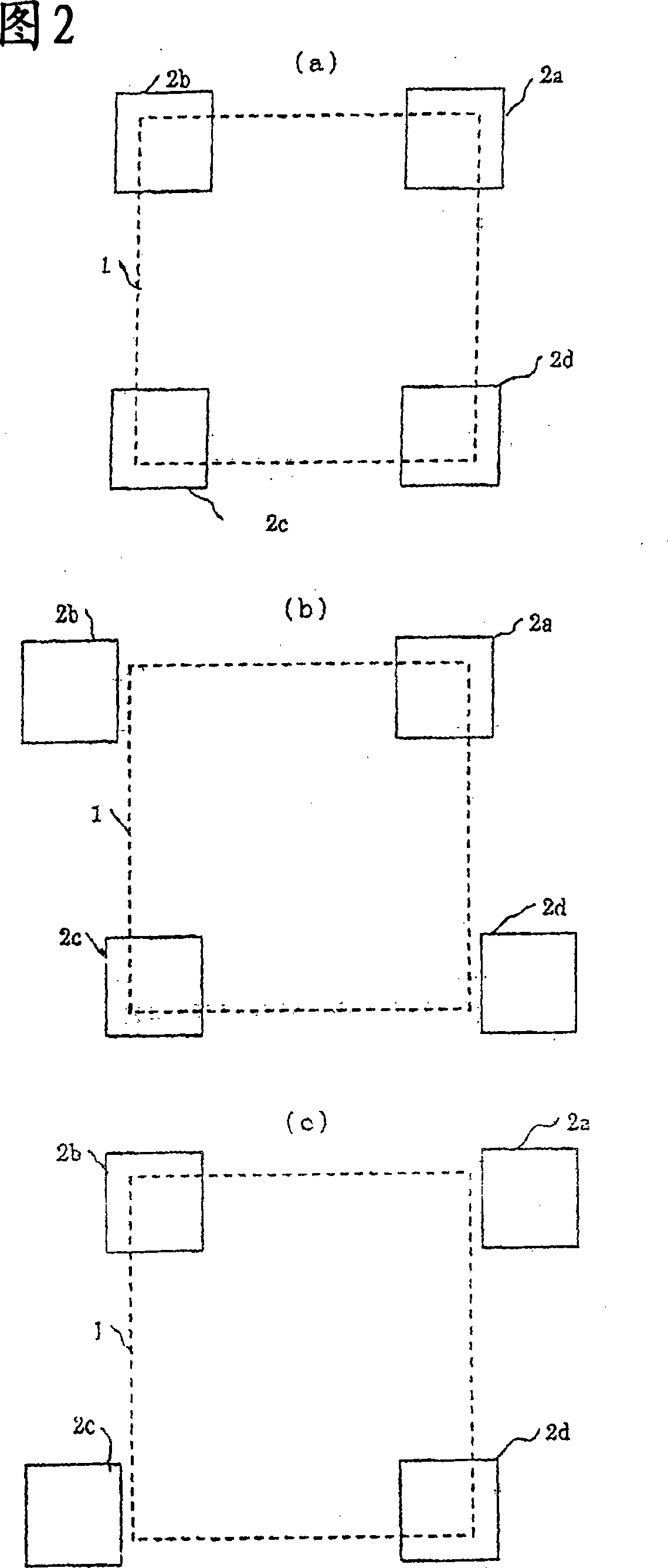

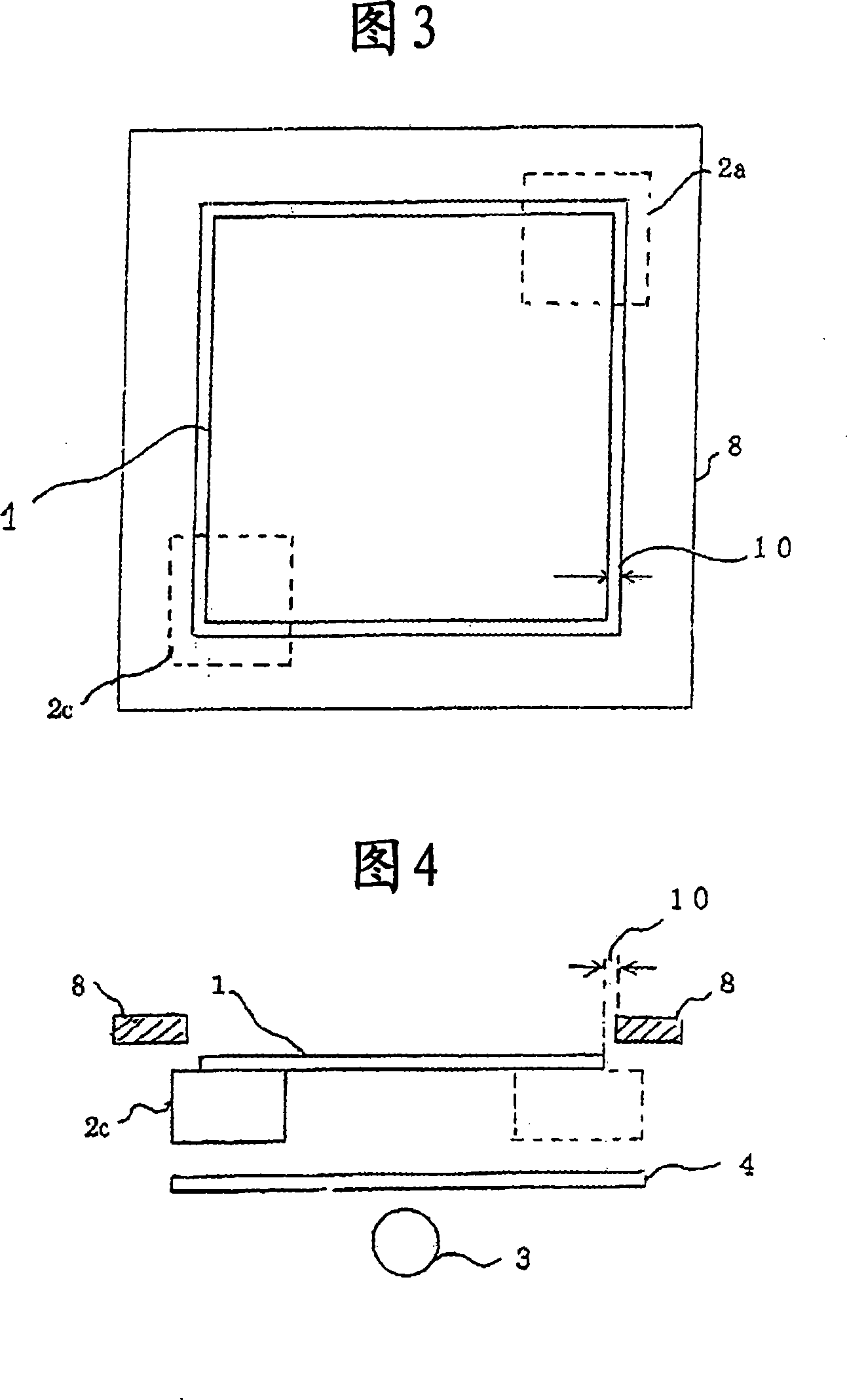

[0045] FIG. 1 is a configuration diagram showing Embodiment 1 of the present invention. In the figure, a holding table 2 holding a semiconductor wafer 1 (referred to as an inspection object holding mechanism) is provided below a semiconductor wafer 1 (an inspection object) that transmits infrared light. Here, the case where the semiconductor wafer 1 is quadrangular will be described. An infrared light source 3 is disposed below the semiconductor wafer 1 , and a plate of an infrared light diffuser 4 for diffusing infrared light is provided above the infrared light source 3 . Here, the infrared light diffuser 4 refers to a member having a function of uniformly diffusing infrared light, such as a translucent or frosted glass plate. For illustration, the infrared cursor emitted from the infrared light diffuser 4 is referenced 16 . The infrared light transmitted through the semiconductor wafer 1 is designated by reference numeral 17 . Above the semiconductor wafer 1, a camera 6 ...

Embodiment approach 2

[0059] In FIG. 1 of Embodiment 1, the mask 8 is shown as a plate-shaped member having a constant thickness. However, as shown in FIG. 6 , since the end face of the plate of the mask 8 is located at a position visible from the camera 6, the light emitted from the translucent object 4 may be reflected there (the reflected light is shown as 98 ) and may be emitted. into the camera. In order to solve this problem, as shown in FIG. 7 , a non-reflective mask 80 having a structure in which the end face is set as a sharp end portion 80a that is sharpened into a thin and sharp shape and has an inclined portion 80b such that No unwanted light is reflected in the direction of the semiconductor wafer 1 and the infrared camera 6 . Since the sharp end 80a is extremely thin, it will not be captured by the camera. In addition, since unnecessary reflected light is prevented from reaching the camera side by the inclined portion 80b, a better image can be obtained, and more stable crack inspec...

Embodiment approach 3

[0061] In Embodiment 1 and Embodiment 2, the example in which the infrared light diffuser 4 is installed horizontally was shown, but as shown in FIG. Infrared light diffuser4. By setting at a predetermined angle, dust or fragments of semiconductor wafers, etc. will not accumulate on the infrared light diffuser 4, thereby preventing dust and fragments accumulated on the translucent object 4 from being captured by the infrared camera 6. In this way, it is possible to eliminate erroneous confirmation of cracks and perform more stable crack inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com