Rotating-disk testing classifier

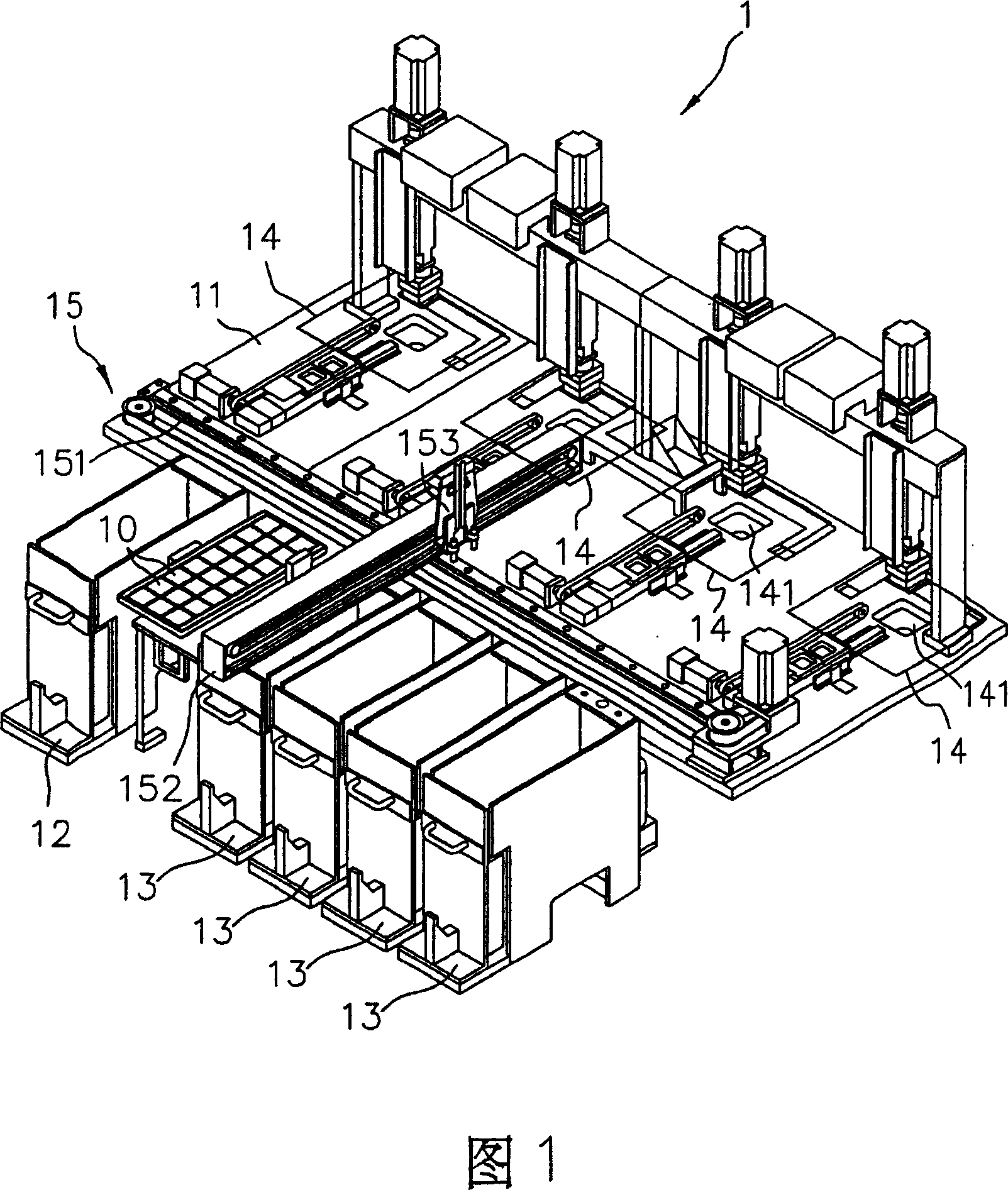

A sorting device and a rotary table type technology, which is applied in the field of rotary table test sorting devices, and can solve the problems of time-consuming, inconvenient replacement operation, and prolonged time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

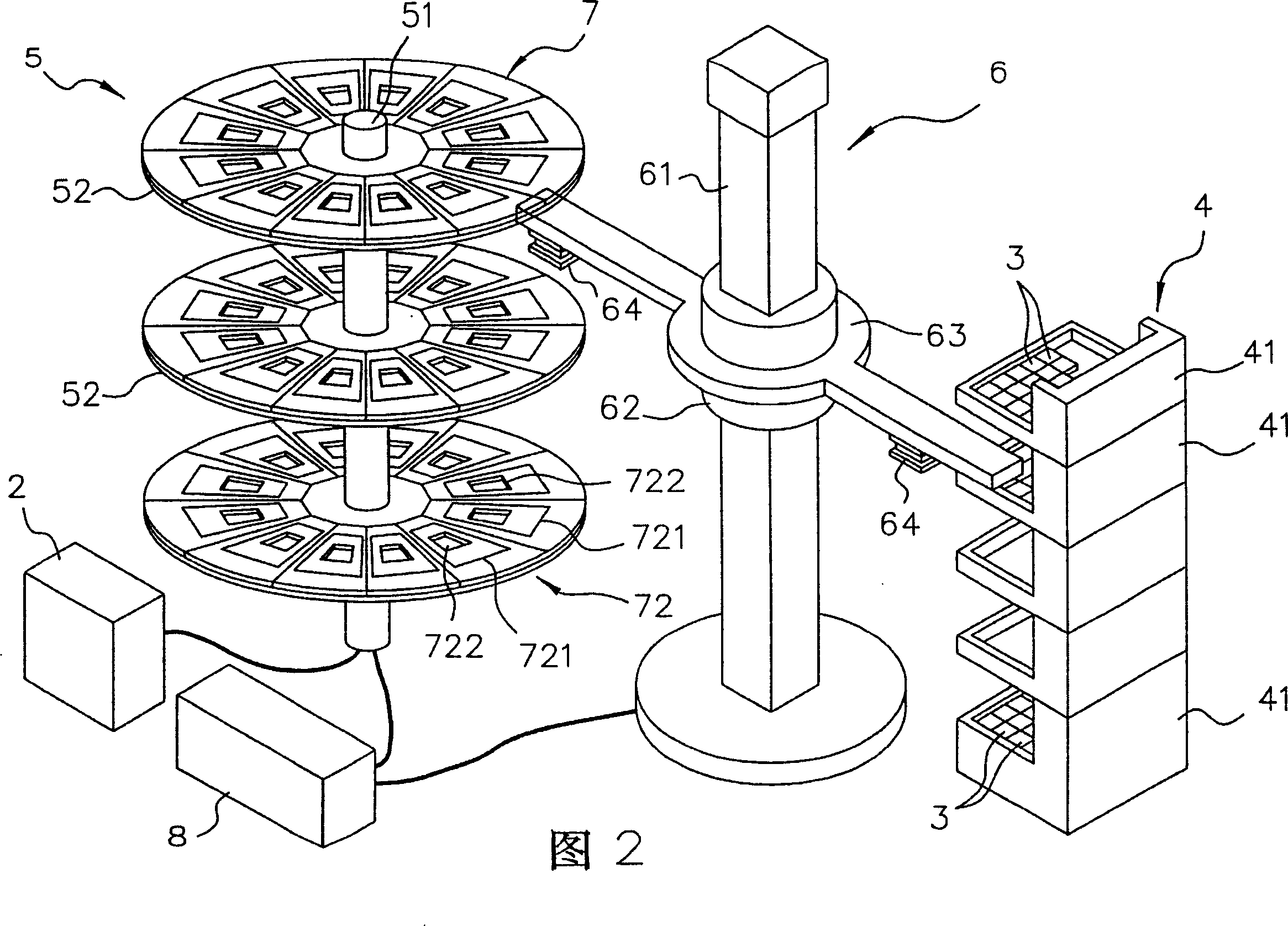

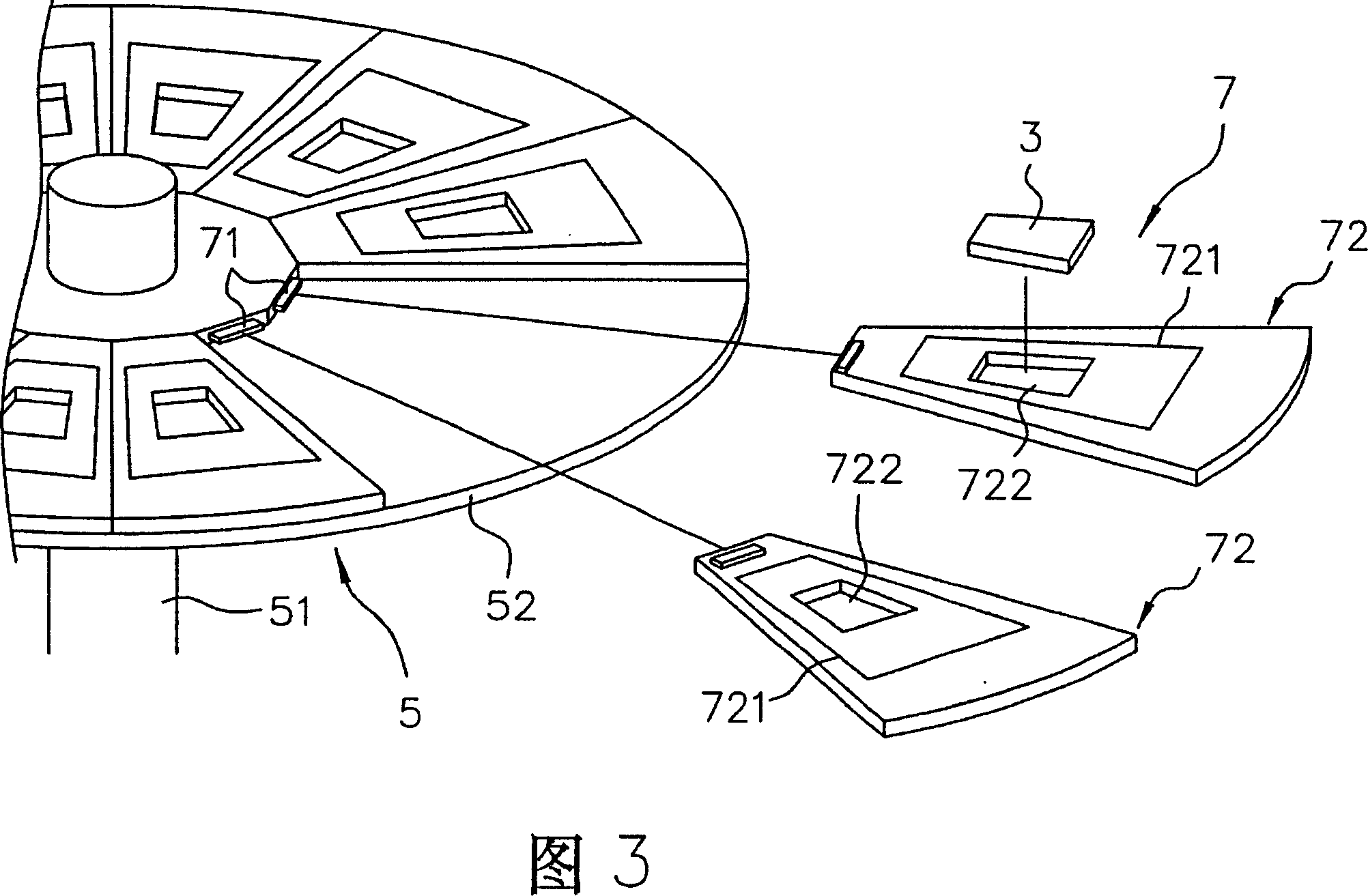

[0021] The carousel type testing and sorting device of the present invention will be described in detail below through preferred embodiments and accompanying drawings. Before the present invention is described in detail, it is noted that in the following description, similar elements are denoted by the same numerals.

[0022] As shown in FIG. 2 , the first preferred embodiment of the turntable testing and sorting device of the present invention is electrically connected to a tester (Tester) 2 and is suitable for testing several semiconductor package components 3 . The test equipment 2 is mainly capable of performing electrical tests and characteristic analysis on the semiconductor package components 3. The turntable type test and sorting device includes a material placement unit 4, a turret unit 5, a material removal unit 6, a A test interface unit 7 and a controller 8 .

[0023] The material placement unit 4 has five stacked magazines 41 stacked up and down, and the magazine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com