Use of rice hull and artifical woods

A rice husk and wood technology, applied in the field of new materials, can solve the waste of rice husk resources and other problems, and achieve the effects of no pollution in performance, protection of the ecological environment, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

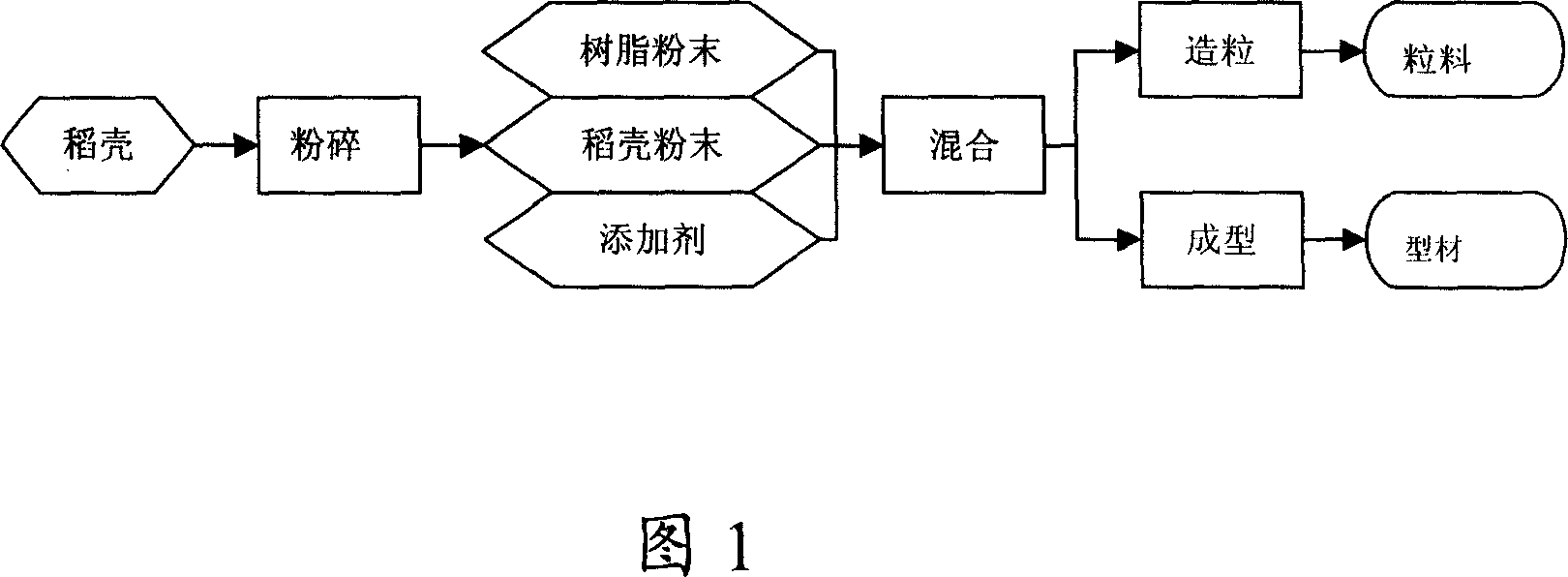

Method used

Image

Examples

Embodiment 1

[0027] The mass ratio of the artificial wood used to make the floor is: 30-50% of rice husk powder, 45-65% of PVC powder, 5% of additives such as dyeing agent, flame retardant, anti-aging agent, and mold release agent.

Embodiment 2

[0029] The mass ratio of the artificial wood used to make door and window profiles is: 20-40% of rice husk powder, 55-75% of PVC powder, 5% of additives such as dyeing agent, flame retardant, anti-aging agent, and mold release agent.

Embodiment 3

[0031] The mass ratio for making artificial wood is: 40-60% of rice husk powder, 35-55% of PVC powder, and 5% of additives such as dyeing agent, flame retardant, antiaging agent, and mold release agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com