Method for designing mould cavity

A design method and mold technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of long mold manufacturing cycle and many mold cavity trials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

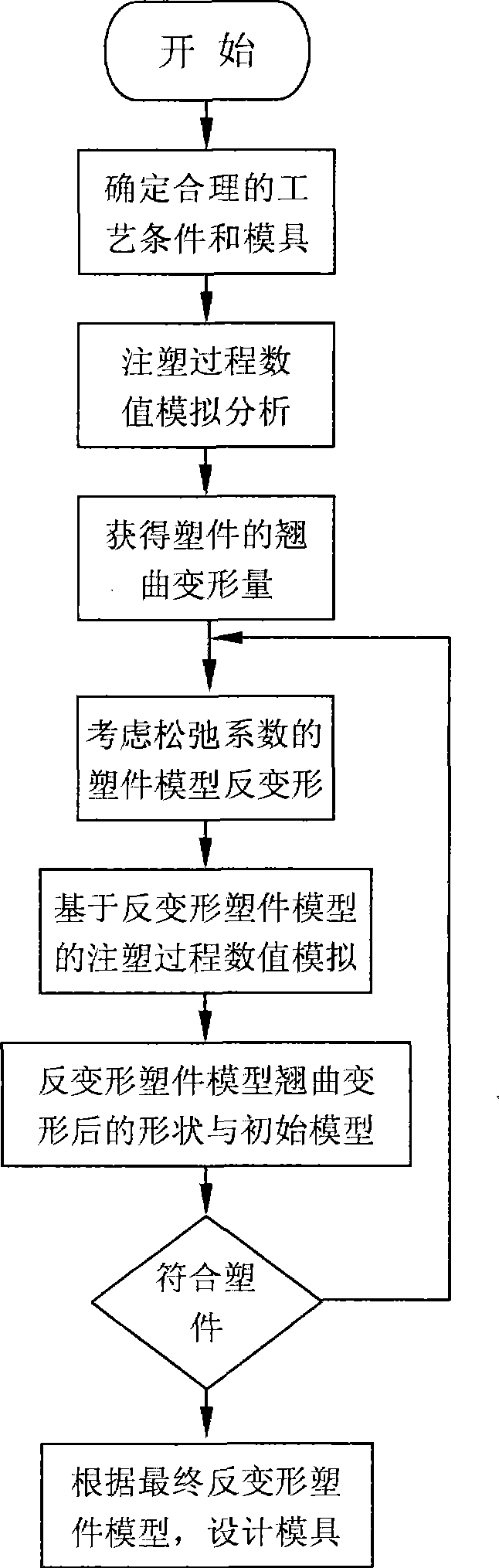

[0008] The principle diagram of the present invention is as shown in Figure 1, and the mold cavity design method of the present invention includes

[0009] Include the following steps:

[0010] 1) According to the plastic injection molding process theory, practical experience and numerical simulation, etc., determine the reasonable injection molding process conditions and mold structure;

[0011] 2) Use numerical simulation software to divide the initial model of plastic parts into unit mesh nodes, and perform numerical simulation analysis of the injection molding process;

[0012] 3) Obtain the warpage deformation of each unit node position of the plastic part;

[0013] 4) After multiplying the warping deformation of the nodes by a relaxation coefficient less than or equal to 1, different reverse deformation treatments are performed on different positions of the original model of the plastic part;

[0014] 5) For the anti-deformation-treated plastic part model, under the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com