Dredging mud direct dike building method

A mud, direct technology, applied in dikes, coastline protection, dams, etc., can solve the problems of low shear strength, large amount of sand and gravel, long cycle, etc., and achieve the effect of good stability, fast construction progress and shortened construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

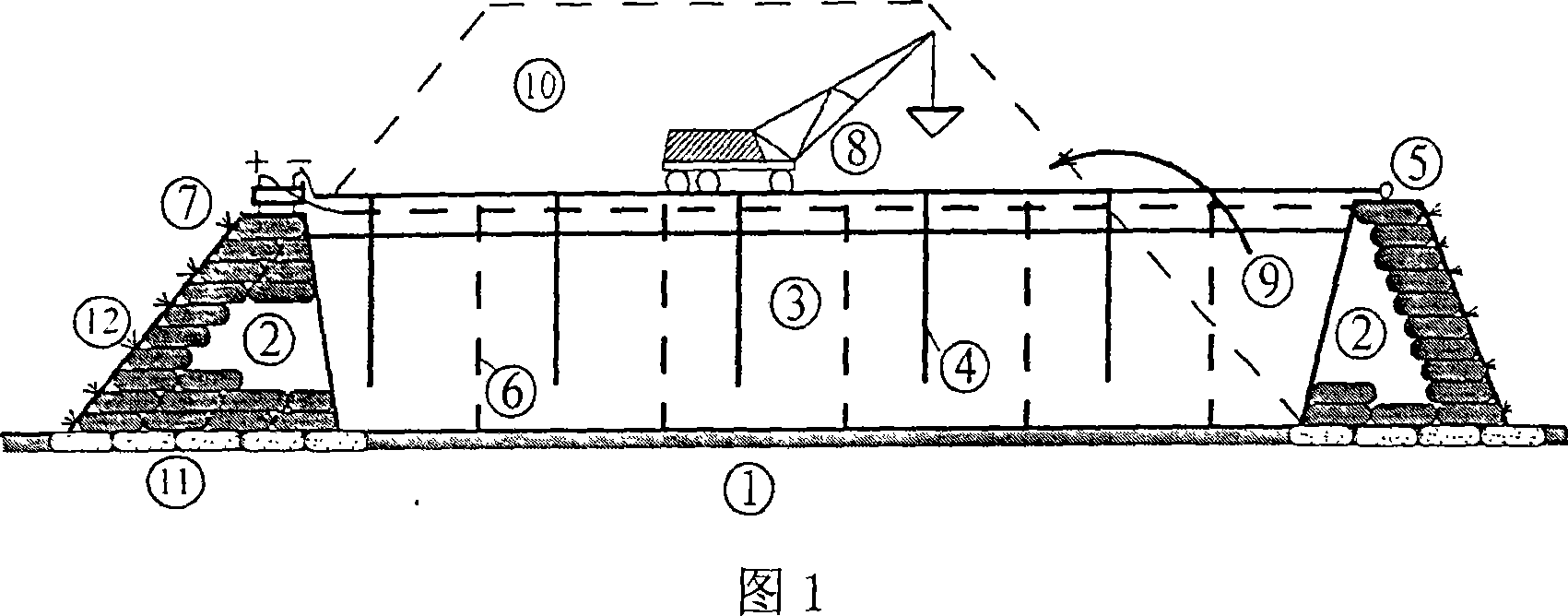

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] As shown in Figure 1.

[0026] A construction method using dredging mud to directly build embankments, which consists of the following steps:

[0027] 1. Earthbag cofferdam construction

[0028] 1) Lay 1 to 2 layers of geotechnical bags 11 filled with medium-coarse sand or coarse aggregates on the site where the cofferdam is designed. The size of the geotechnical bag is 1m×1m×0.3m (length×width×thickness). Polypropylene mixed with anti-aging agent, the weight of the geotechnical bag is ≥100g / m 3 , Woven bags with a warp and weft density ≥ 75×44, and a rope for hoisting is attached to the outside of the geotechnical bag. The soil bags are connected to each other with hoisting ropes to form a whole.

[0029] 2) After the laying of each layer of soil bags, use a medium or small flat plate vibrator to roll it 3-4 times to make the soil bags flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com