Precision determination method for angle between optical axis and mechanical axis of optical system

An optical system and mechanical axis technology, which is applied to measuring devices, optical devices, instruments, etc., can solve the problem of inability to accurately measure the angle between the optical axis and the mechanical axis, and achieve the effect of easy implementation and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

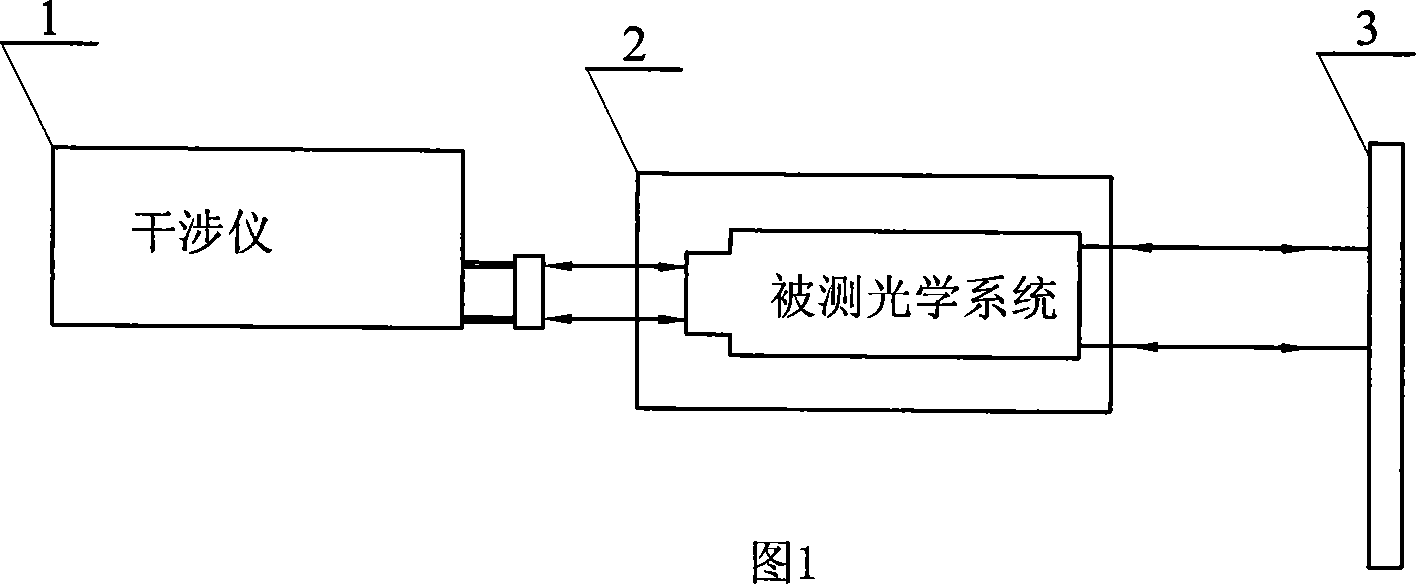

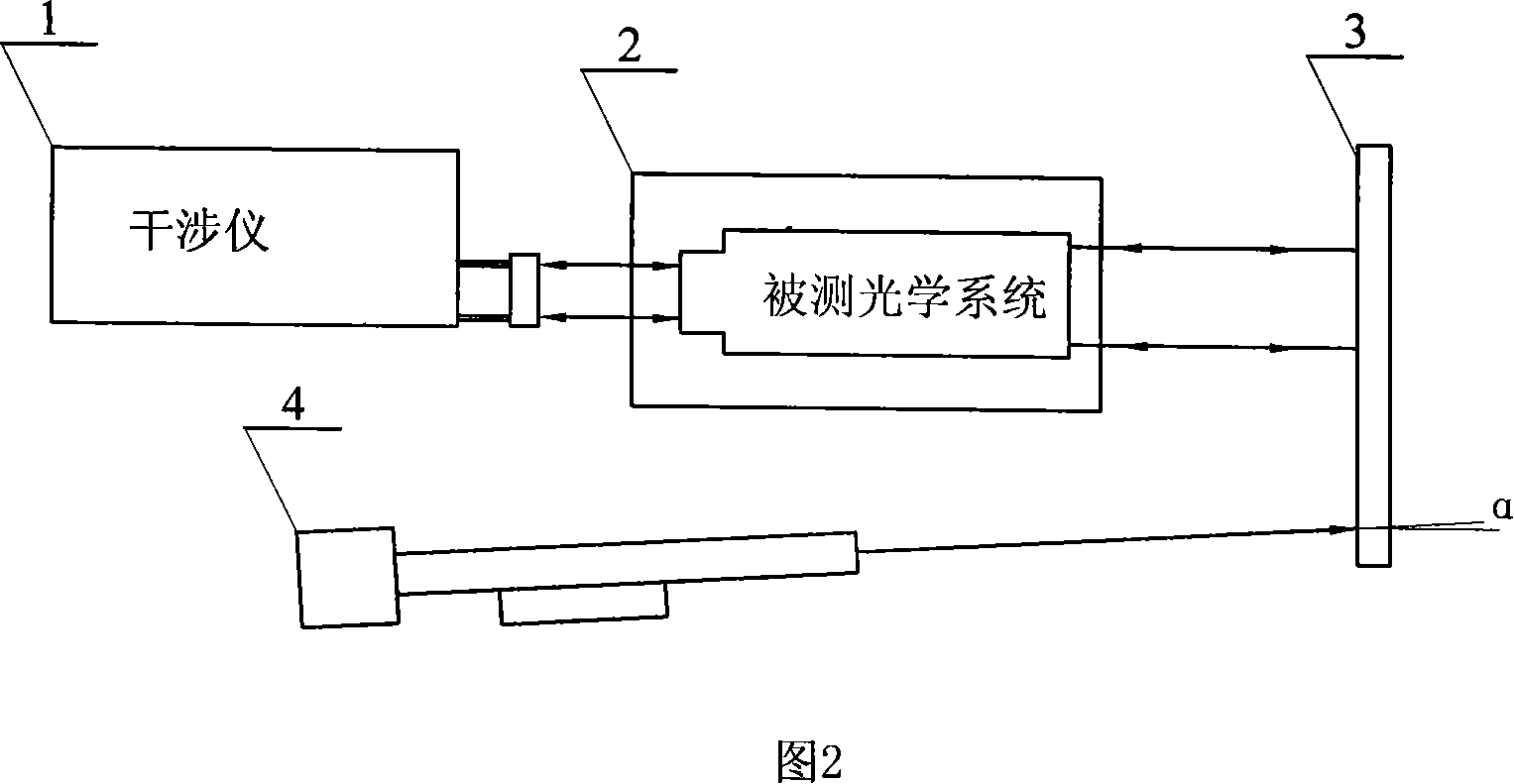

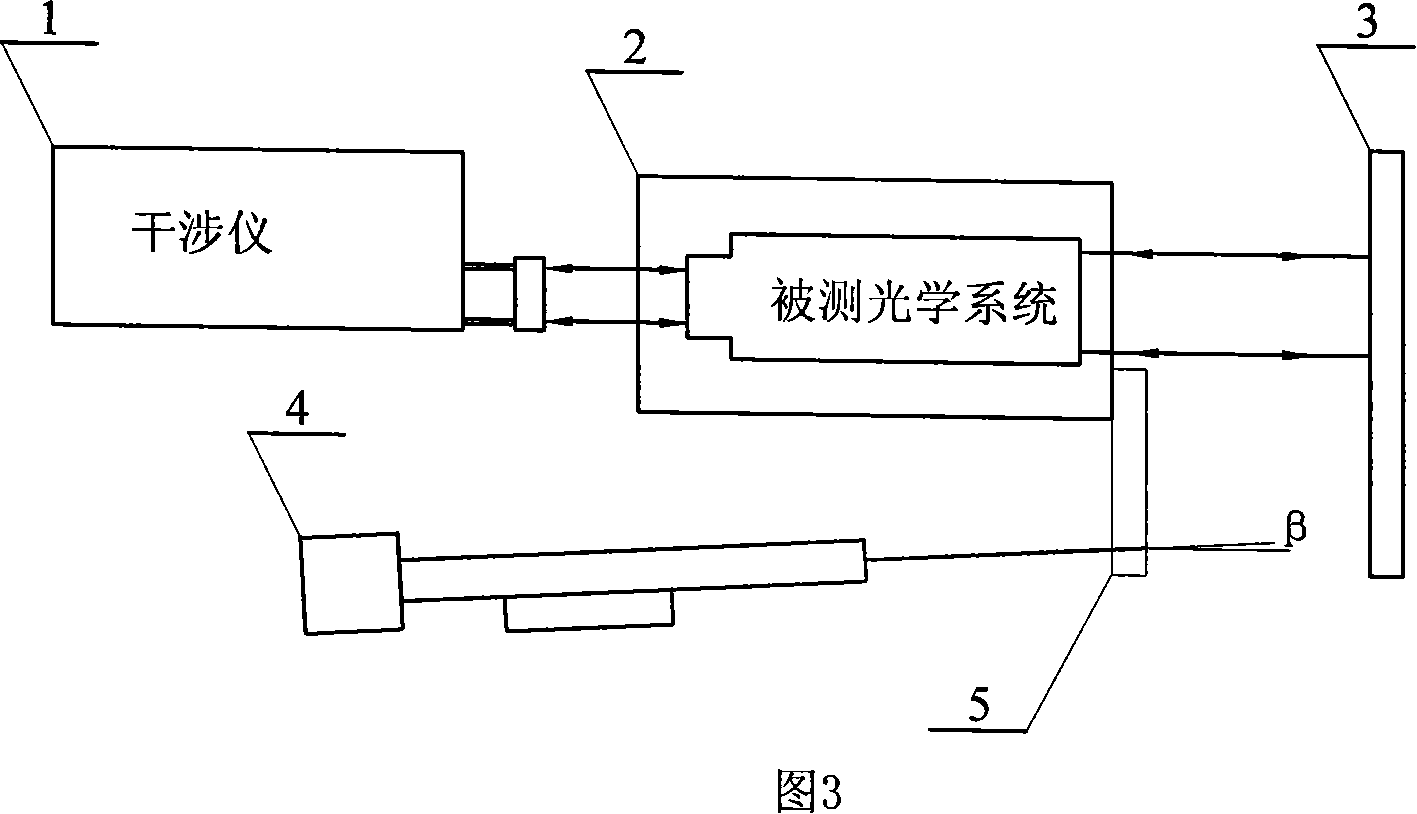

[0011] Specific embodiment one: illustrate this embodiment in conjunction with Fig. 1, Fig. 2, Fig. 3, the method step of this specific embodiment is:

[0012] The first step: the laser beam emitted by the interferometer 1 enters the high-precision flat mirror 3 after passing through the measured optical system 2, and the laser beam is reflected by the first high-precision flat mirror 3 and enters the interferometer 1 through the measured optical system 2; Adjust the azimuth and elevation angles of the first high-precision flat mirror 3 so that the fringes of the interferometer 1 are left-right and up-down symmetrical, that is, the optical axis of the first high-precision flat mirror 3 coincides with the optical axis of the measured optical system 2;

[0013] The second step: the autocollimator 4 is arranged in front of the high-precision flat mirror 3, and the autocollimator 4 emits a laser beam to the first high-precision flat mirror 3, and the laser beam is incident on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com