Method for processing mechanical diaphram pump crank bearing bushing

A technology of crankshaft bearings and processing methods, applied to shafts and bearings, rigid supports of bearing components, mechanical equipment, etc., to achieve considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

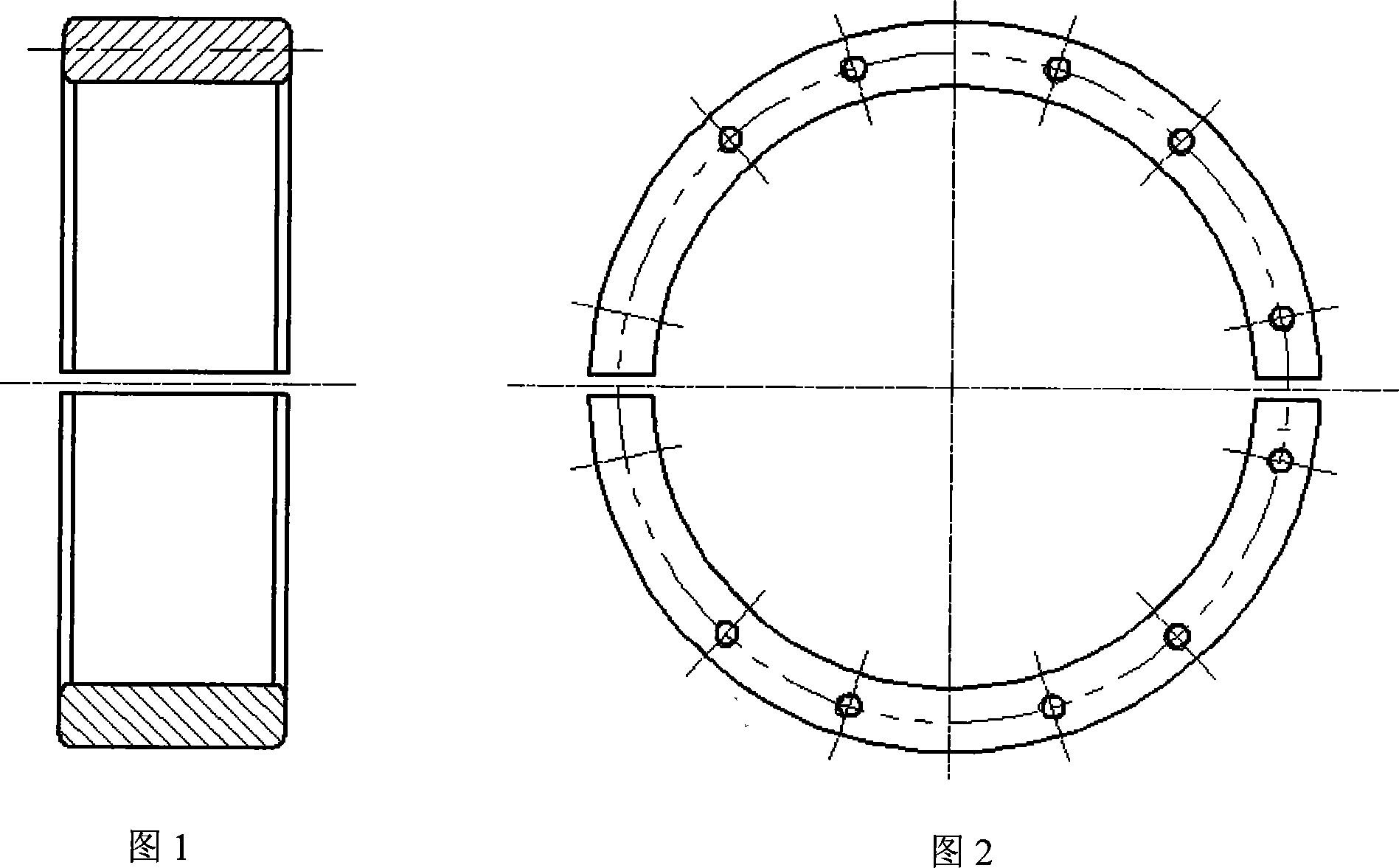

[0015] As shown in attached drawing 1, the outer dimension of the bush is φ560×φ670×220 (mm); the material of the bush is No. 45 steel, quenched and tempered; , the tolerance is -0.01 +0.03 mm; the coaxiality of the inner and outer surfaces of the bushing is not greater than 0.035mm; the roundness error of the inner and outer surfaces is not greater than 0.05mm; the verticality error of the two ends facing the inner and outer surfaces is not greater than 0.04mm; 2 ~ 4mm. After carefully analyzing the technical requirements of the product, the process is arranged according to the technical solution of the present invention, and the effect is good through verification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com