Corrugated box printing grooving and die-cut combination machine

A corrugated box and combined machine technology, used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as affecting printing color registration accuracy, and achieve the effect of increasing effective production hours, convenient operation of equipment, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

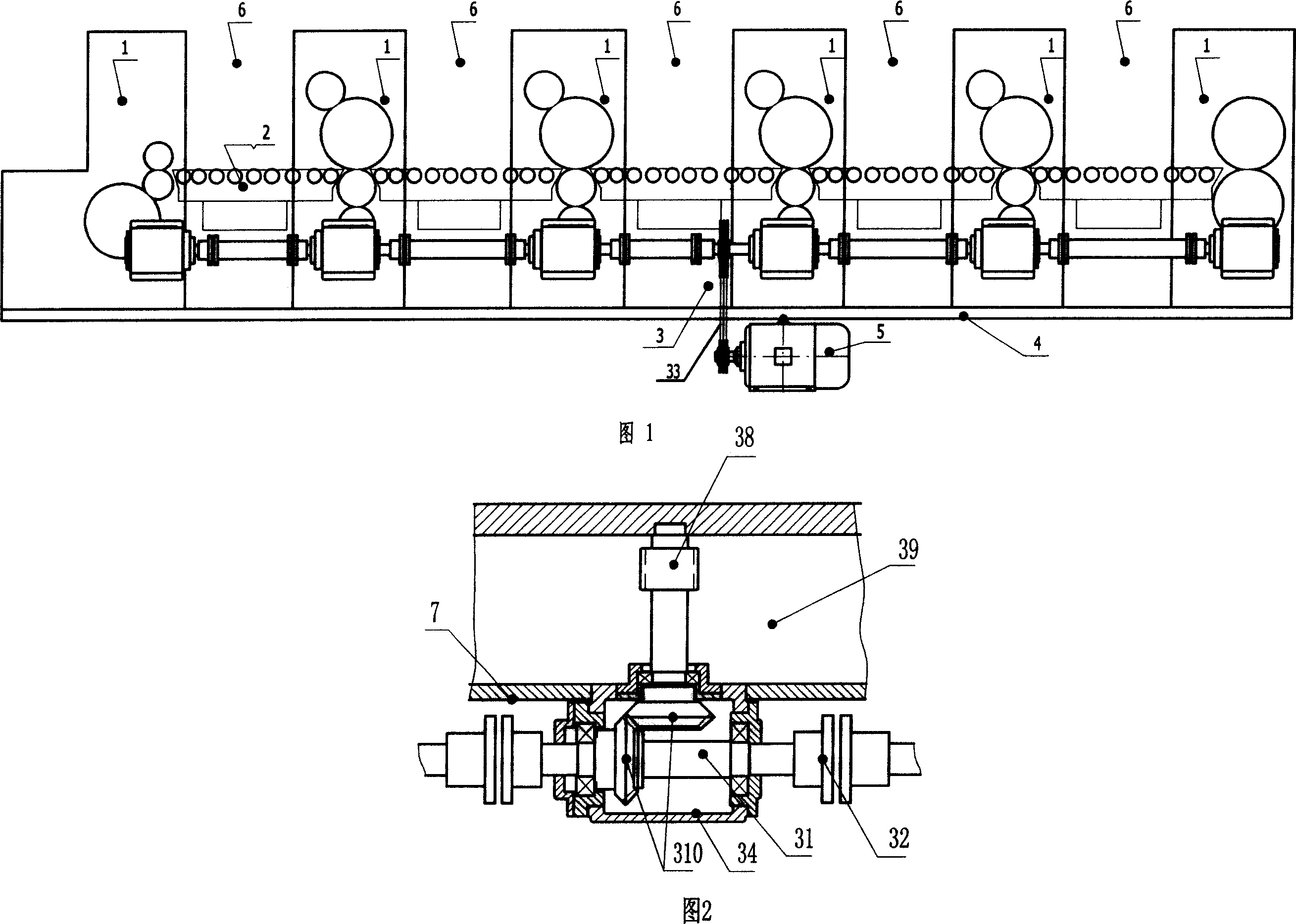

[0013] As shown in accompanying drawing 1, the preferred implementation scheme of this example is, comprises each unit unit unit 1, suction transmission mechanism 2, main shaft transmission mechanism 3, mounting bracket 4, main motor 5, and each unit unit unit unit 1 is respectively fixed on the installation On the bracket 2, there is an operation interval 6 between two adjacent unit units, and the main motor 5 is located in the middle of the entire unit unit. The device 2 also passes through the inside of each unit unit 1 .

[0014] As shown in Fig. 1 and Fig. 2, the main shaft transmission mechanism 3 includes a main shaft 31, a diaphragm coupling 32, a pulley 33, and a bevel gearbox 34. The main shaft 31 and the bevel gearbox 34 are installed on the outside of each unit unit. The motor 5 is connected to the main shaft 31 for transmission through a pulley 33 , and the unit shafts on the main shaft 31 are connected through a diaphragm coupling 32 . The bevel gear box 34 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com