Crystallized glass and method for producing crystallized glass

A technology of glass-ceramic and a manufacturing method, which is applied in the photoengraving process of the pattern surface, the manufacture of semiconductor/solid-state devices, the originals for optical mechanical processing, etc., can solve the problem of poor production efficiency and easy cracking of large-sized molded products , easy to damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] A preferable form of the glass ceramics of this invention is demonstrated. In addition, unless otherwise specified, each component is expressed in terms of oxides, and the content of each component is expressed in mass % in terms of oxides.

[0117] In this specification, the so-called "in terms of oxides" means that among the components assumed to be used as the composition components of the glass ceramics of the present invention, fluoride components, sulfate components, chloride components, and compound salts other than these are excluded. When the base glass is completely decomposed into oxides at the time of melting, the method of each component contained in the glass ceramics is described. When describing content, each component contained in glass ceramics is described with the oxide total weight converted into an oxide being 100 mass %.

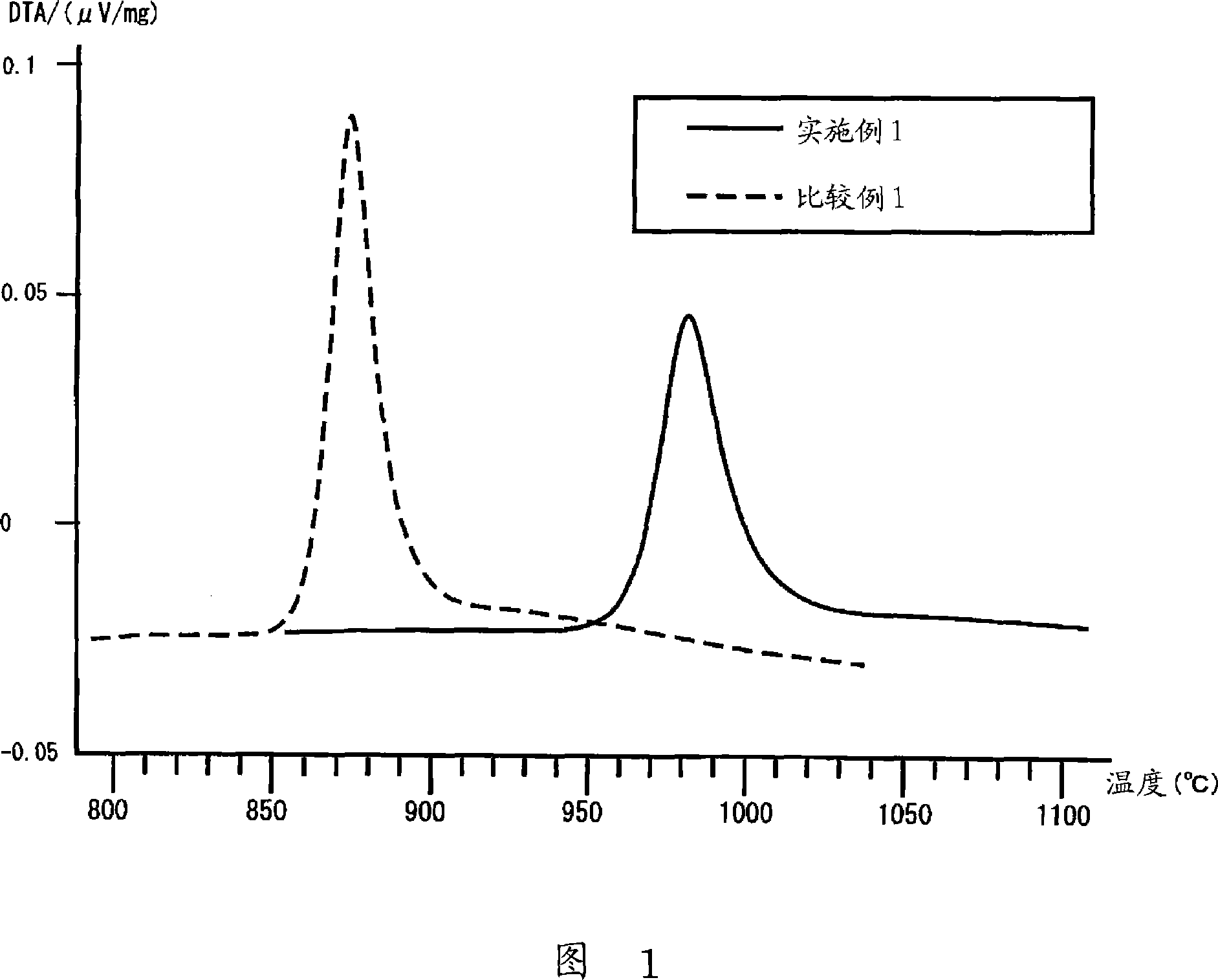

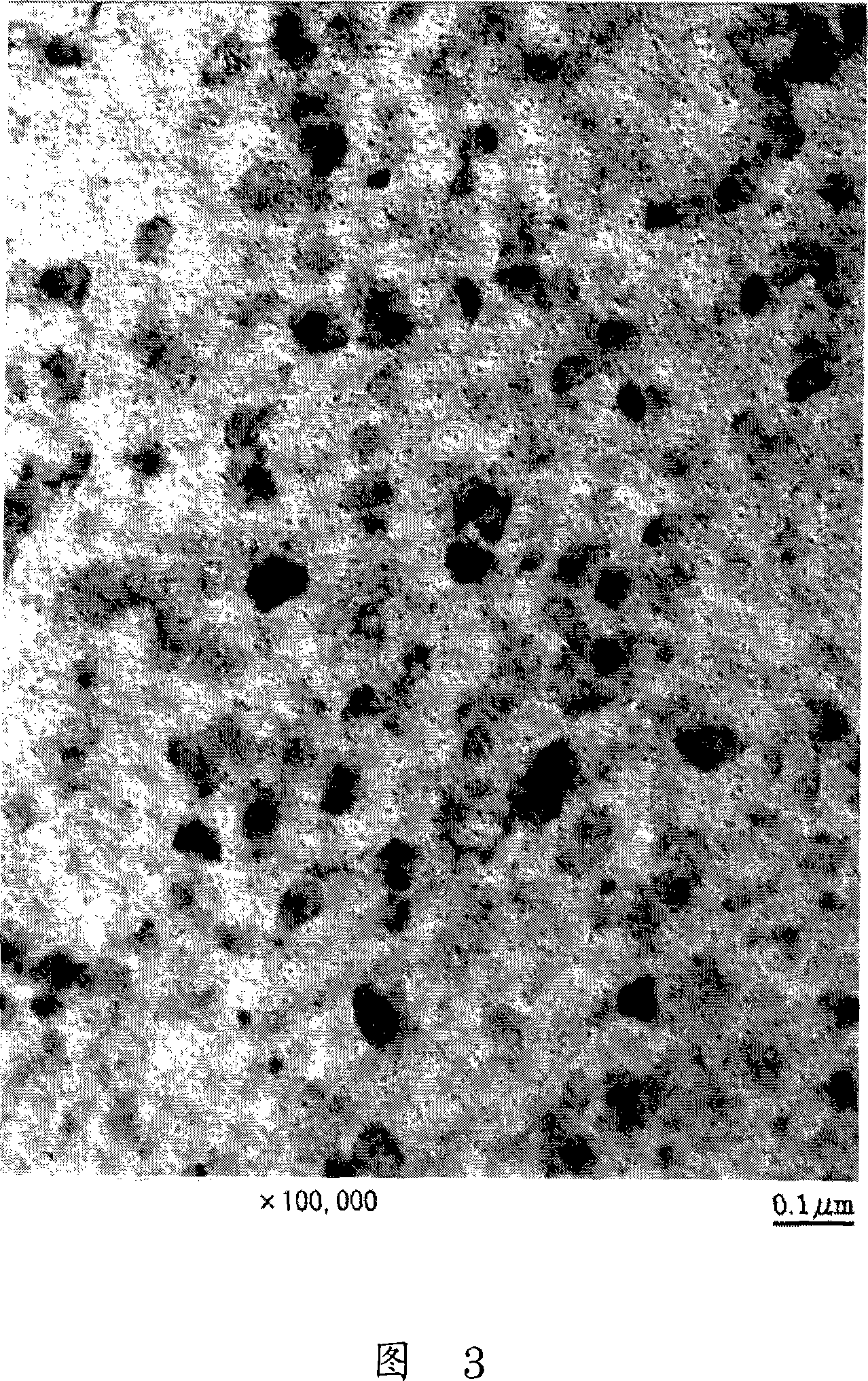

[0118] as SiO 2 -Al 2 o 3 Department or Li 2 O-Al 2 o 3 -SiO 2 One of the characteristics of glass-ceramics of the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com