Crystallized glass and method for producing crystallized glass

一种微晶玻璃、制造方法的技术,应用在图纹面的照相制版工艺、半导体/固态器件制造、用于光机械处理的原件等方向,能够解决设备维修成本变大、不现实、制造设备成本变大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

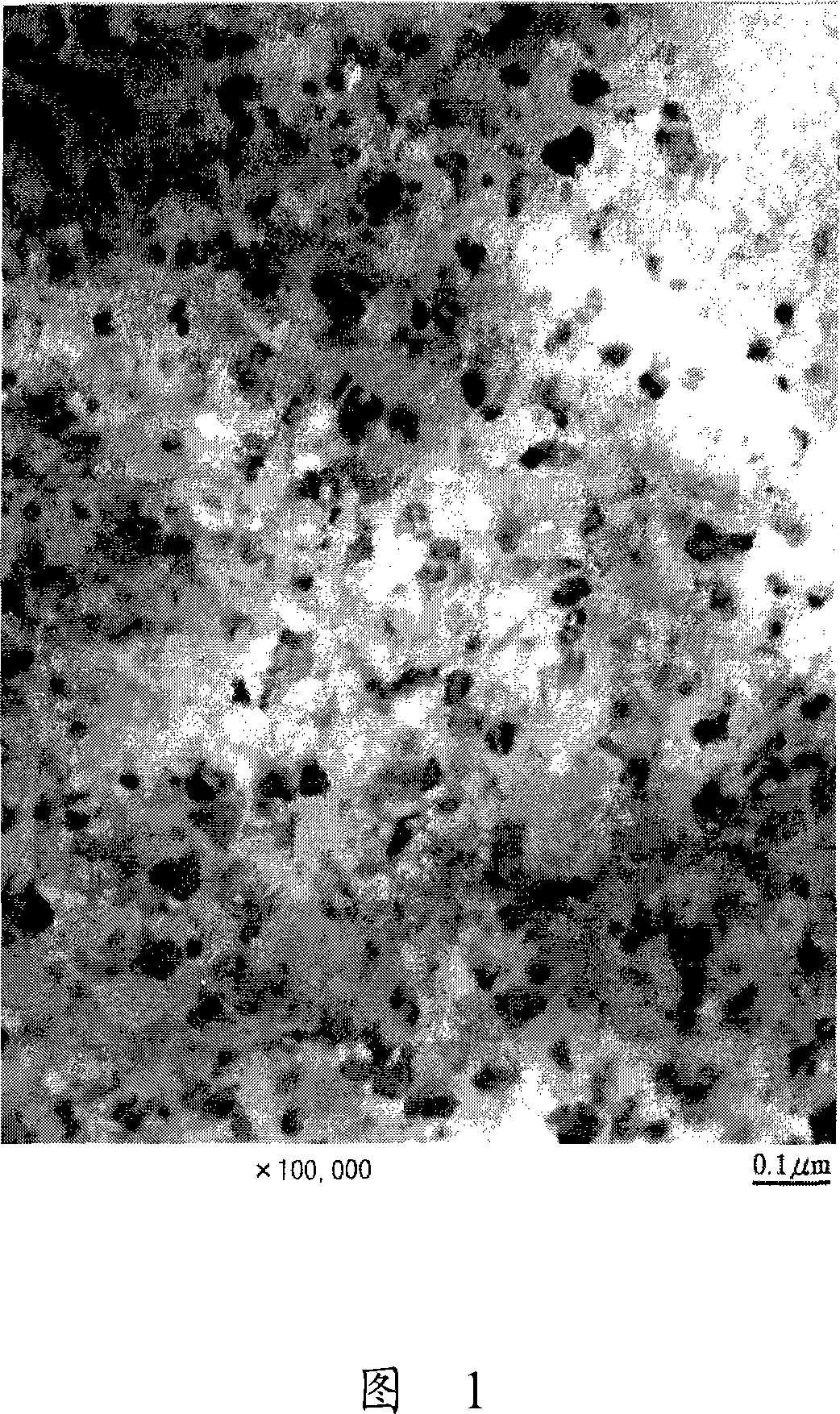

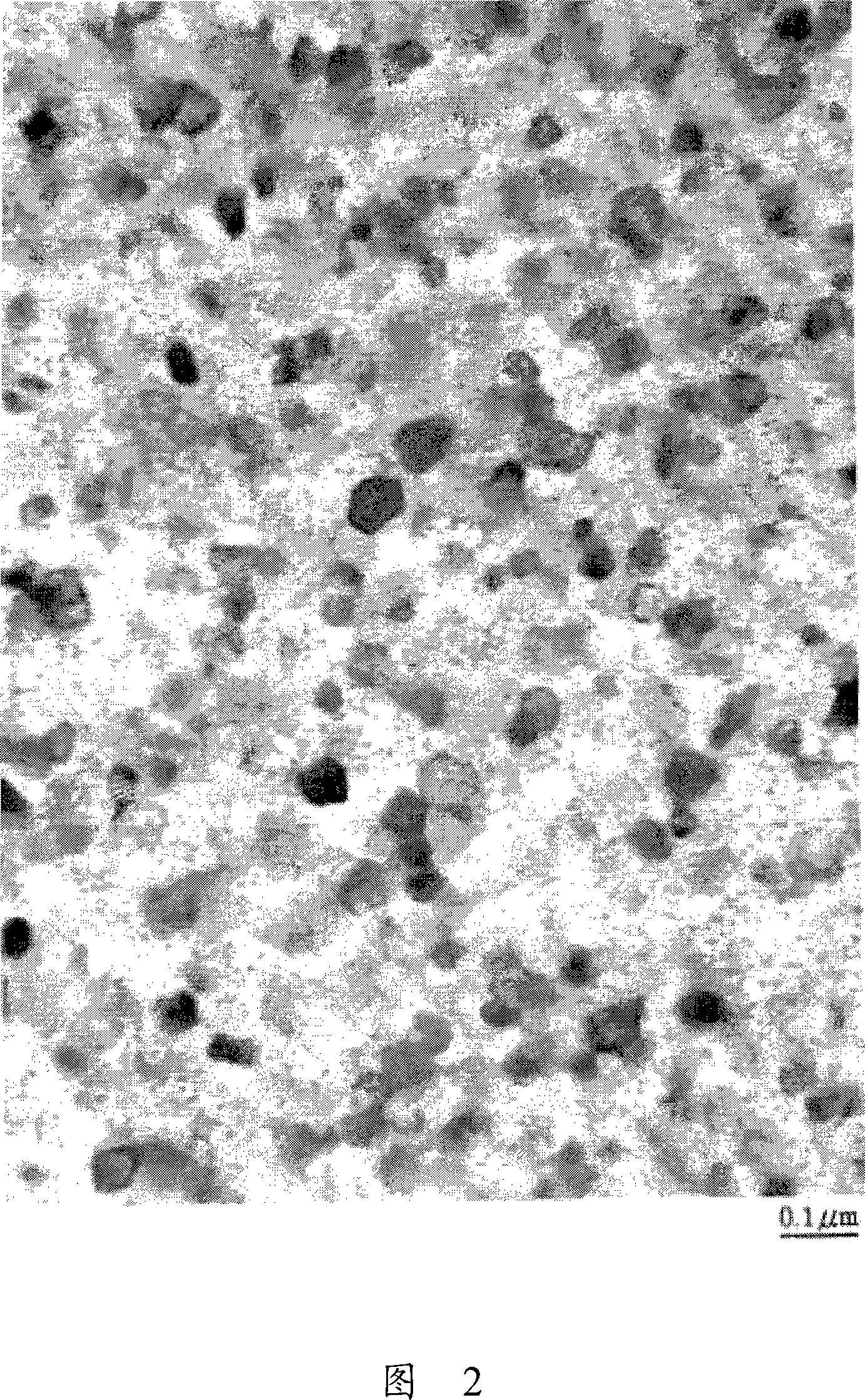

[0123] as SiO 2 -Al 2 o 3 Department or Li 2 O-Al 2 o 3 -SiO 2 One of the characteristics of glass-ceramics of the glass-ceramic system is low expansion. This low expansion can be achieved by adding SiO 2 -Al 2 o 3 Department or Li 2 O-Al 2 o 3 -SiO 2 The composition control of the glass-ceramics of the system is obtained for a specific composition. Components used in next-generation lithography technology using EUV light in semiconductor manufacturing require thermal dimensional stability, strength, thermal durability, and chemical stability, and in particular require extremely low expansion necessary for thermal dimensional stability characteristics, and has been studying the use of low expansion, the SiO 2 -Al 2 o 3 Department or Li 2 O-Al 2 o 3 -SiO 2 Glass-ceramics are used in the aforementioned components.

[0124] In addition, SiO 2 -Al 2 o 3 Department or Li 2 O-Al 2 o 3 -SiO 2 One of the characteristics of the glass-ceramics of this type is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com