Process of installing multiple-tower combination of gantry

A gantry crane and combined installation technology, which is applied in the field of ships, can solve the problems of increased structural weight, insufficient tower bearing capacity, and inability to meet actual installation and construction, and achieve the effects of increased bearing capacity, improved synchronization performance, and reduced engineering risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

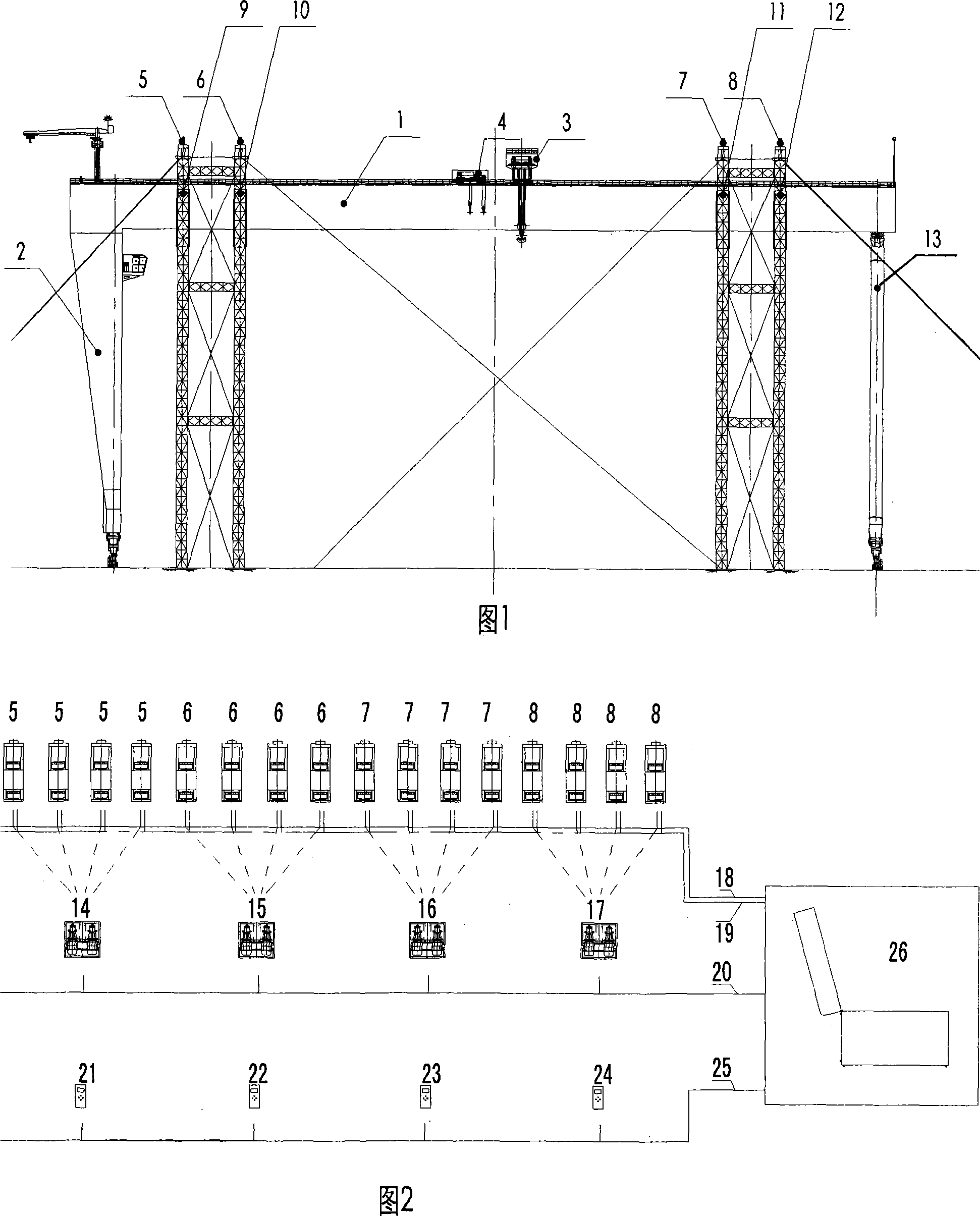

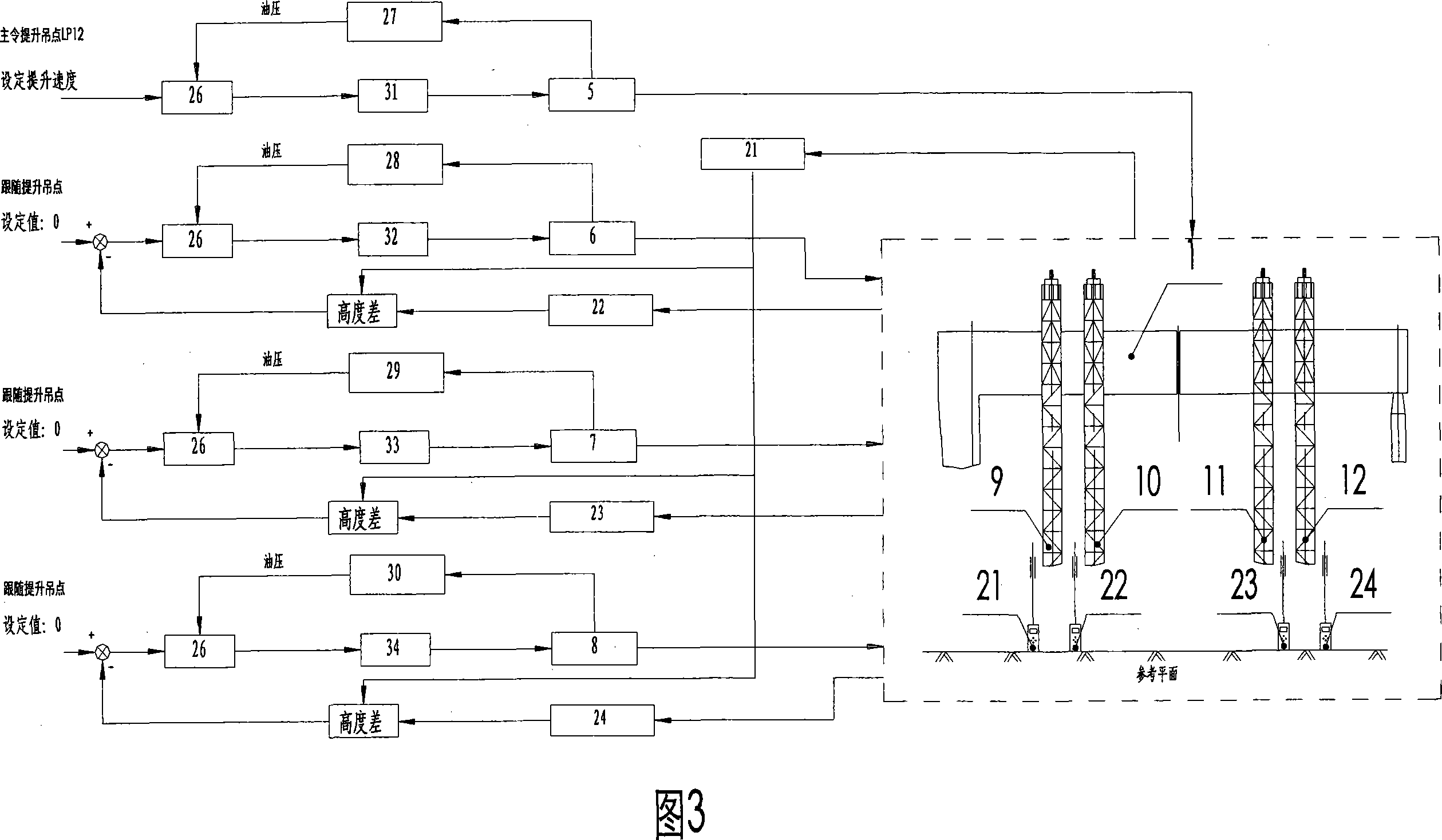

[0020] Embodiment 1: As shown in Figure 1, the lifting cylinders 5, 6, 7, 8 are respectively arranged on the tops of the masts 9, 10, 11, 12, and are respectively connected with the girder 1 of the gantry crane through steel strands, thereby forming four a lifting point. Correspondingly, a long-distance sensor 21-24 is installed under each lifting point, and each long-distance sensor 21-24 measures the height of the lifting point in real time, and transmits the measured height to the main control cabinet through the laser signal communication line 25 26. An oil pressure sensor is installed on each oil cylinder, and the oil pressure sensor measures the status signal of each oil cylinder in real time, and transmits the status signal to the main control cabinet 26 through the oil pressure communication line 18, so that the main control cabinet can accurately monitor the load data according to the collected load data in real time. Adjust the load distribution of the individual po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com