High efficient laminated graphic discharge gap device

A discharge gap, stacked technology, applied in circuits, spark gaps, electrical components, etc., can solve the problem of not determining the discharge electrode material, not explaining the spark arc suppression problem, and the uncertainty of the fixed value or value range of the grading capacitor. and other problems, to achieve the effect of controlling ignition breakdown voltage, protecting safety, and no arc leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

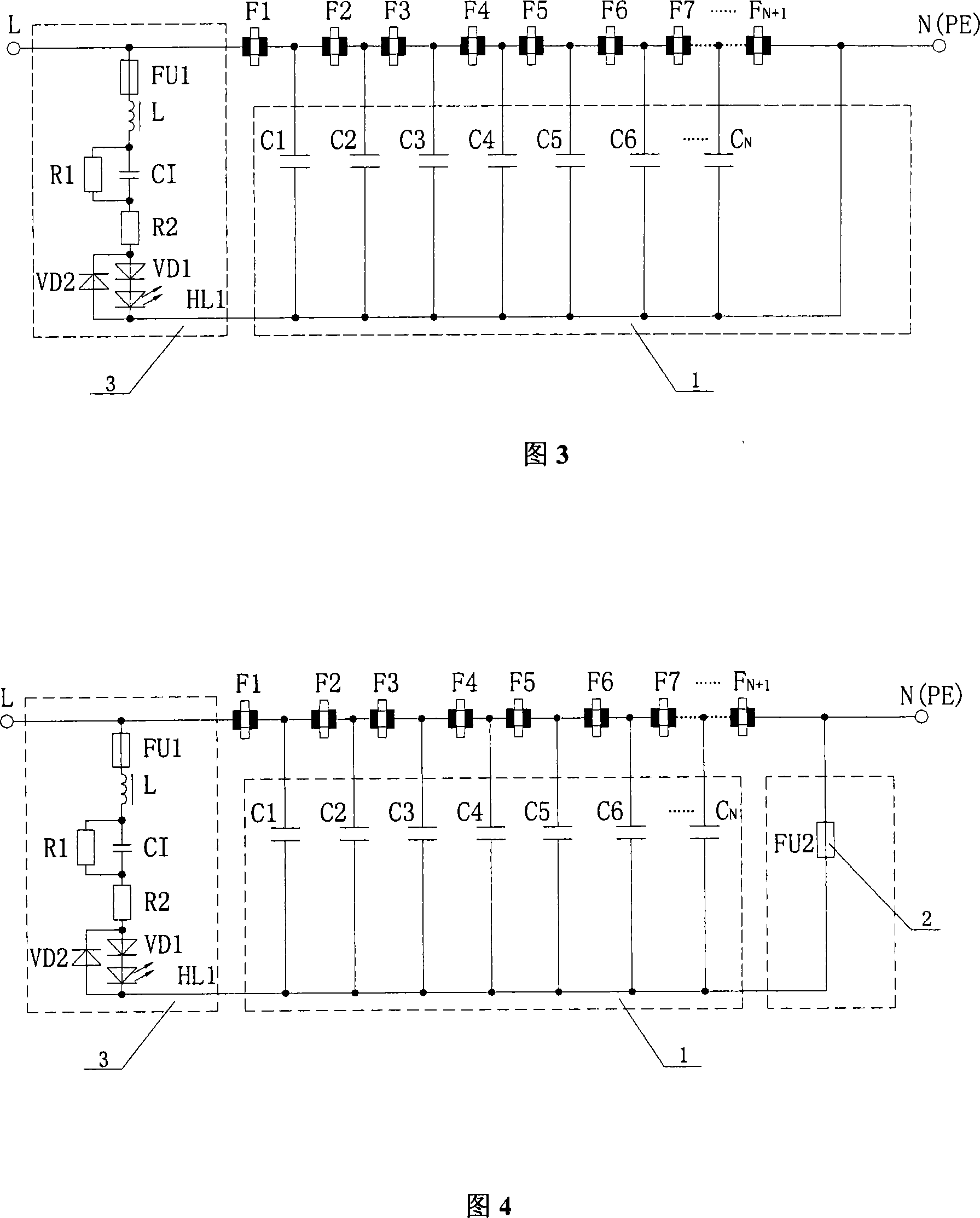

[0056] The circuit structure of the high-efficiency graphite laminated discharge gap device in this embodiment is shown in Figure 4, including eight graphite discharge gaps, a π-shaped connection capacitor group 1 composed of seven capacitors with the same capacitance value, a current fuse 2 and an indication Circuit 3. Each graphite discharge gap is connected in series, wherein, the first graphite discharge gap F 1 Connect with live wire, the last discharge gap F 8 Grounded, π-shaped connection to each capacitor C in the capacitor bank 1 、C 2 、C 3 、C 4 、C 5 、C 6 、C 7 One end is connected to the conductive part between the two graphite discharge gaps, and the other end is grounded; the end of the π-shaped connection capacitor group circuit is connected to the current fuse 2; one end of the indicating circuit is connected to the first graphite discharge gap F 1 On the connecting piece with the live wire L, the other end is grounded. The structure of the indicating circ...

Embodiment 2

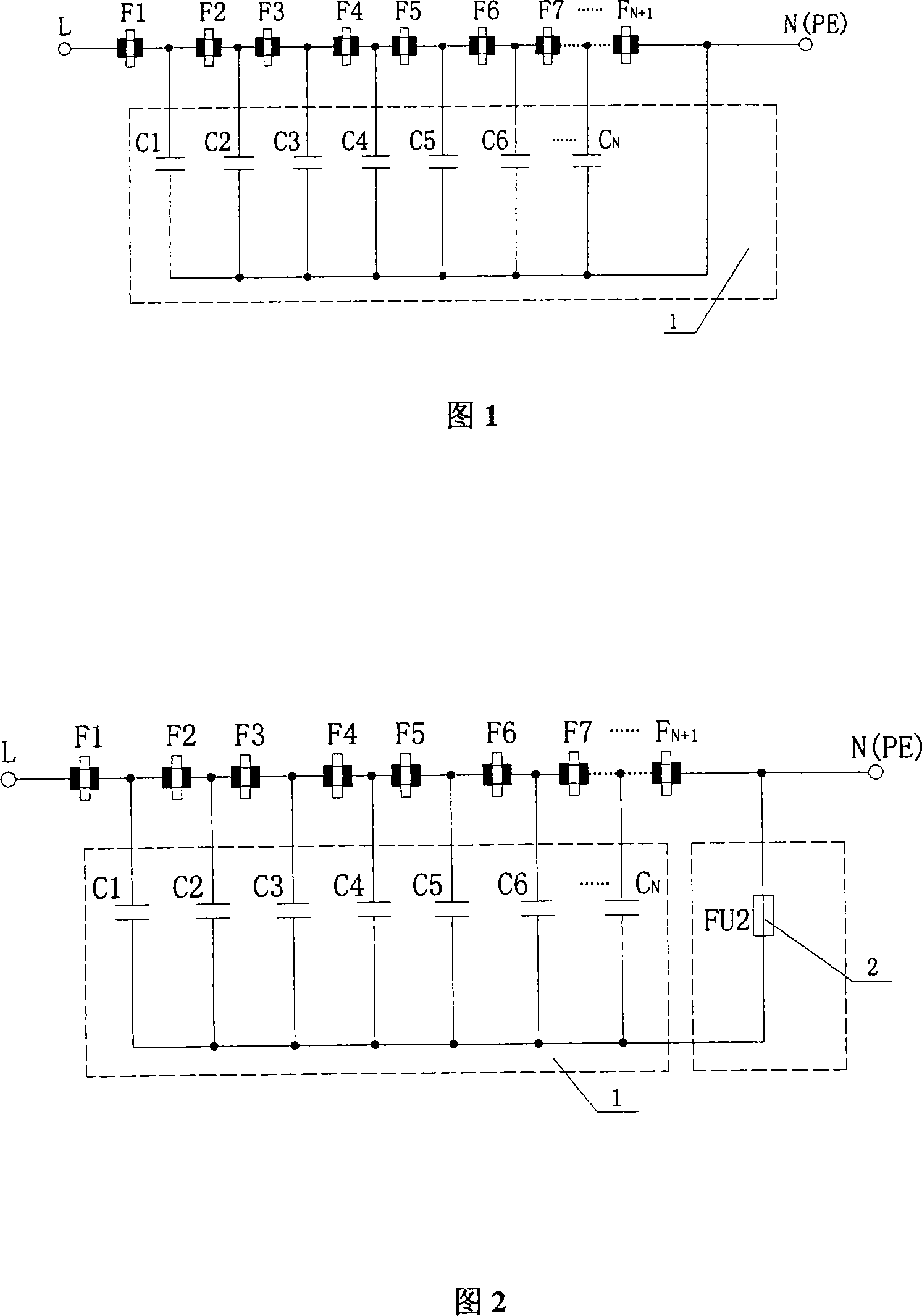

[0060] The circuit structure of the high-efficiency graphite stacked discharge gap device in this embodiment is shown in Figure 1, including nine graphite discharge gaps and a π-shaped connection capacitor group 1 composed of eight capacitors with the same capacitance value, and each graphite discharge gap is connected in series , where the first graphite discharge gap F 1 Connect with live wire, the last discharge gap F 9 Grounding, one end of each capacitor in the π-shaped connection capacitor group is connected to the conductive member between the two graphite discharge gaps, and the other end is grounded.

[0061] In the above circuit, the value of each capacitor of the π-shaped connection capacitor group is determined according to C=In / 2πfVK, where In=I / N=3.2 / 8A, f≈18×10 3 Hz, V=3000V, K=3, into the above formula calculation, C≈390pF.

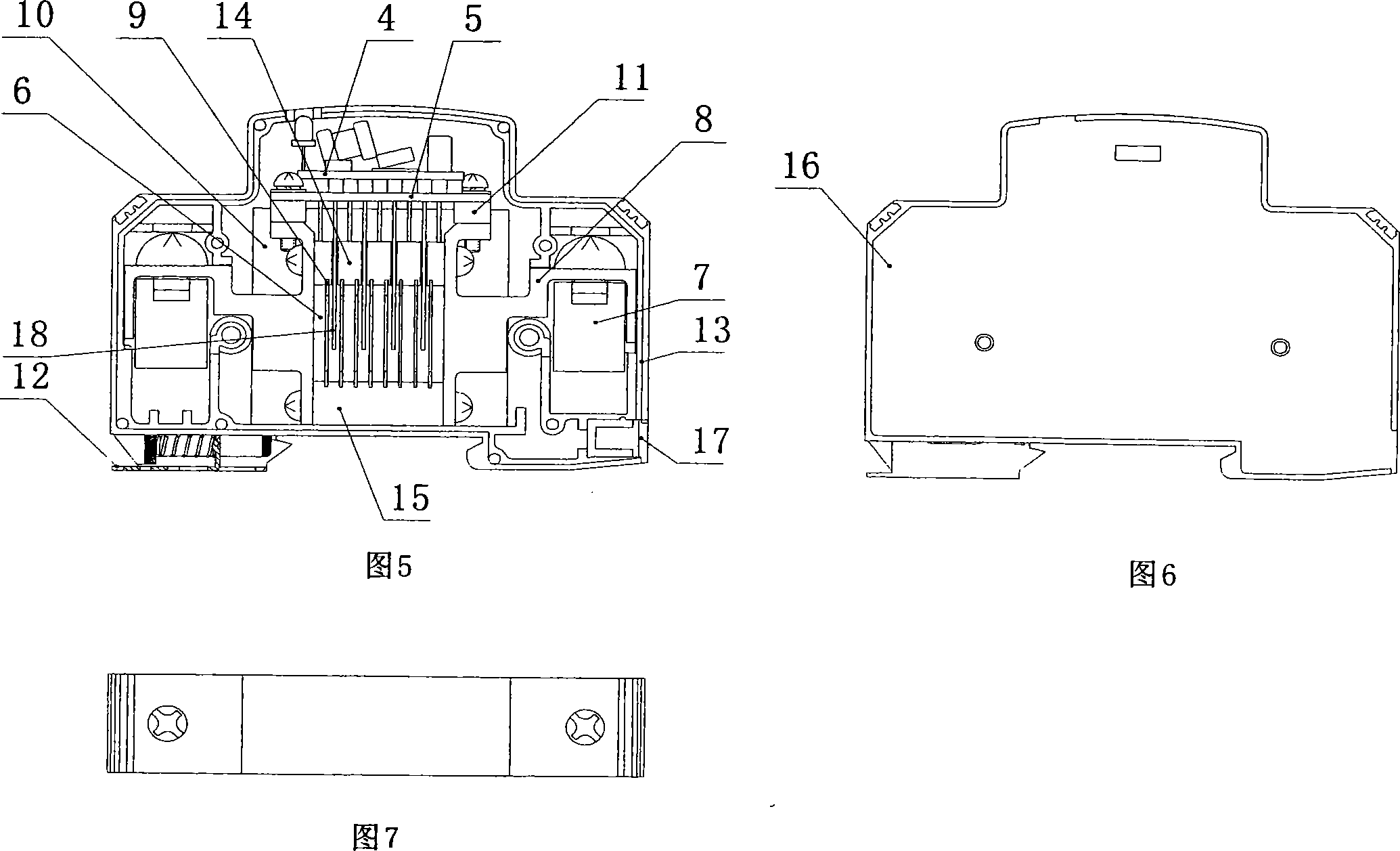

[0062] The electronic components in the above-mentioned circuit are assembled in the box body 13 shown in Figure 5, the size of the box...

Embodiment 3

[0065] The circuit structure of the high-efficiency graphite laminated discharge gap device in this embodiment is shown in Figure 2, including ten graphite discharge gaps, a π-connected capacitor group 1 composed of nine capacitors with the same capacitance value, and a current fuse 2. Each graphite discharge gap is connected in series, wherein, the first graphite discharge gap F 1 Connect with live wire, the last discharge gap F 10 Grounding, one end of each capacitor in the π-shaped connection capacitor group is connected to the conductive member between the two graphite discharge gaps, the other end is grounded, and the end of the π-shaped connection capacitor group circuit is connected to the current fuse 2 .

[0066] In the above circuit, the value of each capacitor of the π-shaped connection capacitor group is determined according to C=In / 2πfVK, where In=I / N=4.5 / 9A, f≈18×10 3 Hz, V=3000V, K=2, into the above formula calculation, C≈737pF.

[0067] The electronic compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com