Varied fuel cell oxidant flow channel depth resulting in fewer cooler plates

A fuel cell and fuel cell stack technology, applied in the directions of fuel cell additives, fuel cells, fuel cell grouping, etc., can solve problems such as affecting the water balance of fuel cell stacks, shortening the life of membranes or other temperature-sensitive components, etc. The effect of air utilization, size reduction, maintaining average temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

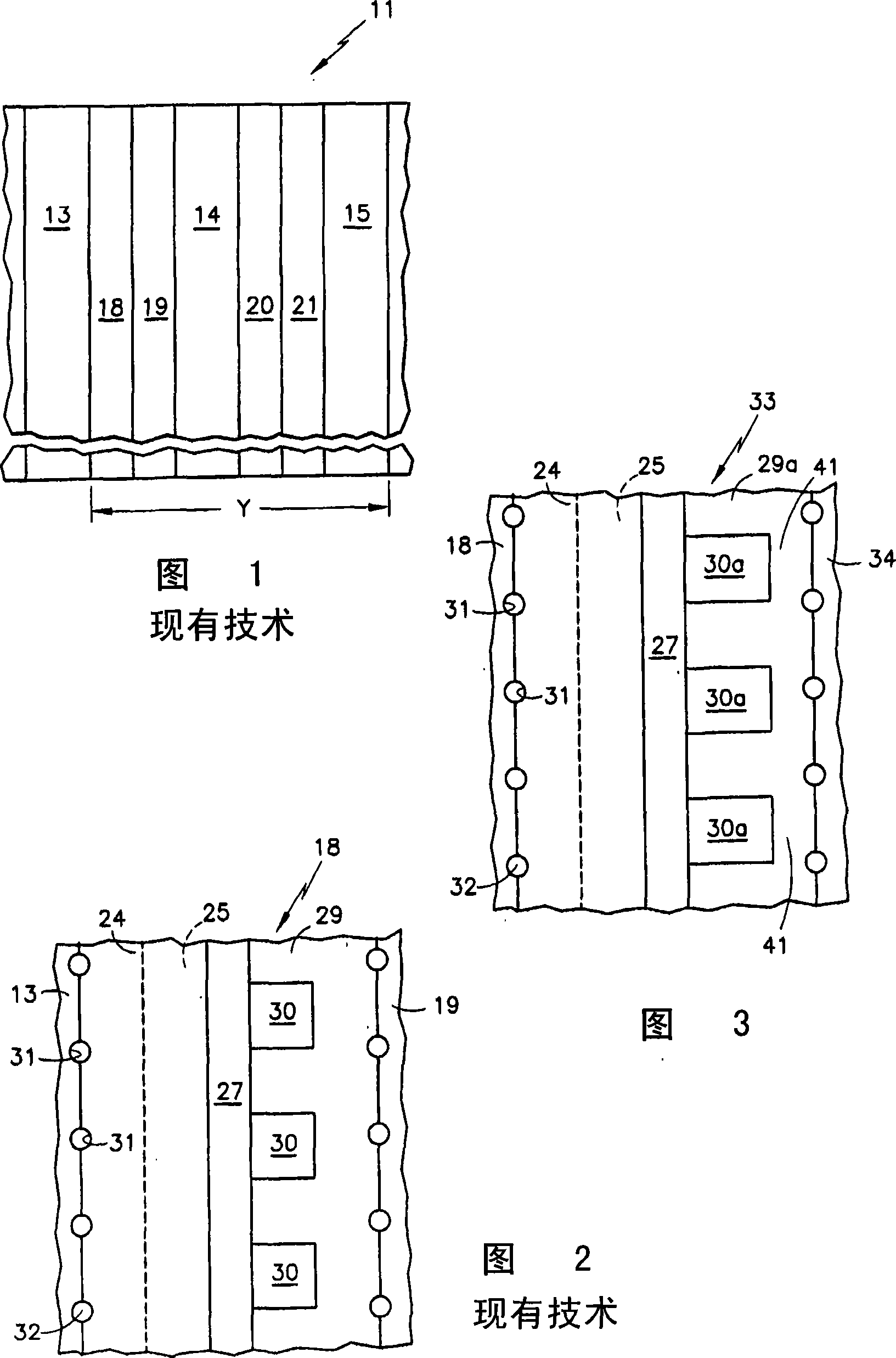

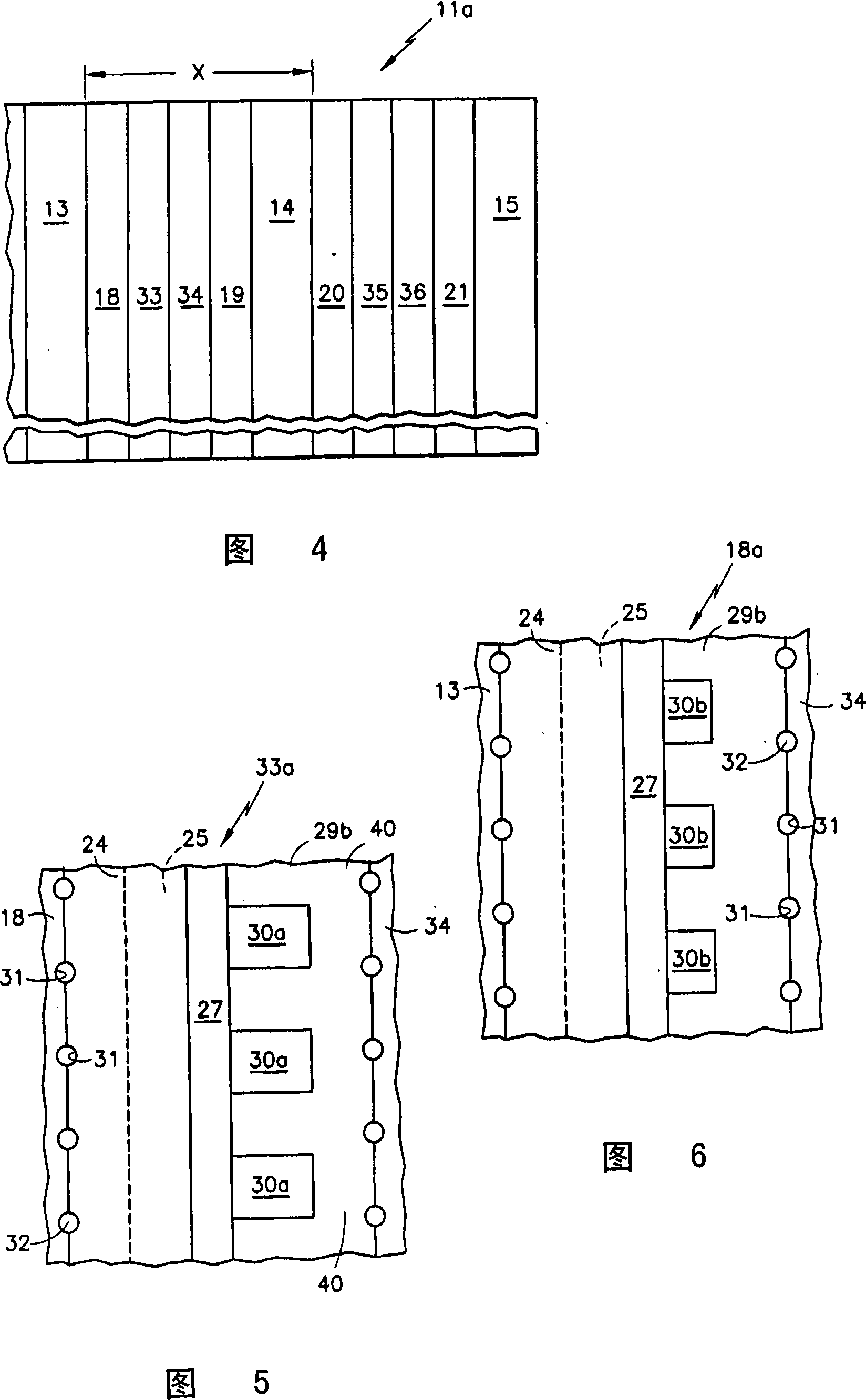

[0016] Referring to FIG. 1, fuel cell stack 11 includes a plurality of cooler plates, cooler plates 13-15 being shown. The fuel cell stack 11 also includes a large number of fuel cells, only fuel cells 18-21 being shown. Each of the fuel cells 18-21 is adjacent to one of the cooler plates 13-15 such that there are only two fuel cells between each pair of cooler plates.

[0017] The fuel cell 18 is exemplary and not drawn to relative or precise scale. Each fuel cell includes a hydrophilic porous fuel gas reactant flow field plate 24 with hydrophilic porous fuel flow field channels 25 disposed therein. Each fuel cell also includes an electrolyte assembly 27, which in the case of a proton exchange membrane, a polymer electrolyte membrane (PEM) fuel cell, includes a membrane and a catalyst on either side thereof. Each fuel cell also includes an oxidant gas flow field plate 29 that includes an oxidant gas flow channel 30 . Each reactant gas flow field plate 24 , 29 has a groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com