Method for greening side slope in type of blowing spraying alien earth improved by basal discs of growing plant

A technology of base plate and slope, applied in the field of slope greening, can solve the problems of high cost of planting base material, failure of slope greening, etc., and achieve the effects of simple production and processing technology, low cost and good source of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

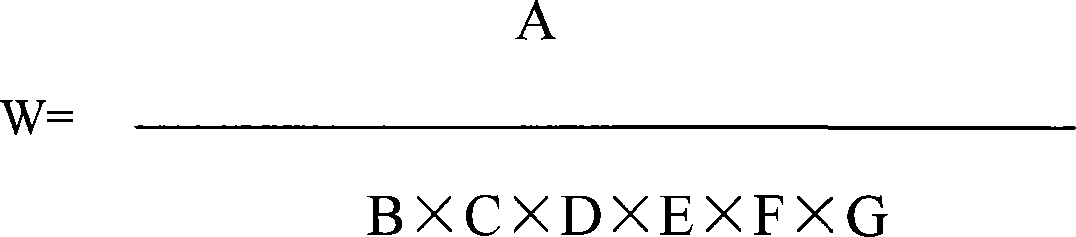

Image

Examples

Embodiment 1

[0026] Embodiment 1, a kind of planting-based plate material improvement guest soil spray type slope greening method, carry out the following steps in sequence:

[0027] 1. First make the plant base plate: first mix 20 parts by weight of bark, 35 parts by weight of wood chips and 45 parts by weight of cow dung to form the base material I, and then put 10 kilograms of superphosphoric acid in each cubic meter of base material I Calcium and 0.8 kg of composite microbial bacterial agent are evenly mixed and fermented at room temperature for 50 days to form a plant-based plate; the prepared plant-based plate is used as a finished product.

[0028] 2. Production of planting materials: transport the above-mentioned planting base plate to the construction site, and collect mellow soil near the construction site with a pH value of 4 and particles smaller than 2 cm as guest soil. Then 50 parts by volume of the planting substrate, 48 parts by volume of guest soil and 2 parts by volume of...

Embodiment 2

[0040] Embodiment 2, a planting-based plate material improvement guest soil blowing type slope greening method, the following steps are carried out in sequence:

[0041] 1. First make the plant base plate: first mix 20 parts by weight of bark, 35 parts by weight of wood chips and 45 parts by weight of cow dung to form substrate I, and then put 9.5 kilograms of superphosphoric acid into substrate I per cubic meter Calcium and 0.75 kg of compound microbial bacterial agent are evenly mixed and fermented at room temperature for 60 days to form a plant-based substrate; the prepared plant-based substrate is used as a finished product.

[0042] 2. Production of planting materials: transport the above-mentioned planting base plate to the construction site, and collect mellow soil near the construction site with a pH value of 6 and particles smaller than 2 cm as guest soil. Then, 45 parts by volume of planting substrate, 53 parts by volume of guest soil and 2 parts by volume of soil pe...

Embodiment 3

[0044] Embodiment 3, a planting-based plate material improvement guest soil blowing type slope greening method, the following steps are carried out in sequence:

[0045] 1. First make the plant base plate: first mix 20 parts by weight of bark, 35 parts by weight of wood chips and 45 parts by weight of cow dung to form substrate I, and then put 10.5 kilograms of superphosphoric acid into substrate I per cubic meter Calcium and 0.85 kg of compound microbial bacterial agent are evenly mixed and fermented at room temperature for 45 days to form a plant-based substrate; the prepared plant-based substrate is used as a finished product.

[0046] 2. Production of planting materials: transport the above-mentioned planting base plates to the construction site, and collect mellow soil near the construction site with a pH value of 8 and particles smaller than 2 cm as guest soil. Then, 60 parts by volume of planting substrate, 40 parts by volume of guest soil and 2 parts by volume of soil pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com