Temperature control device of heating system in hot-forming machine for plastic sheet

A technology of temperature control device and thermoforming machine, which is applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of increasing temperature measurement signal input points, increasing manufacturing cost of temperature control device, and inability to obtain the temperature of heating bricks. Signal and other problems, to achieve the effect of reducing manufacturing costs, simple and easy operation, and ensuring temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

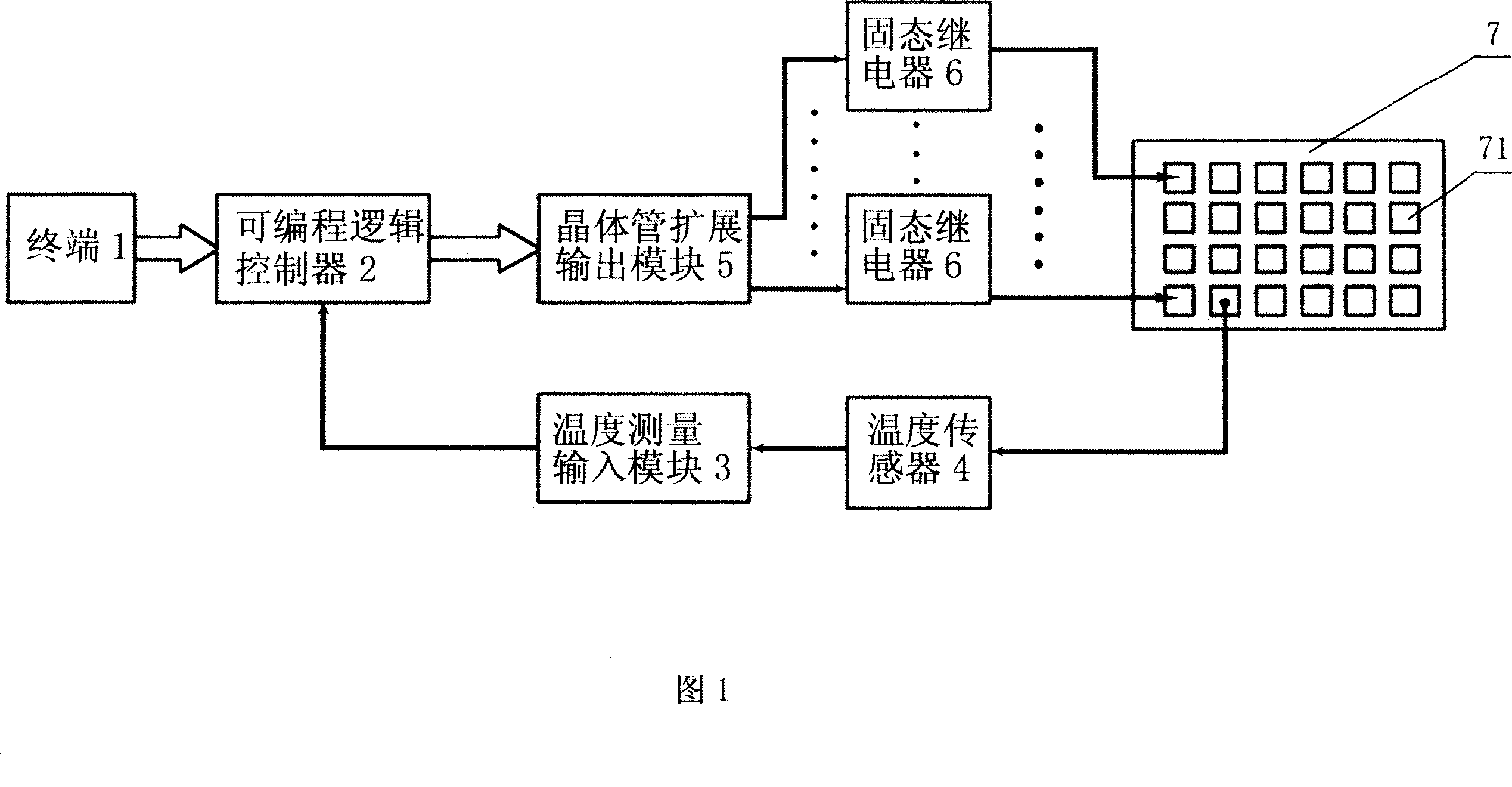

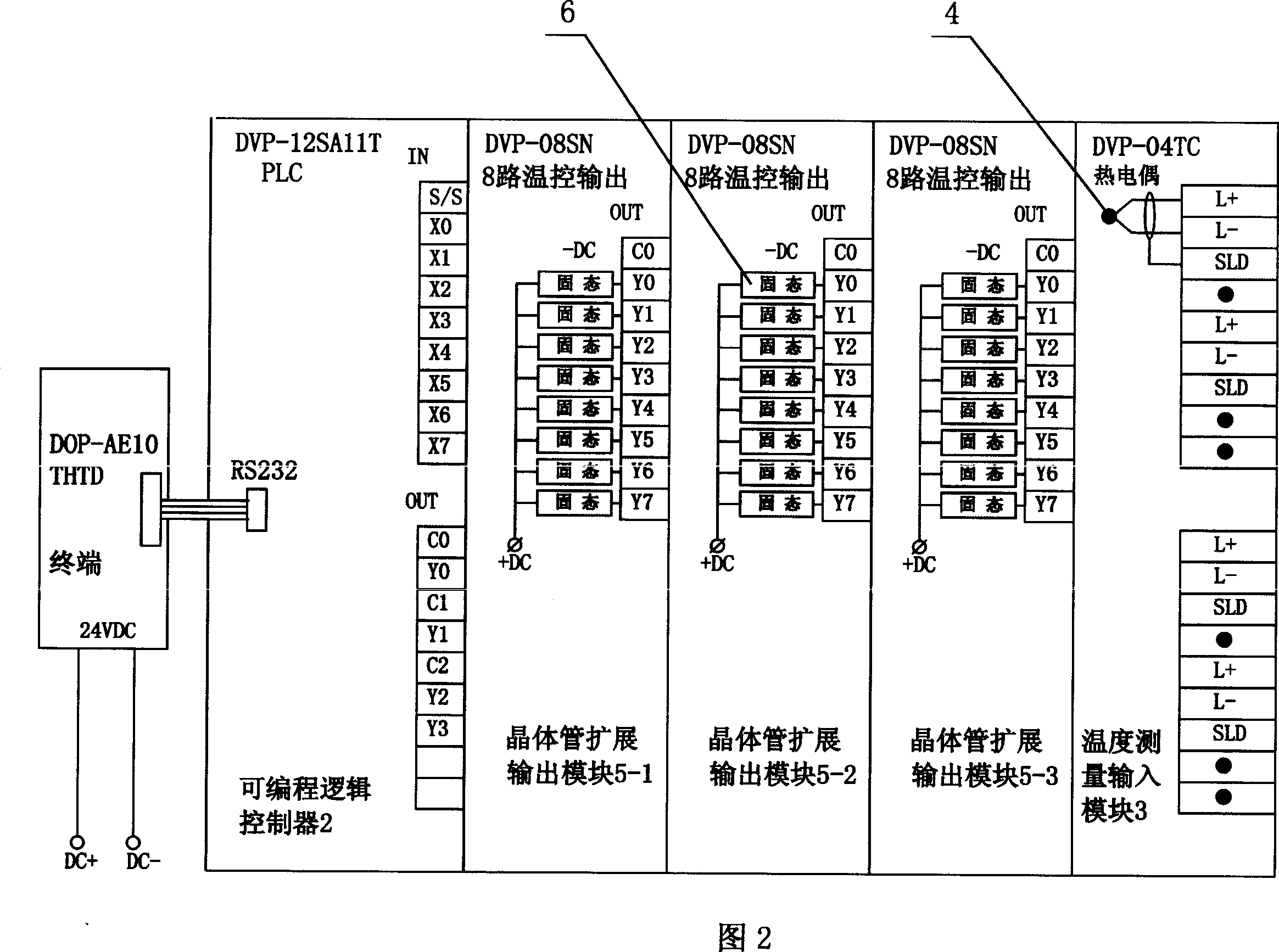

[0022] As shown in Figure 1, the temperature control device of the heating system of this plastic sheet thermoforming machine includes a terminal 1, a programmable logic controller 2, a temperature measurement input module 3, a temperature sensor 4, a transistor expansion output module 5 and a solid state relay 6, wherein the terminal 1 is connected to the programmable logic controller 2 through the interface; the temperature sensor 4 is connected to the input point of the temperature measurement input module 3; the temperature measurement input module 3 is connected to the programmable logic controller 2 through the interface; the transistor expansion output module 5 is connected with the programmable logic controller 2 through the interface, the output point of the transistor expansion output module 5 is connected with the solid state relay 6, each solid state relay 6 is connected with an output point of the transistor expansion output module 5, the quantity of the solid state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com