Technique for manufacturing packer with the tape-cutting handle setup independently

A manufacturing process and tape cutting technology, which is applied in the manufacturing process field of packaging devices, can solve the problems of short distance, inconvenient manipulation, complex structure, etc., and achieve the effect of easy manipulation, great industrial utilization value, and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

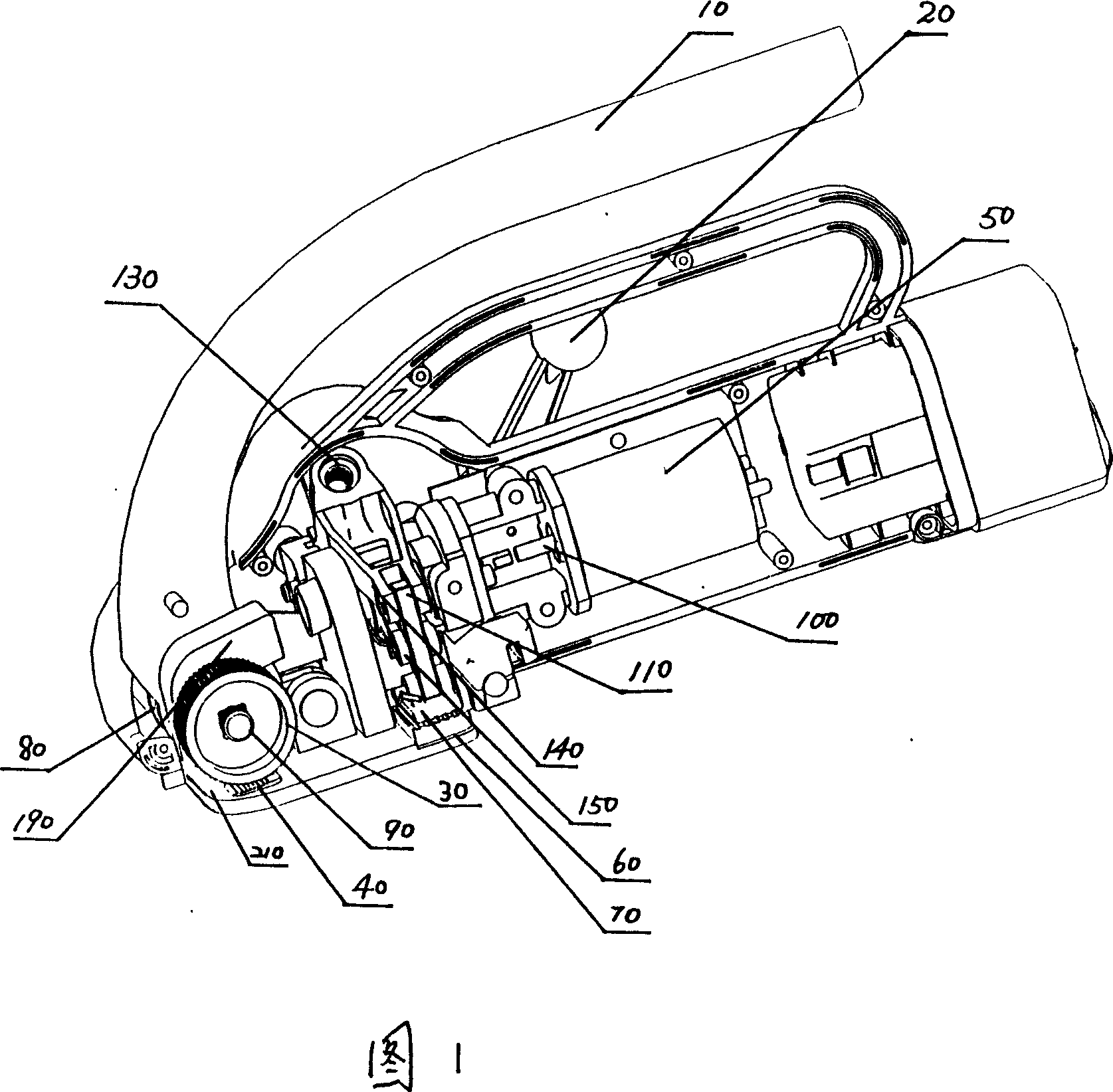

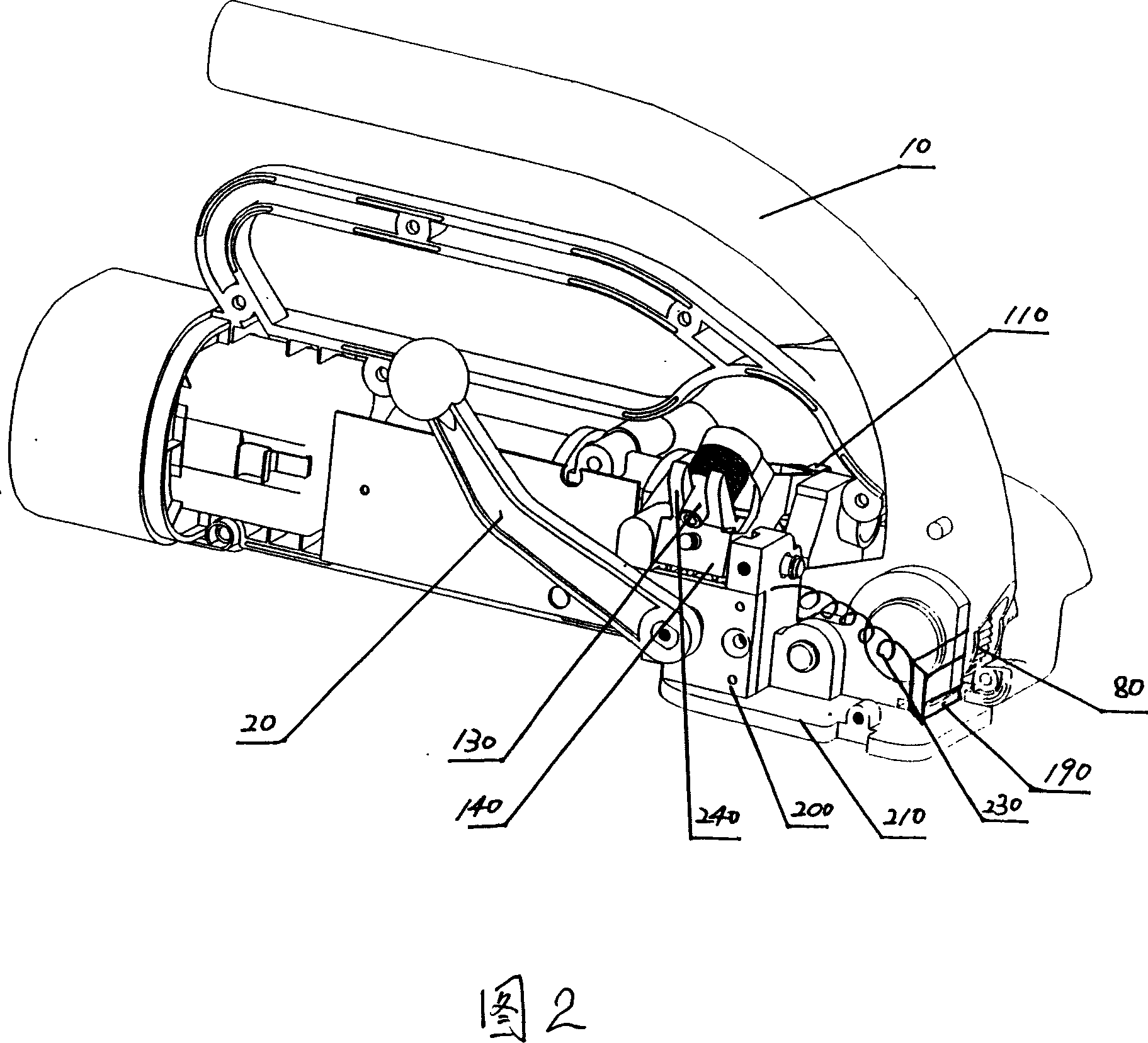

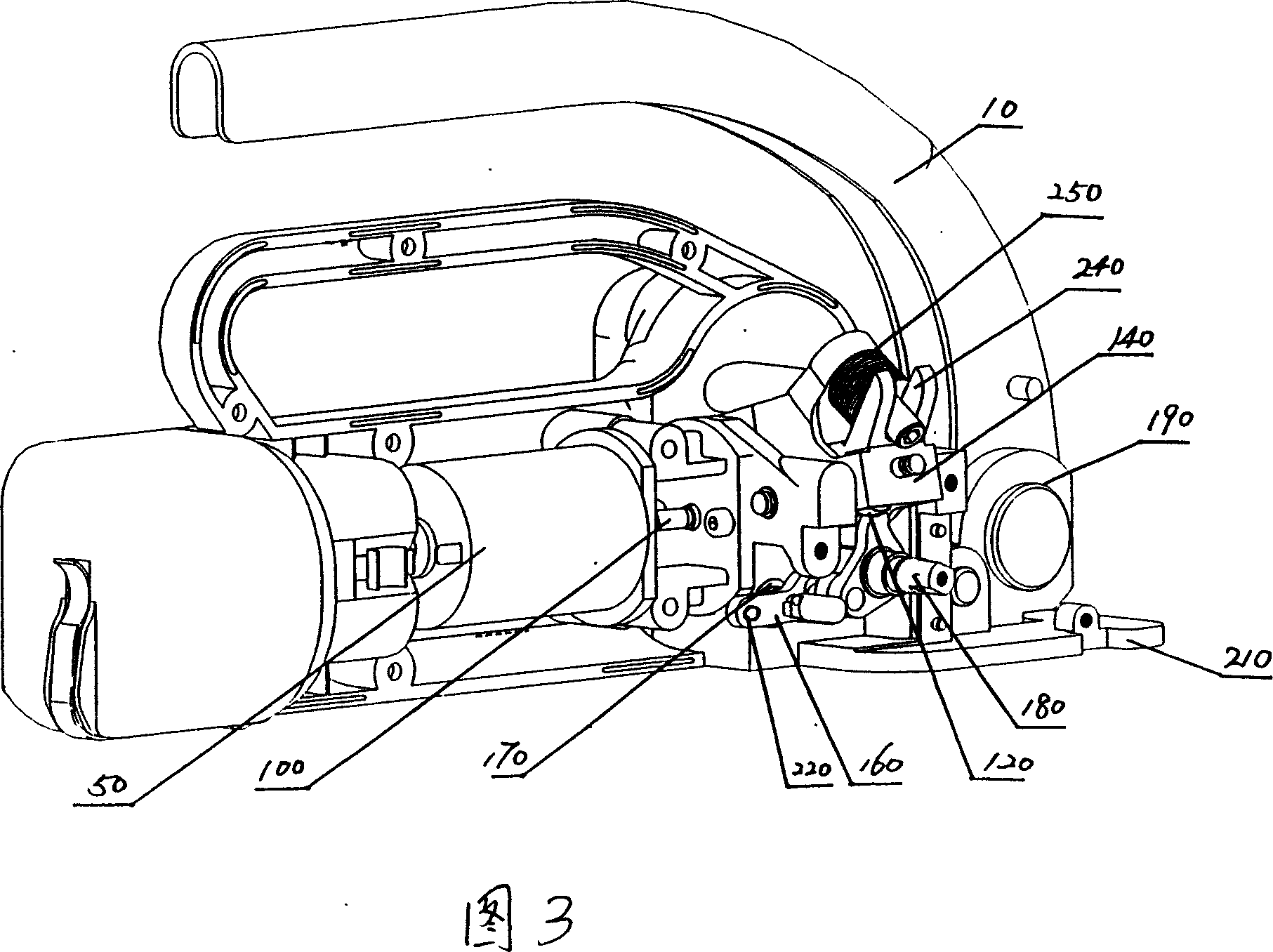

[0010] The invention relates to a manufacturing process of a baler with independent tape-cutting handles, which mainly includes the following steps: the provided tape-cutting handle is set on a camshaft. Below in conjunction with accompanying drawing, the structure of the packing machine that the tape cutting handle that the present invention manufactures is provided with independently is described in further detail. Referring to Fig. 1 , the connecting ear at the front end of the bottom plate 210 is connected to the pulley connector 190, and one end of the ratchet shaft 90 through which the pulley connector 190 passes is covered with a pulley 30, and the corresponding position under the pulley 30 is A pinch plate 40 is provided. The other end is sheathed with a ratchet 80, and the pressure and release handle 10 is connected to the ratchet 80 through a ratchet. Referring to FIG. 2 , the other side of the pulley connector 190 is connected to the wallboard 200 on the bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com