Composition, compound body, and method for raising utilization ratio of catalyst

A utilization rate and composite technology, applied in chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., can solve the problem of low catalyst utilization rate, catalyst particles displacing polymers, and failure to consider the adsorption of polymers and catalyst particles sexual issues

Active Publication Date: 2010-11-10

IND TECH RES INST

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, the research on the preparation of catalyst slurry only considered adding dispersion energy to the equipment, adjusting the type and viscosity of the solvent, adjusting the solubility between the polymer and the solvent, or using a surfactant, but did not consider the relationship between the polymer and the catalyst particles. The problems faced by the adsorptive properties include: (1) Catalyst particles are easy to aggregate and discharge polymers; (2) Phase separation and cracks occur in the coating / drying process; the only solution is to solve the adsorptive properties of polymers and catalysts. Therefore, solving the problem of low utilization rate of catalysts from the force between polymers and catalyst molecules has become a topic worthy of research

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

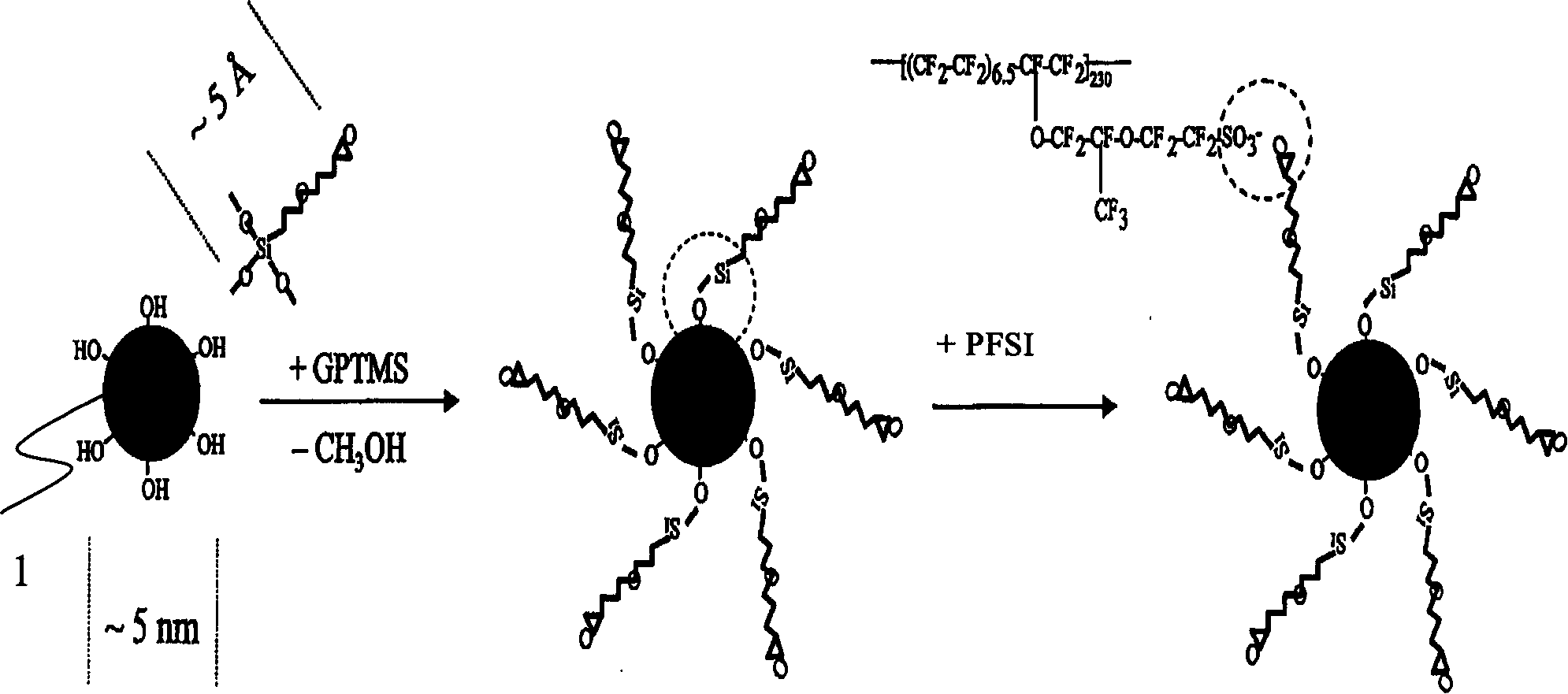

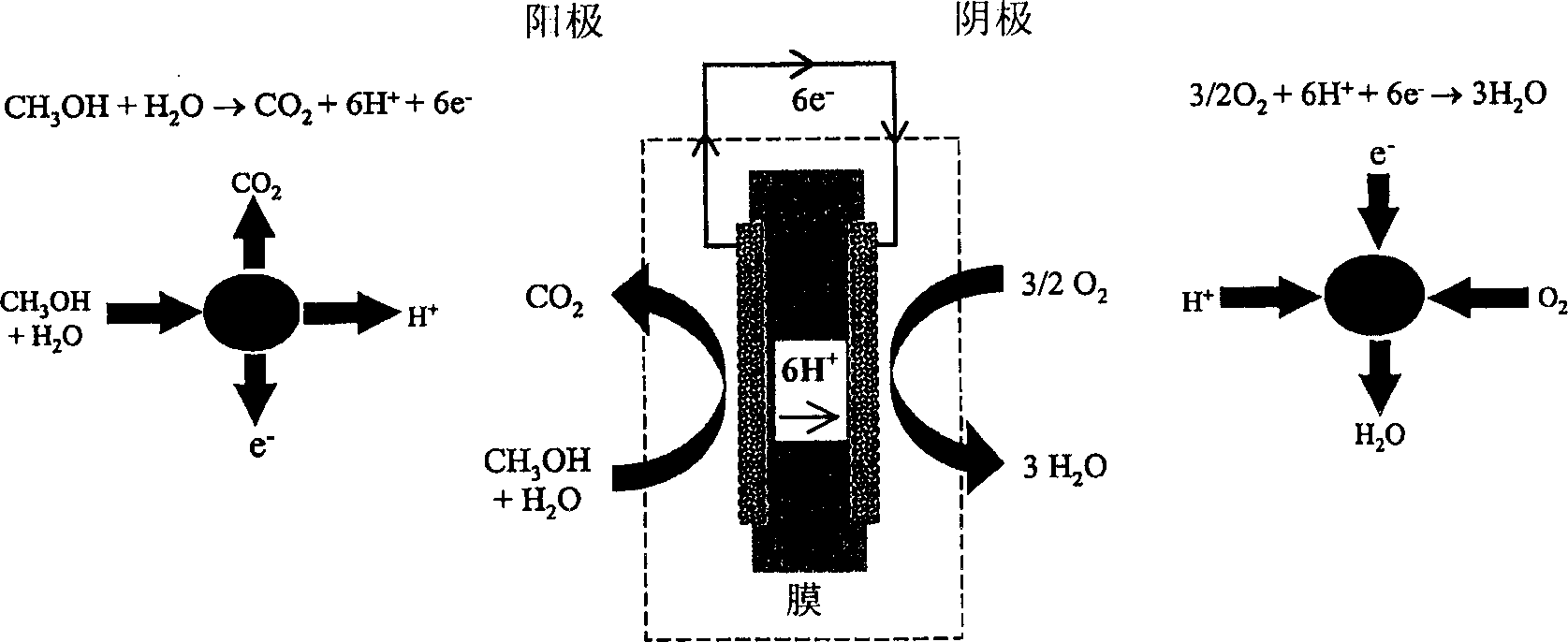

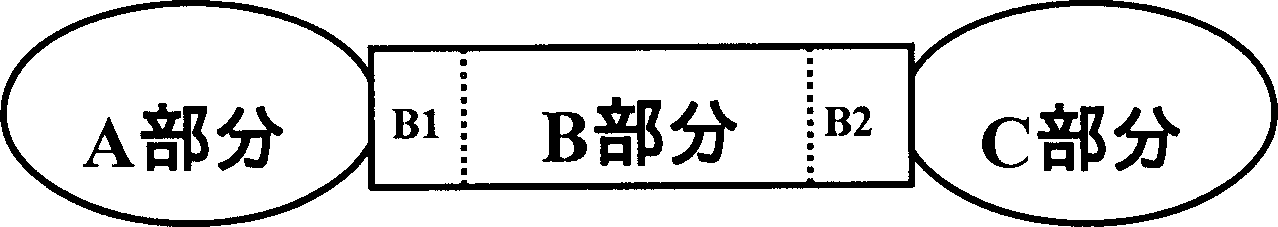

The invention discloses a composition for raising use ratio of catalyst for fuel cell. The composition includes catalyst, ion macromolecules of proton conduction, and couplant. Using function group B1, the couplant binds catalyst or carrier of catalyst; and using function group B2 the couplant binds ion macromolecules of proton conduction. The invention also discloses corresponding method including following steps: (1) using supersound to break up catalyst; (2) adding couplant to generate bonding to catalyst; and (3) adding high molecular fluoride to generate bonding to couplant so as to formcomposition of catalyst - couplant - high molecular fluoride in order to form stable dispersion. In step (2), the couplant uses a function group B1 to bond to catalyst, and uses a function group B2 to bind to high molecular fluoride.

Description

Compositions, complexes and methods for improving catalyst utilization technical field The invention relates to a composition and method for improving the utilization rate of fuel cell catalysts, especially a compound formed by adding a coupling agent to bond catalysts and polymers, and utilizing the original necessary components of the catalyst slurry Composition and method for stably dispersing polymer fluoride to improve fuel cell catalyst utilization. Background technique Fuel cell (FuelCell) is one of the most feasible methods to solve energy problems and environmental pollution in the future due to its high conversion efficiency, no pollution, and fast refueling. The Direct Methanol Fuel Cell (DMFC), which directly adds methanol as fuel, has great potential in the application of portable electronic products. In the current development of fuel cell technology, only the precious metal Pt is the most suitable catalyst. However, Pt is the only material that cannot be m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M8/02H01M4/90H01M4/92C08L101/04C08K5/541B01J32/00H01M4/86H01M8/0202

CPCY02E60/50

Inventor 吴富其蔡丽端薛康琳雍敦元黄秋萍张嵩骏

Owner IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com