Program controlled peeling machines

A program-controlled peeling machine and pig skin technology, which can be used in peeling tools and other directions, and can solve the problems of mixed pig breeds and large size disparities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

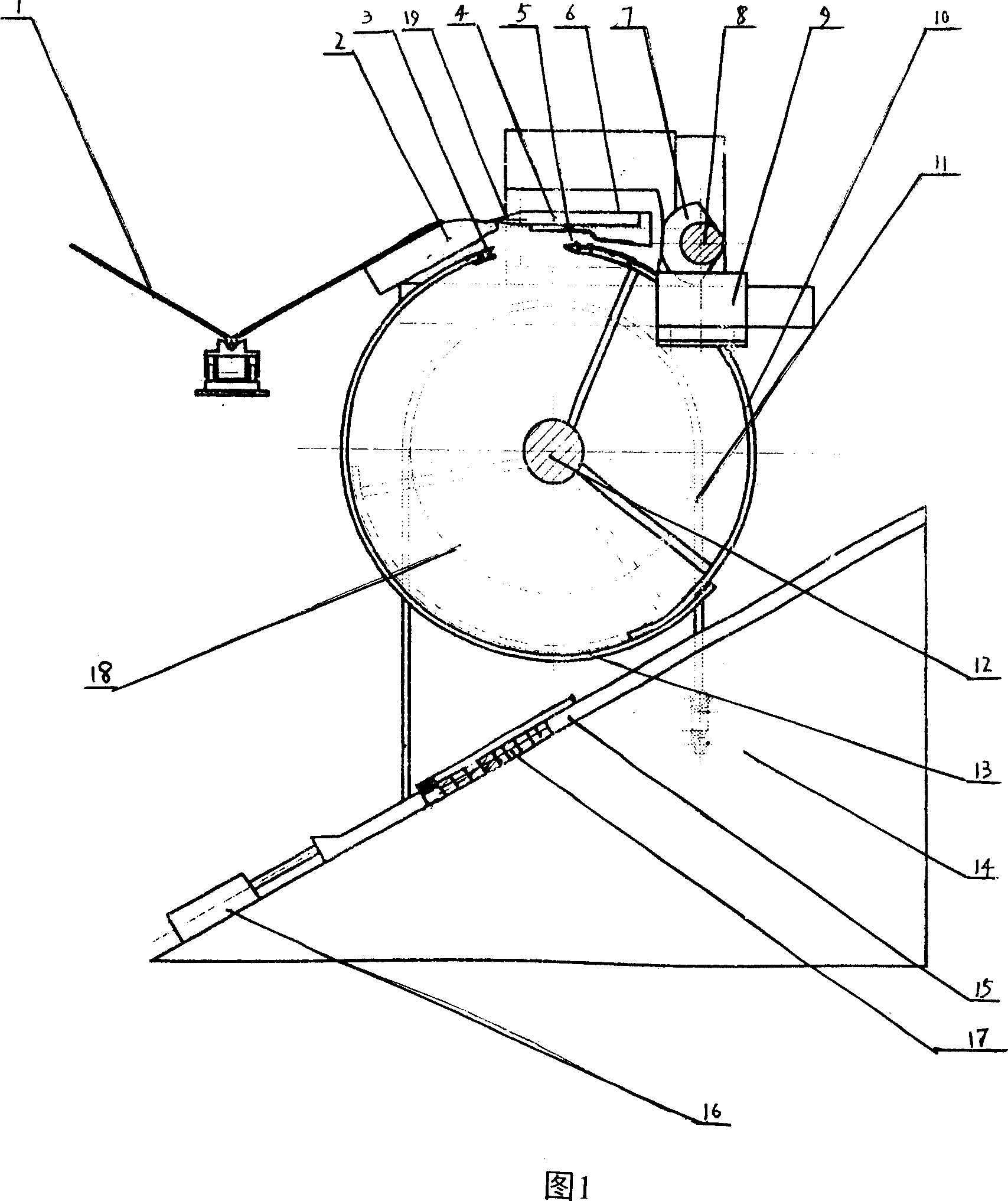

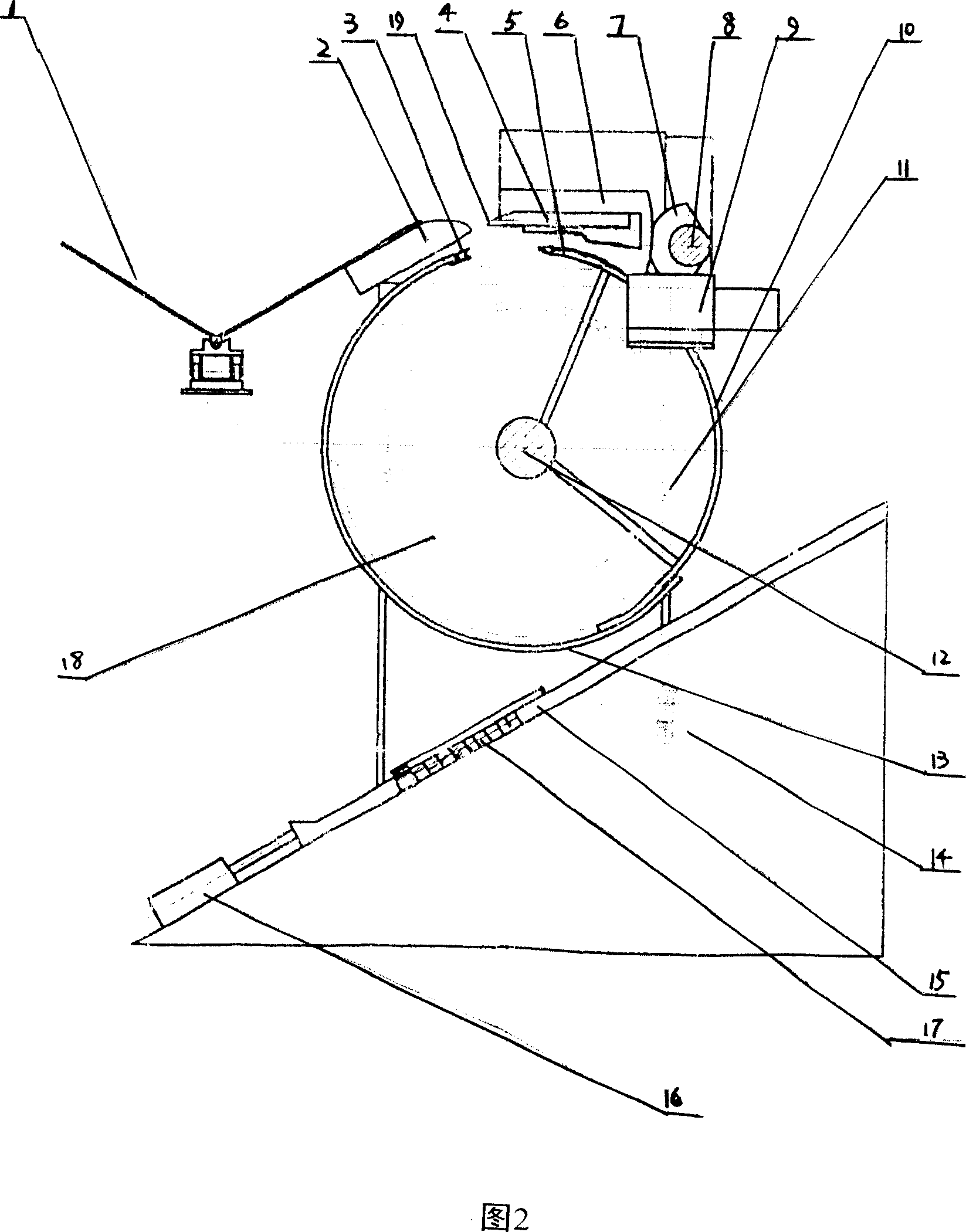

[0009] As can be seen from the figure, the workman pushes the pig body above the conveyor belt (1) against the arc-shaped backing plate (2) and puts the pre-peeled pigskin limit into the front of the sandwich groove (3). The start-up worker first jogs the hydraulic device to lift the peeling machine so that the skinning groove is 2cm higher than the edge of the pigskin to be clipped, and then according to the thickness of the pigskin to be peeled, select the 8 selection buttons in order from thin to thick (also power supply Start button) Select one and slide the knife box assembly to the working position and hold it still. Like this microcomputer gives the variable frequency speed regulation motor simultaneously according to the girth that electronic ruler side decides and the thickness that is selected, and drum running motor, peeling knife vibrating motor has started respective operation program. The drum motor shaft (12) with the inner drum (10) presses the leather knife (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com