Semiconductor device and its making method

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as weak connection strength, increased manufacturing costs and difficulties of semiconductor devices, and achieve accurate photosensitive or Effects of imaging, improvement of in-plane uniformity, and increase in manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

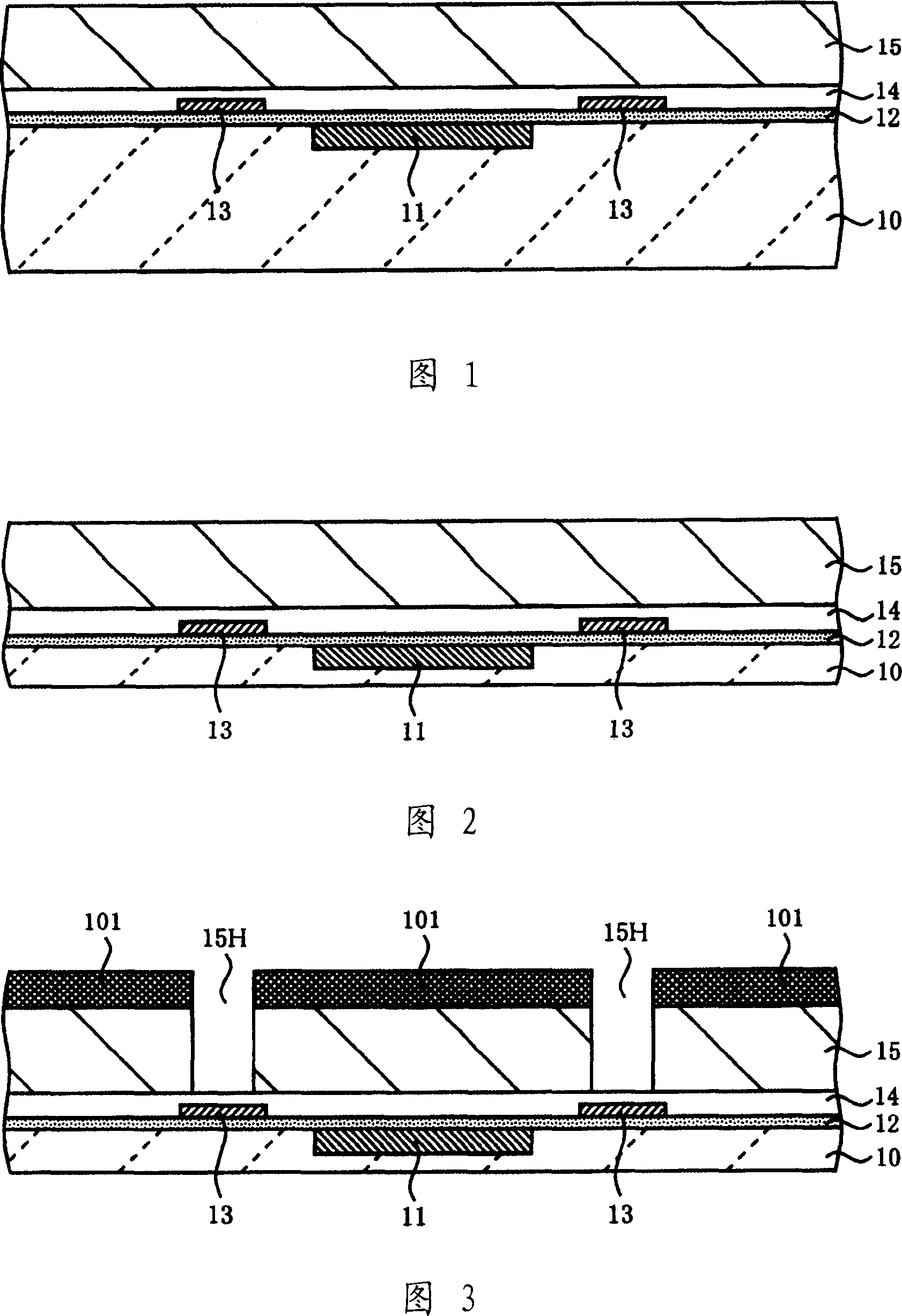

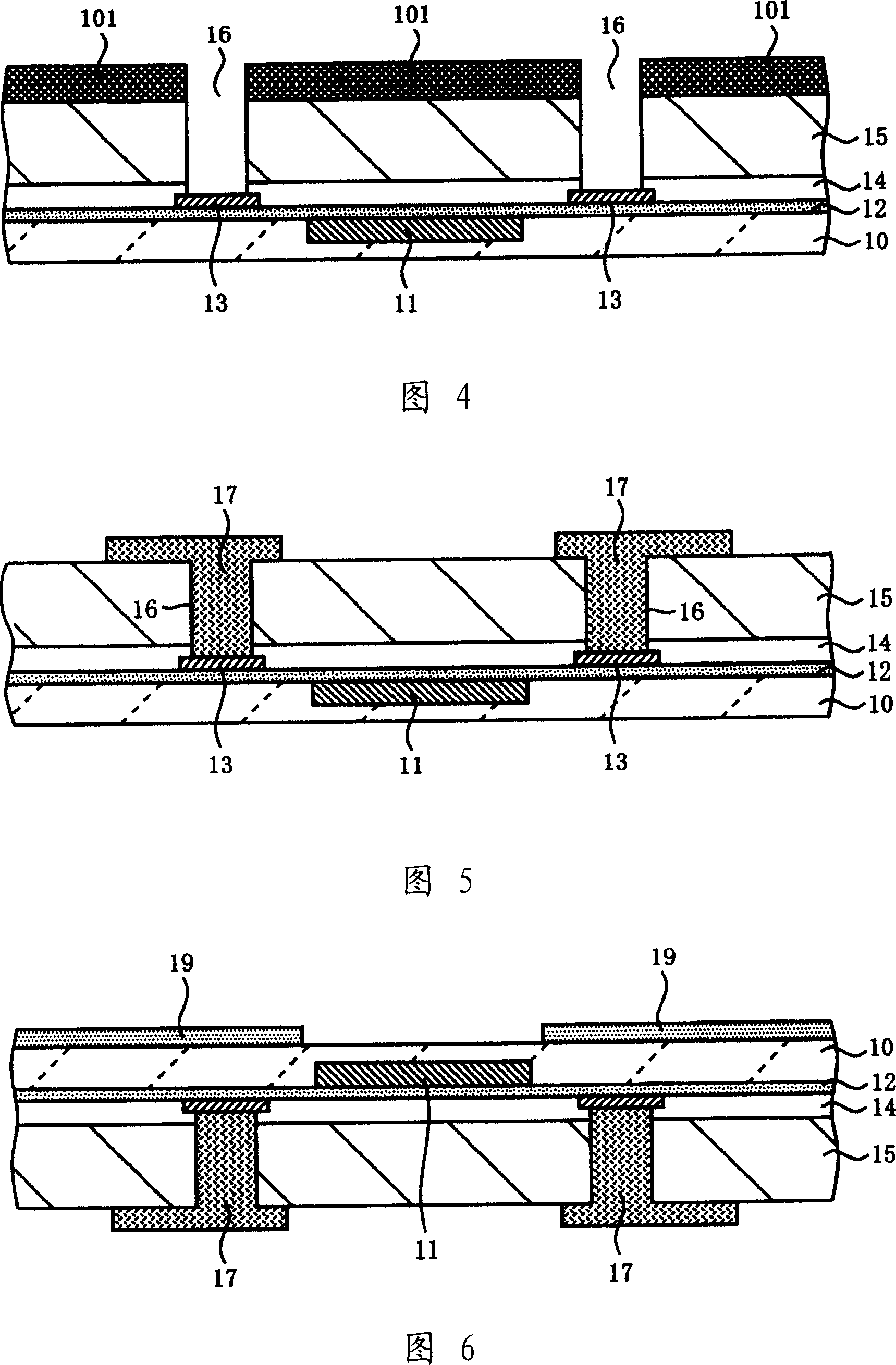

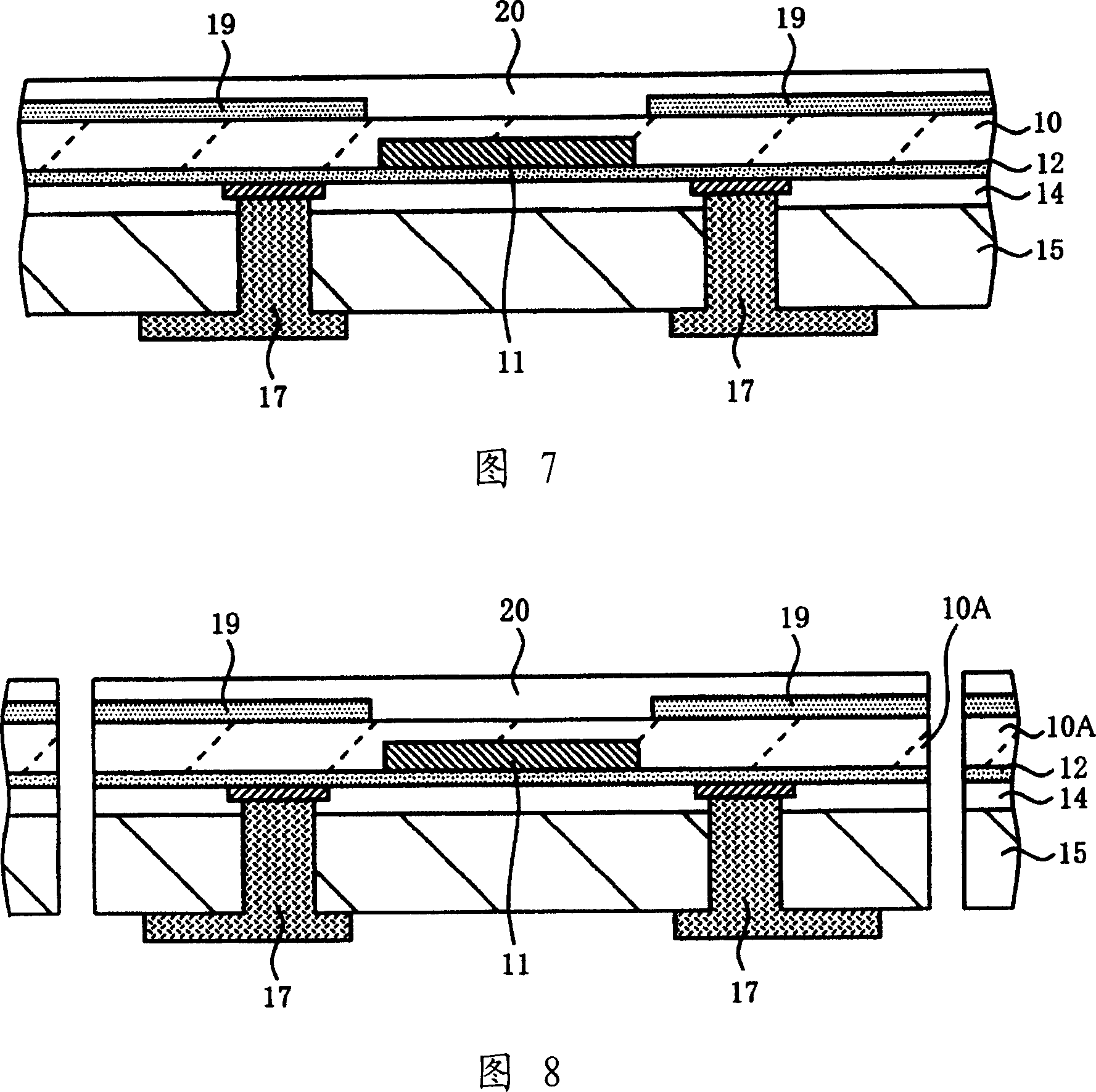

[0028] Next, a semiconductor device according to an embodiment of the present invention will be described with reference to the drawings. The manufacturing method of the semiconductor device of this embodiment is performed as follows, for example. 1 to 8 are cross-sectional views illustrating a method of manufacturing a semiconductor device according to this embodiment. In addition, FIG. 9 is a cross-sectional view illustrating the semiconductor device and its manufacturing method according to the present embodiment.

[0029] In addition, FIGS. 1 to 9 show cross-sections of semiconductor substrates at predetermined adjacent chip boundaries (that is, near scribe lines not shown) separated by a dicing process described later.

[0030] First, as shown in FIG. 1 , a photosensitive element such as a CCD (Charge Coupled Device) is formed on the surface of a semiconductor substrate 10 made of a silicon substrate as a photosensitive element. The CCD 11 is not particularly limited, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com