Car ceiling waste material cutting machine

A car roof and cutting machine technology, applied in metal processing, etc., can solve the problems of occupying several waste storage vehicles, high labor intensity of workers, and low production efficiency, so as to improve production efficiency, reduce labor intensity of workers, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

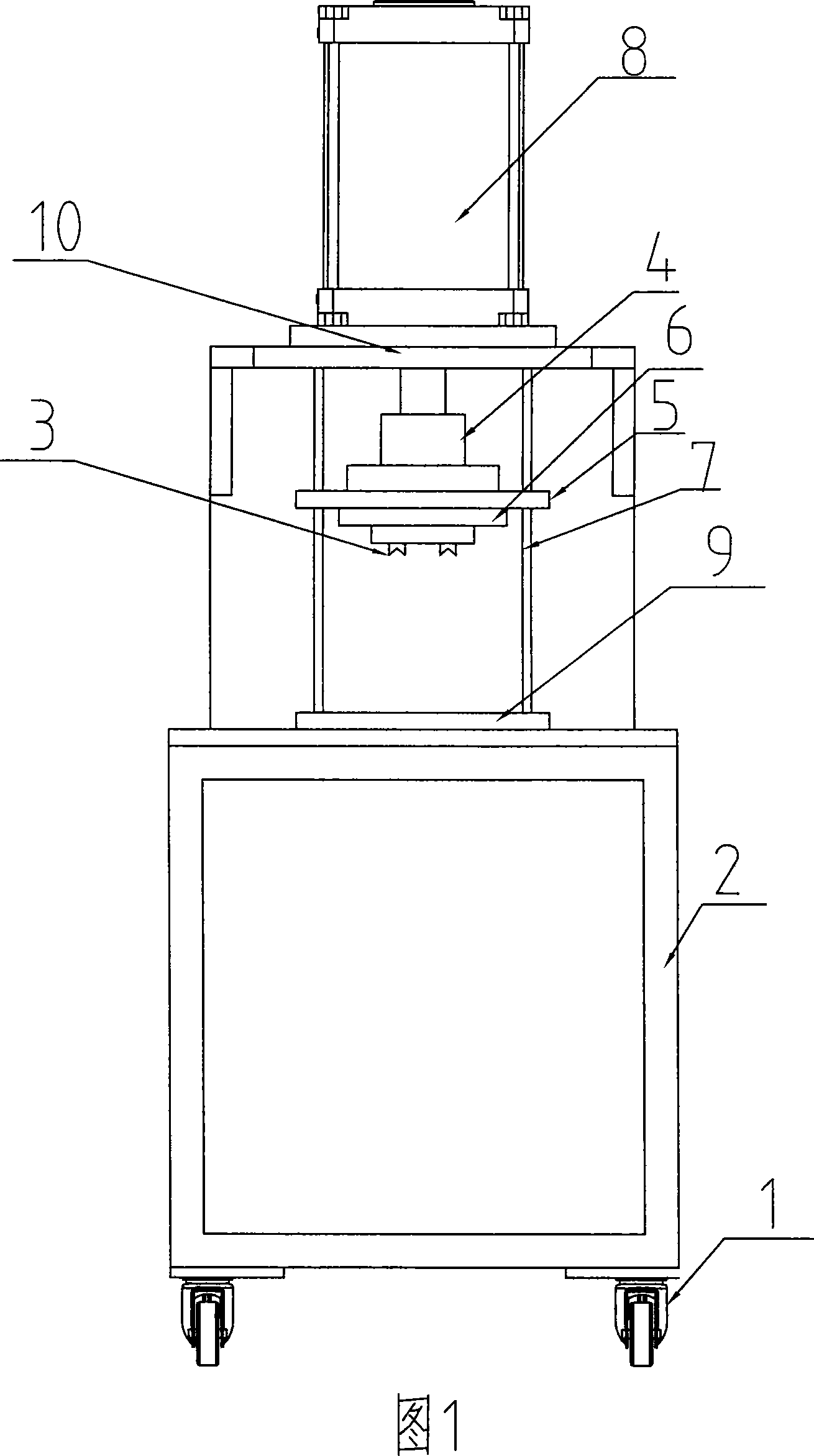

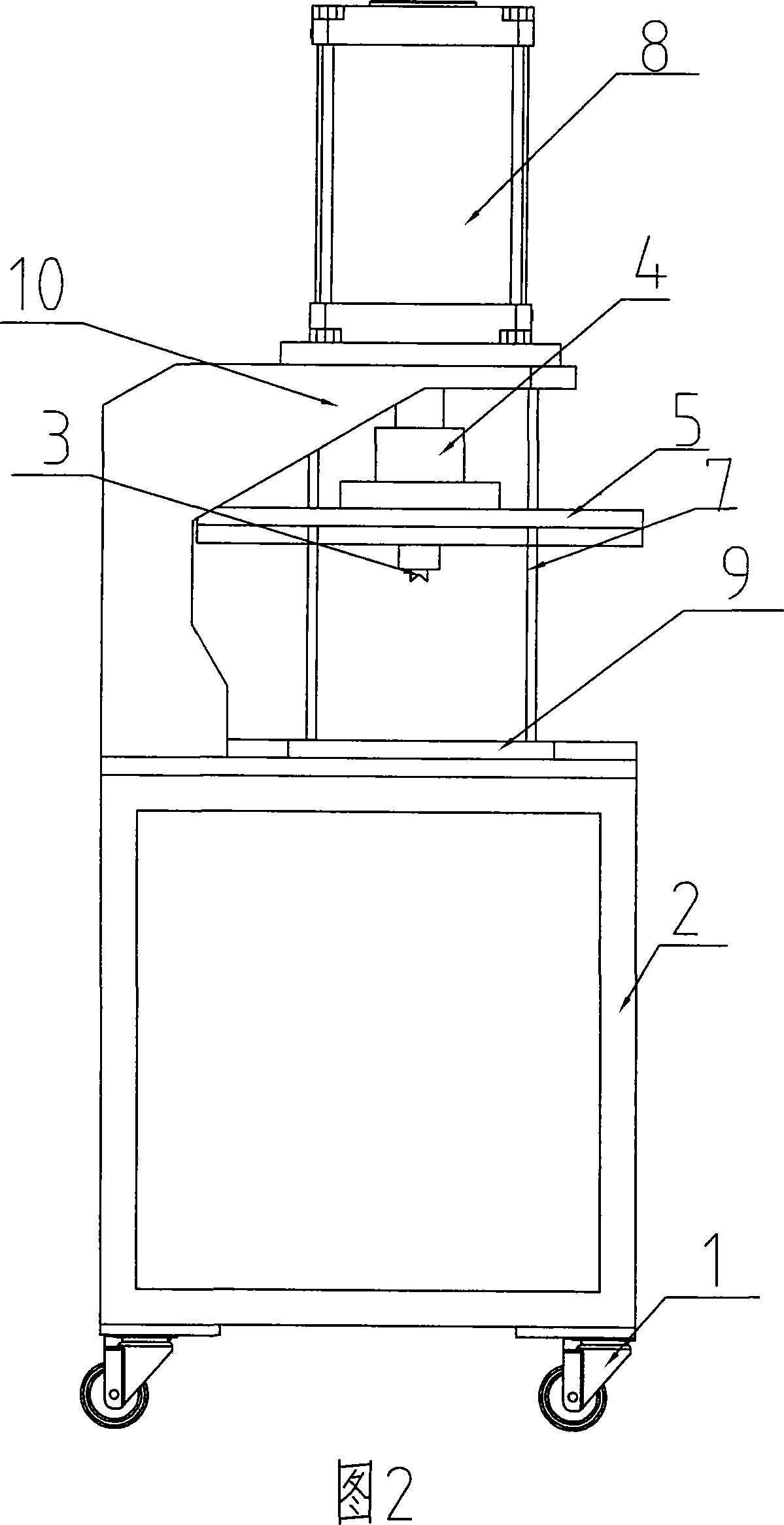

[0010] The present invention is mainly made up of walking wheel 1, table frame 2, cutting tool 3, axle sleeve 4, cutting die pressing plate 5, cutting die 6, cutting die guide sleeve 7, cylinder 8, nylon backing plate 9 and the like.

[0011] As shown in the figure: there is a cylinder 8 on the bracket 10, a backing plate 9 on the bottom of the bracket 10, a die 6 at the end of the piston rod of the cylinder 8, and a guide for the die 6 on the bracket 10 Die cutter guide rod 7. The table frame 2 is arranged below the support 10, and the backing plate 9 is positioned at the top of the table frame 2 facing the knife mold 6, and the traveling wheels 1 are arranged below the table frame 2. The lower end of piston rod has axle sleeve 4, and between axle sleeve 4 and die die 6, die die pressing plate 5 is arranged, and the both sides of die die pressing plate 5 have guide holes that are respectively enclosed within die die guide rod 7.

[0012] When working, first place the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com